77

4. FUNCTIONAL UNITS

Depending on the functional requirements resulting from

the air handling process, the units are equipped with the

following batch units:

4.1 MX Mixing and recirculation

MX mixing sets are used in intake air handling units. These

sections are equipped with two dampers.

The MX recirculation sets are used in intake-outlet air han-

dling units. These sections are equipped with recirculation

damper and shut-o dampers. Dimensions of the AHU con-

nections according to Table 4.

In the PHE cross-ow exchanger section the recirculation

damper is mounted directly on the exchanger bypass chan-

nel and does not require an additional chamber.

All rectangular inlets and outlets in the units are equipped

with exible stubs. They are screwed to the damper or the

air handling unit cover. Size of exible stubs and rectangu-

lar dampers for individual units according to section 2.2.4.

Elastic connections are secured for transport by means of

metal strips. The exible connection is equipped with a yel-

low-green grounding wire, which should not be removed,

but connected to the duct system.

4.2 Air lters P, B, MP

Air lters can be supplied in accordance with PN EN 779 or

EN-ISO 16890. Filter classication is given in the Table 11.

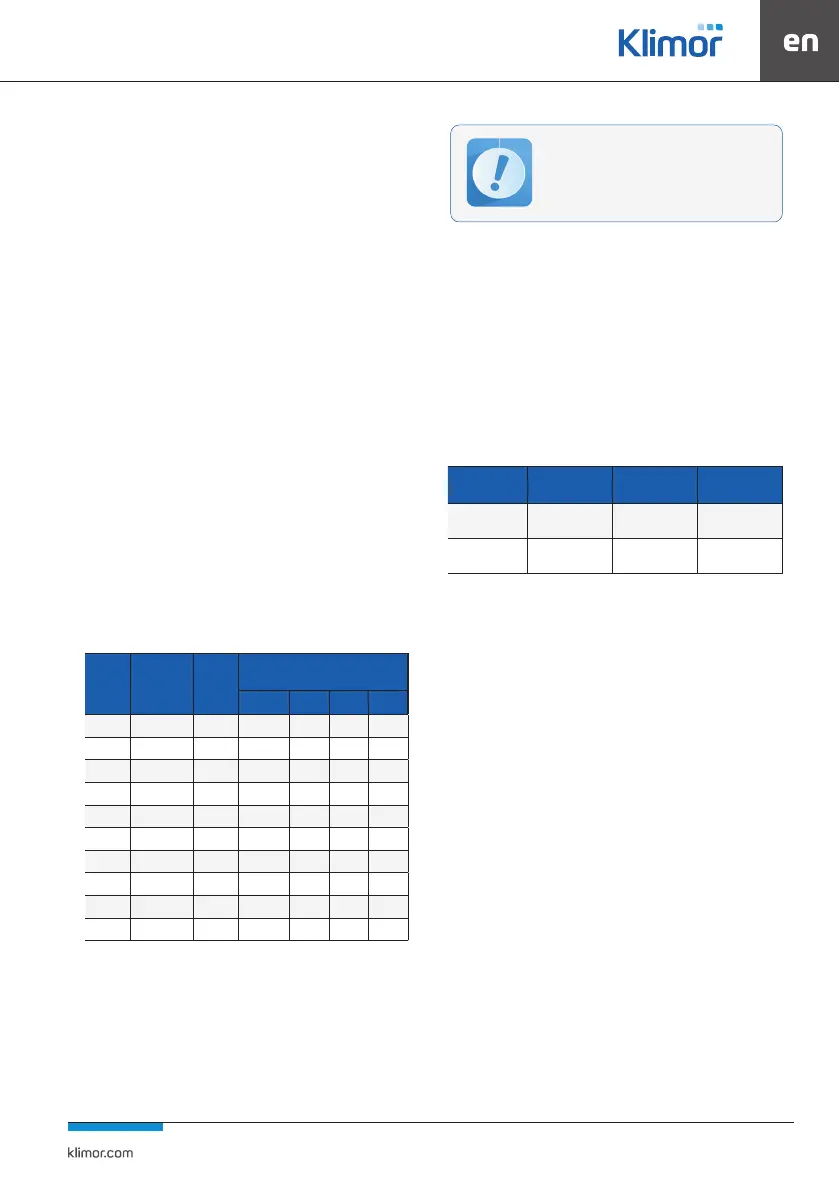

Table 11. Classication of lters used in EVO units

Filter

thickness

[mm]

Filter type

Standard

EN-779

Standard

EN ISO 16890

Filter class ePM10 ePM2,5 ePM1

48 Metal G2 Coarse 30% - - -

50 Cassette G4 Coarse 80% - - -

50 Cassette M5 ePM10 50% 50 15 5

300 Bag G4 Coarse 70% - - -

300 Bag M5 ePM10 50% 50 10 5

500 Bag F7 ePM1 55% 85 65 55

500 Bag F9 ePM1 80% 95 90 80

48 mini pleat M5 ePM10 50% 50 15 5

96 mini pleat F7 ePM1 60% 90 70 60

96 mini pleat F9 ePM1 80% 95 90 80

In the pre-ltration section PF, cassette lters class G2÷M5,

bag lters class G4 and M5 or minipleat class M5 are in-

stalled.

In the secondary ltering section SF, bag lters class F7 and

F9, minipleat class F7 and F9 or electrostatic lters are in-

stalled.

The dimensions of the lters used are specied in the KT

certicate.

The lters must be replaced when the permitted pressure

drop at the lter is exceeded (Table 12) or according to

avisual decision in the control system.

The unit must be switched o during lter renewal.

The class of new lters has to correspond to the class of the

used lters. During lter renewal also the ltration section

has to be cleaned.

Table 12 Acceptable lter pressure drop

Filter class EN 779-2012

acc. to test

ISO 16890-2018

EN 13053:2019

G1÷G4

(ISO COARSE)

250 Pa 200 Pa

+50 Pa ltra

czystego

M5÷F9

(ePM...)

450 Pa 300 Pa

+100 Pa ltra

czystego

4.2.1 Metal lter G2

G2 class metal cassette filters are filters for pre-cleaning

air from oily suspensions.

Metal filters are 48mm deep.

They are mounted in straight SR type guides in vertical or

diagonal position.

Self-adhesive seals for sealing are mounted on the walls

of the air handling unit housing at the point of filter ad-

hesion and between cassettes, if there are more filters.

Metal filters require rinsing in detergents (depending

on the type of pollution), rinsing with clean water and

drying.

4.2.2 Cassette Filter G4 and M5

G4/M5 cassette filters (panel filters) are fabric filters in

metal casing; they are designed for preliminary air treat-

ment.

Cassette filters are 50mm deep. They are mounted in

straight SR type guides.

Self-adhesive seals for sealing are mounted on the walls

of the air handling unit housing at the point of filter ad-

hesion and between cassettes, if there are more filters.

Cassette filters are not to be regenerated and must be

replaced with new ones.

The dimensions of the filters used are specified in the KT

certificate.

The factory transport safety devices sho-

uld be removed when the unit is seated at

the destination.

Loading...

Loading...