90

EVO-S, EVO-H MODULAR AIR HANDLING UNITS

OPERATION AND MAINTENANCE MANUAL

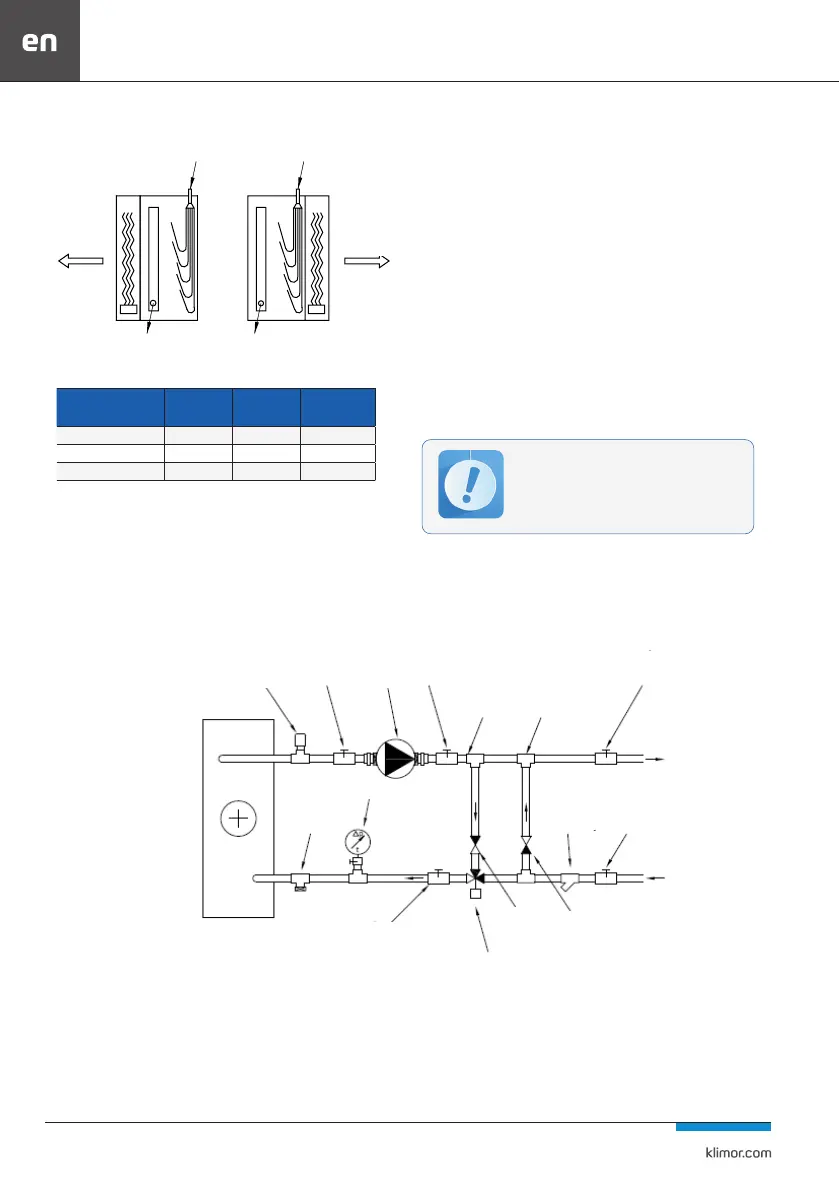

DX Cooling Coil

Fig. No. 67 Connection of DX Cooling coils

Table 18 Coil parameters

Coil

Max. work

temperature

Work pressure Test pressure

Water heater 110˚C 1,0 MPa 28 Atm

Water cooler 110˚C 1,0 MPa 28 Atm

DX cooler - 2,8 MPa 40/45 Atm

NOTE:

1. In order to protect the automatic system mechanisms aga-

inst excessive overheating, for units with heaters supplied

with medium over 100˚C, a water supply blockade should be

provided when the AHU is o (e.g. an electromagnetic valve).

2. The exchangers’ stubs should be connected in such a way

that the exchanger operates in countercurrent.

3. The diameter of the condensate tray stub pipe of the wa-

ter cooler as for the DX cooler is 32mm.

4. It is recommended to replace the drain plugs with valves

and the vent plugs with vents.

Please note that these elements are located on the exchan-

ger collectors. They can be accessed after removing the

section cover. If after installation of the exchanger supply

system access to these elements is dicult, it is necessa-

ry to lead them outside the unit in a convenient place. In

external devices, the vent and drain elements should be

protected against freezing.

5. DX coolers are lled with nitrogen at a pressure of

0.03MPa, which prevents moisture from penetrating them.

Left-hand-sided version

power power

airowairow

suction

(return)

suction

(return)

Right-hand-sided version

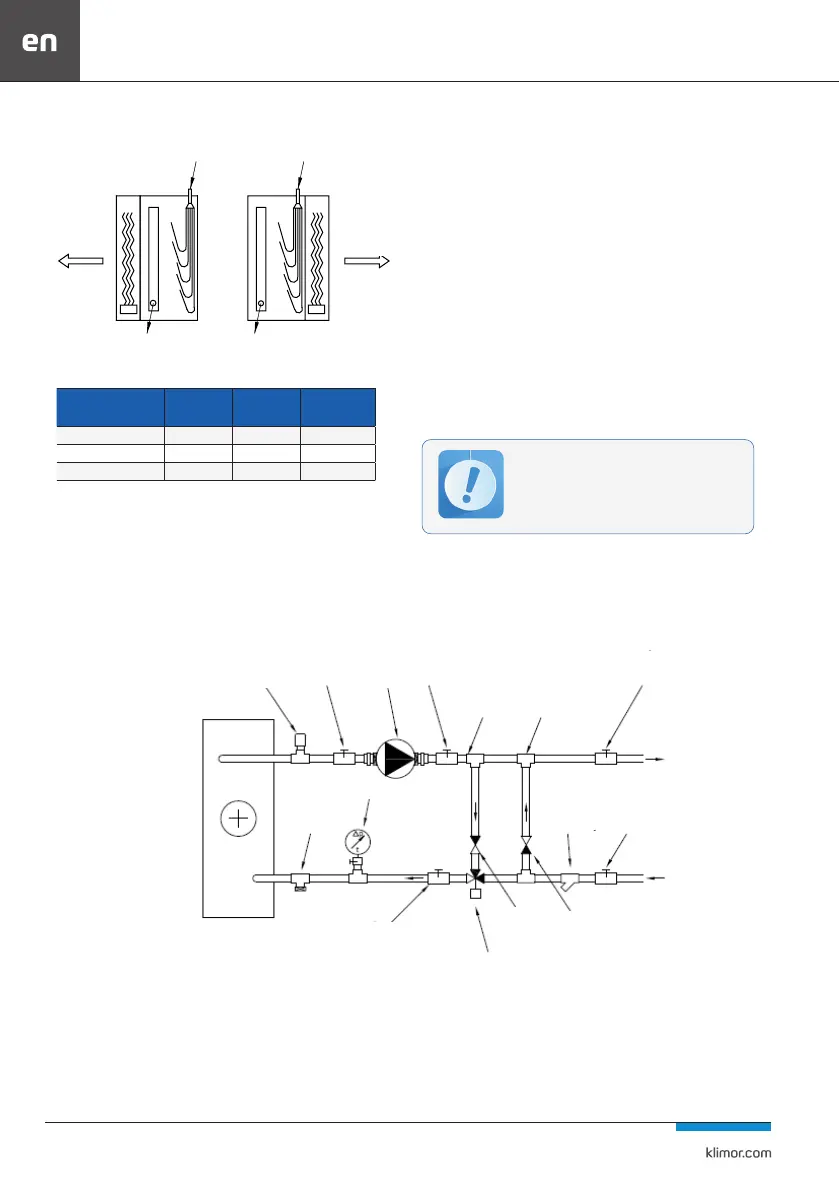

vent pump

T-piece T-piece

thermomanometer

STAD

balancing

valve

ball

valve

ball

valve

drain

valve

STAD balancing

valve (optional)

three-way

valve

check

valve

check

valve

mechanical

lter

ball

valve

When connecting the power supply to the heat

exchangers, care must be taken to ensure that

the pipes run smoothly with other installations

and with the unit housing (service access to the

unit operation).

4.8.2 Recommended heater mode design

Fig. 68 Example of connecting a water heater in a mixing system

Loading...

Loading...