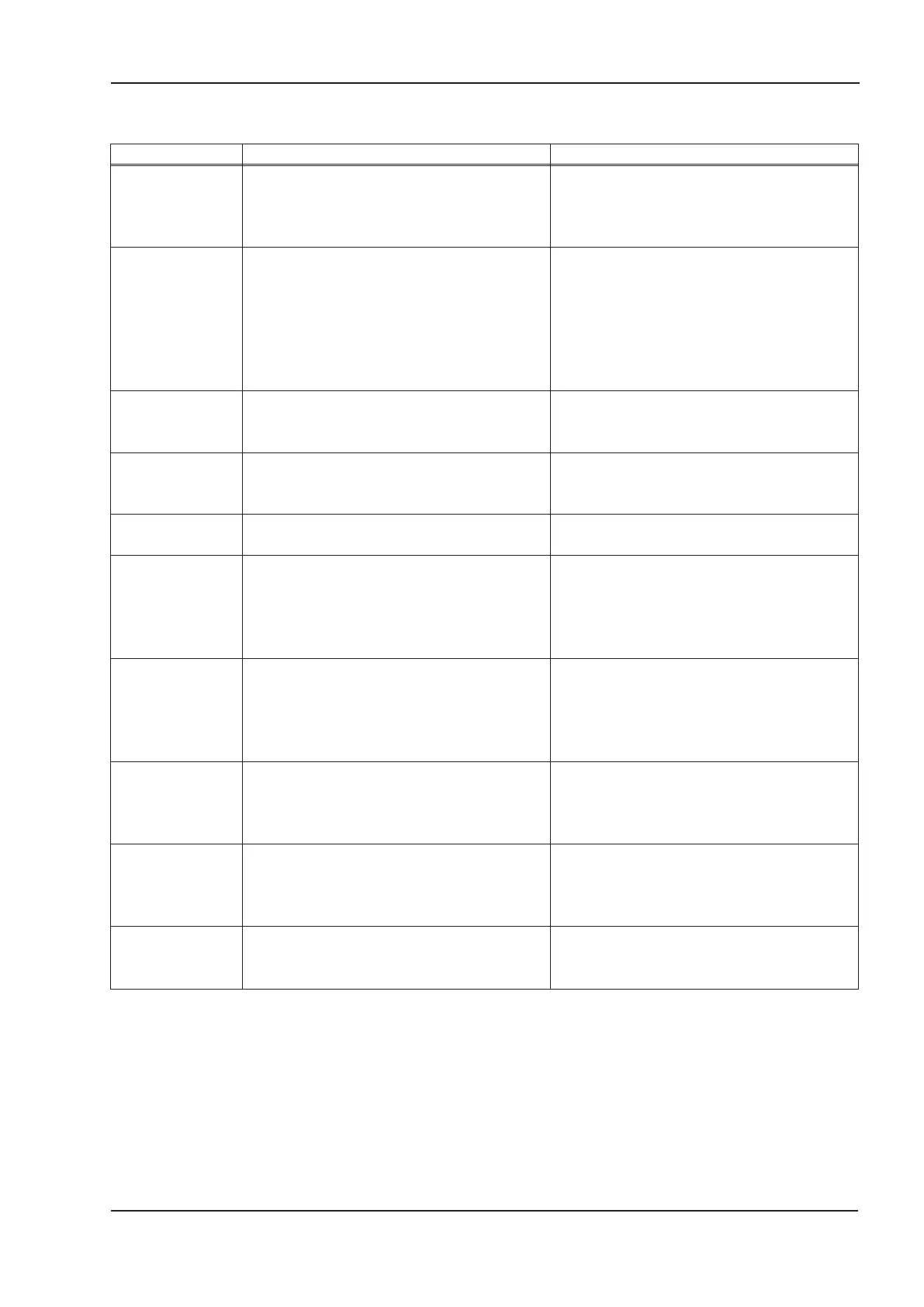

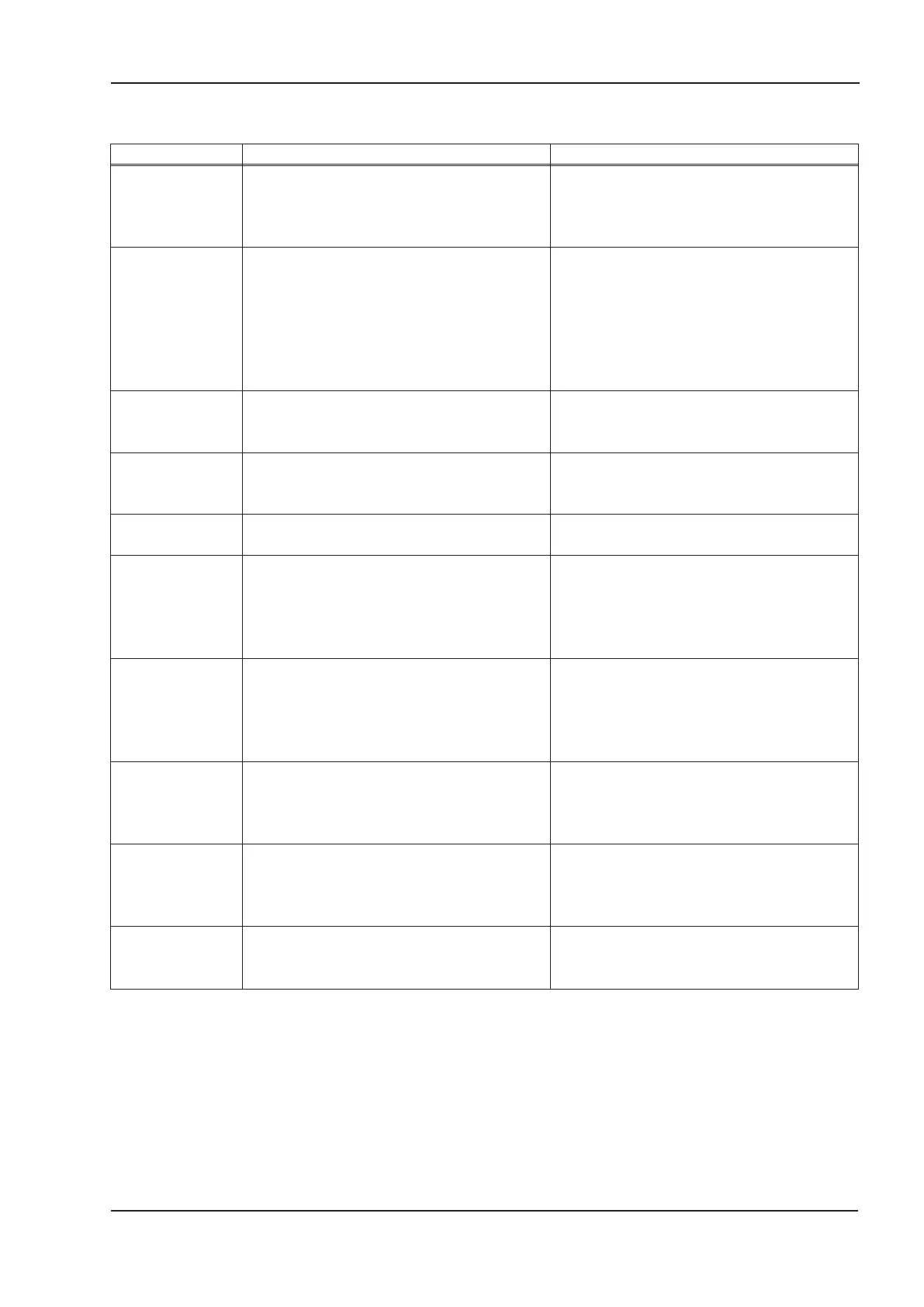

Fault possible causes Measures to remove the fault

F25 message:

Commutation er

-

ror

—

wrong cable

—

wrong phasing

—

check wiring

—

check resolver poles (RESPOLES) +

motor poles (MPOLES) + offset (MPHA

-

SE)

motor does not

rotate

—

servo amplifier not enabled

—

break in setpoint cable

—

motor phases swapped

—

brake not released

—

drive is mechanically blocked

—

no. of motor poles set incorrectly

—

feedback set up incorrectly

—

apply enable signal

—

check setpoint cable

—

correct motor phase sequence

—

check brake control

—

check mechanism

—

set no. of motor poles

—

set up feedback correctly

motor oscillates

—

gain too high (speed controller)

—

shielding in feedback cable has a break

—

AGND not wired up

—

reduce Kp (speed controller)

—

replace feedback cable

—

join AGND to CNC-GND

drive reports

following error

—

I

rms

or I

peak

is set to low

—

setpoint ramp is too long

—

increase I

rms

or I

peak

(keep within mo

-

tor data !)

—

shorten setpoint ramp +/-

motor overhea

-

ting

—

I

rms

/I

peak

set too high

—

reduce I

rms

/I

peak

drive too soft

— Kp (speed controller) too low

— Tn (speed controller) too high

— PID-T2 too high

— T-Tacho too high

— increase Kp (speed controller)

— use motor default value for Tn (speed

controller)

— reduce PID-T2

— reduce T-Tacho

drive runs

roughly

— Kp (speed controller) too high

— Tn (speed controller) too low

— PID-T2 too low

—

T-Tacho too low

— reduce Kp (speed controller)

— use motor default value for Tn (speed

controller)

— increase PID-T2

—

increase T-Tacho

axis drifts at

setpoint = 0V

—

offset not correctly adjusted for analog

setpoint provision

—

AGND not joined to the CNC-GND of

the controls

—

adjust setpoint-offset (analog I/O)

—

join AGND and CNC-GND

n12 message:

Motor default va

-

lues loaded

—

Motor number stored in sine encoders

EEPROM different than what drive is

configured for

—

If n12 is displayed, default values for the

motor are loaded. Motor number will be

automatically stored in EEPROM with

SAVE.

n14 message:

Wake & shake

active

—

Wake & shake not executed

—

Enable the drive

SERVOSTAR

®

400 Installation Manual 69

Kollmorgen 07/05 Appendix

Loading...

Loading...