89

Fig. 63 Unacceptable cross-sectional constriction

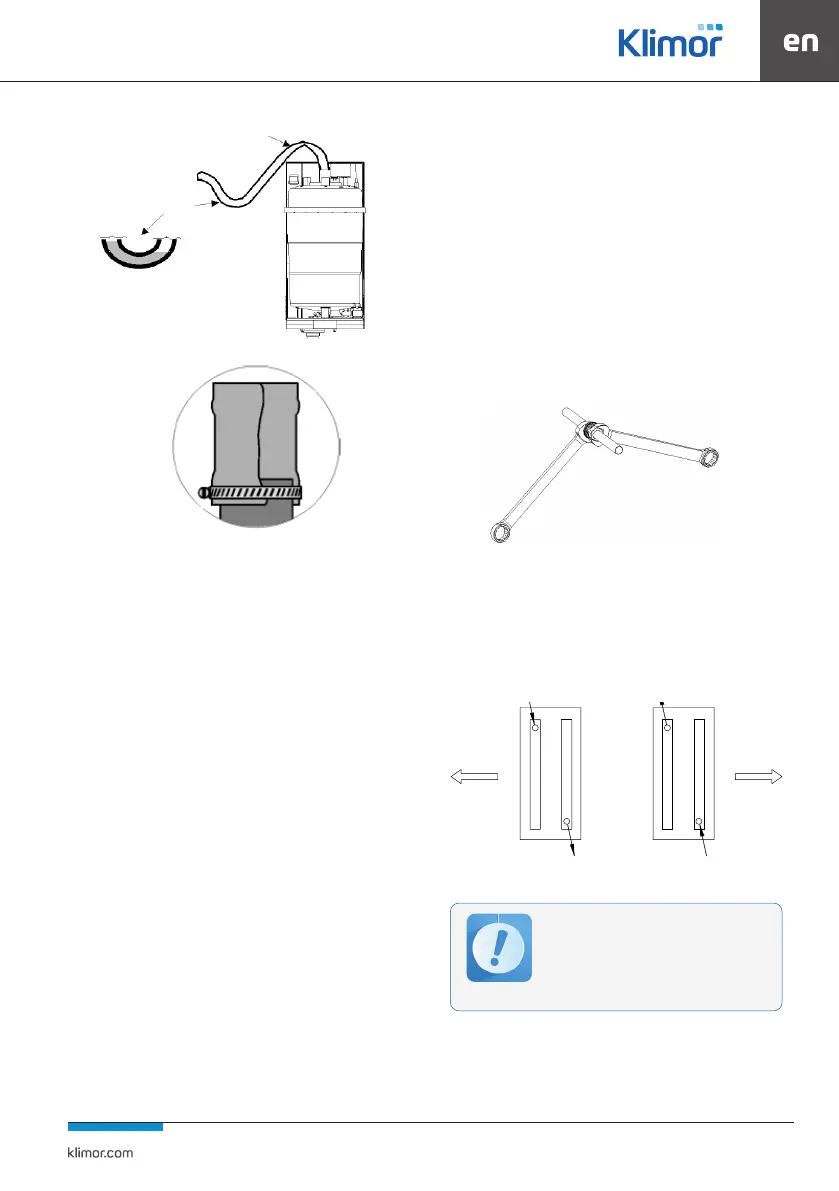

Fig. 64 Installation of cable with clamps

4.7.2 Operation of humidiers

Clean and check the humidiers every 12m before the he-

ating season.

Wash the humidication sections with warm water and de-

tergent. In the case of marks of sedimentation in the drip tray,

wash it with water with the addition of a descaling agent.

Maintenance and service of the steam generator should be

carried out according to the manufacturer’s individual docu-

mentation.

4.8 WC and DX Cooling

The task of water and glycol coolers and direct evaporation

of DX is to reduce the air temperature to that required by

the design data.

A standard cooler consists of a galvanized sheet steel casing

and a CuAl package with copper tubes and aluminium ns.

The collectors and stubs are made of copper or steel.

The water and glycol exchanger is equipped with drain and

vent plugs. During installation of the hydraulic system, it is

recommended to add draining and venting valves to the

pipes led to the exchanger. When connecting the coolers

to the supply system, it is necessary to follow the recom-

mendations from chapter 4.8.1. Behind the cooler there is

acondenser for catching water drops.

For the sectional coolers, in the double exchanger version,

the condenser is mounted behind the second cooler.

Under the cooling block there is a drip tray with a stub for

condensate drainage. The trap is supplied.

The cooling and heating sections of the air handling units in

sizes 0050; 0060; 0060; 0070; 0090; 0001; 0021 are equipped

with two independent exchangers, with connection stubs

on both sides of the unit. Please consider the piping of the

exchangers also on the opposite side to the operating side.

4.8.1 Cooler and heater exchanger connections

Water heaters and coolers

Exchangers should be connected in such a way as to pre-

vent stresses that may cause mechanical damage and le-

aks. To this end we recommend appropriate compensation

of the supply and return pipeline mitigating longitudinal

expansion of the pipes. When screwing the supply and

return pipes to the exchanger stubs, use a lock key to hold

the stub pipe.

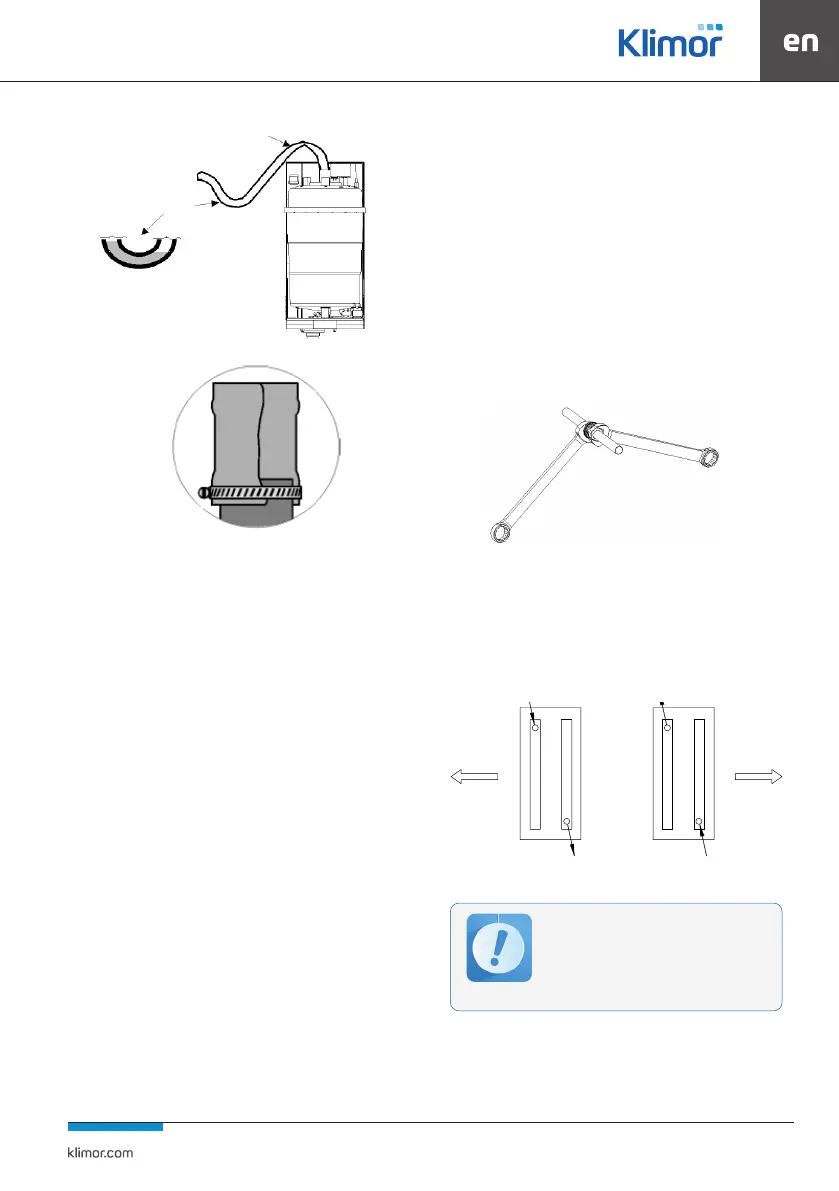

Fig. 65 Correct way of screwing the pipes

The hydraulic installation and exchanger connection should

allow their unrestrained disconnection and removal from

the unit for the purposes of repair or maintenance.

Supply and return connections are properly marked on the

service cover on AHU and their are shown on pictures.

Fig. 66 Connection of water heaters and coolers

NO

NO

Left-hand-sided version

power return

airowairow

return power

Right-hand-sided version

The connection of the water exchangers should

be carried out in a countercurrent system.

Otherwise, the average temperature dierence

between the medium in the exchanger and the

owing air will decrease, and as a result the ef-

ciency of the exchanger will decrease (for he-

aters - up to 10%, for coolers - up to 20%).

Loading...

Loading...