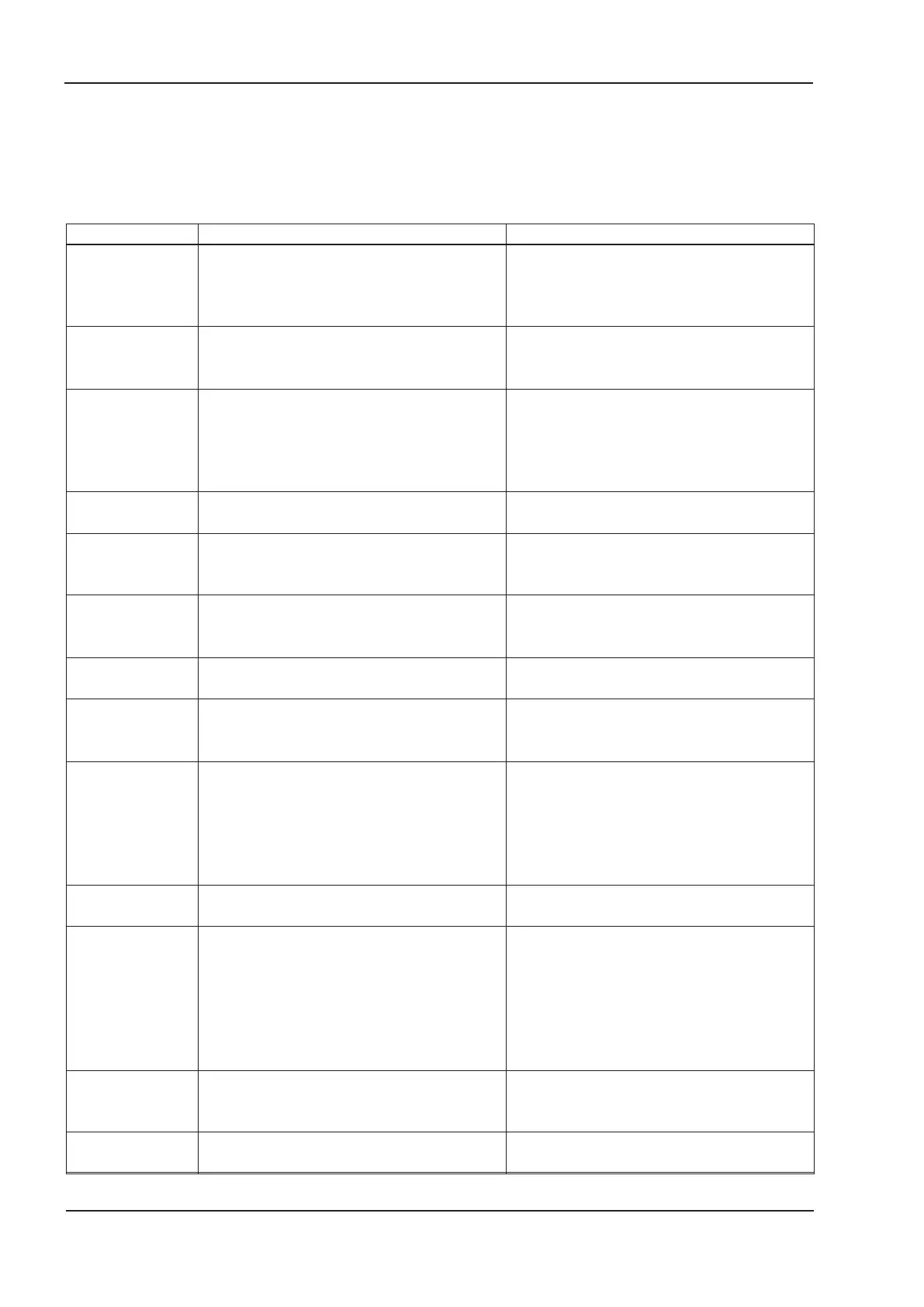

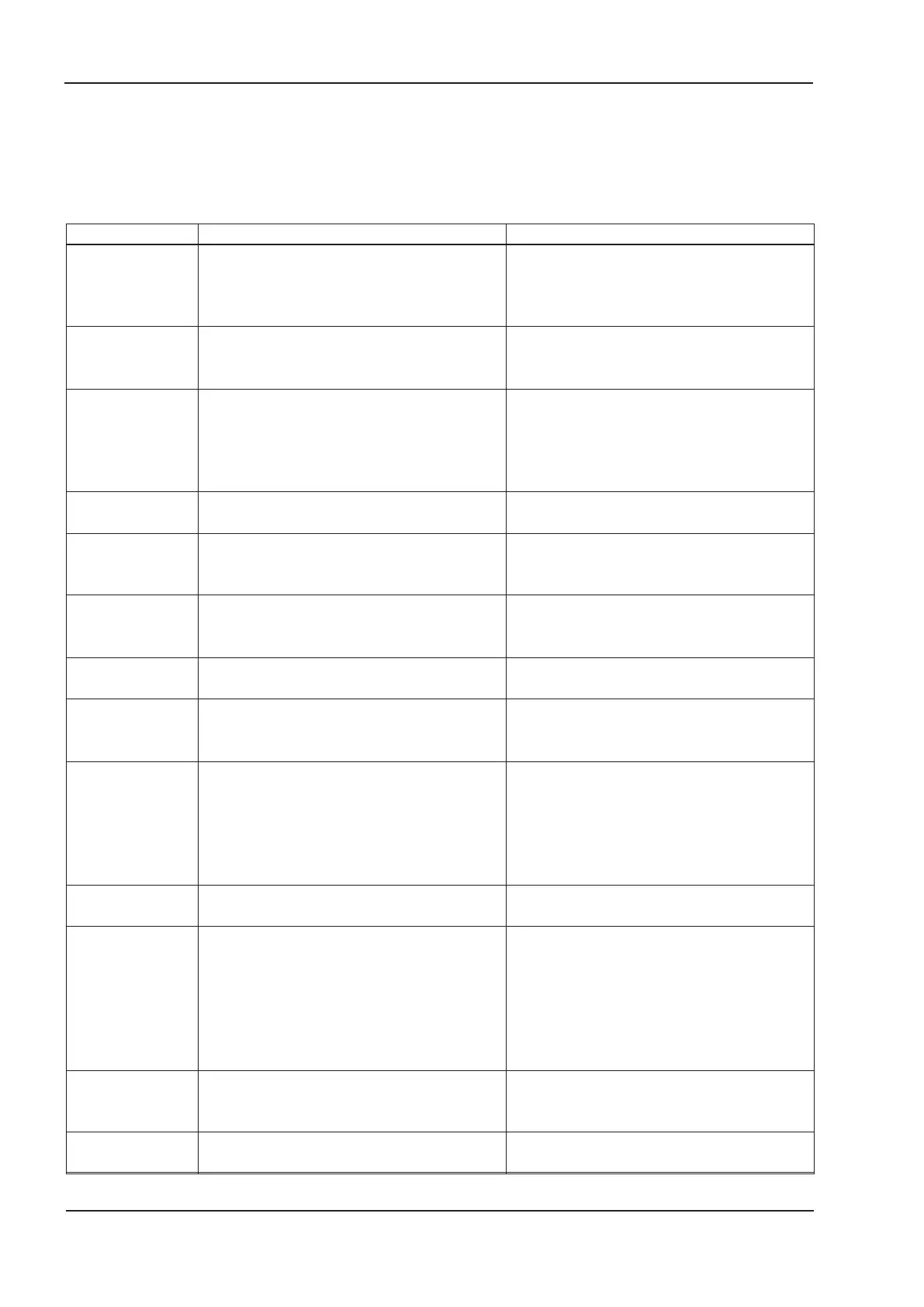

7.2 Fault-finding

The table below should be regarded as a “First-aid” box. Depending on the conditions in your installation,

there may be a wide variety of reasons for the fault. In multi-axis systems there may be further hidden cau

-

ses of a fault. Our customer support can give you further assistance with problems.

Fault possible causes Measures to remove the fault

HMI message:

communication

fault

—

wrong cable used

—

cable plugged into wrong position in

servo amplifier or PC

—

wrong PC interface selected

—

use null-modem cable

—

plug cable into the correct sockets on

the servo amplifier and PC

—

select correct interface

F01 message:

heat sink

temperature

—

permissible heat sink temperature ex

-

ceeded

—

improve ventilation

F02 message:

overvoltage

—

regen power is insufficient. regen power

limit was reached and the regen resistor

was switched off. This causes excessive

voltage in the DC Bus link circuit.

—

supply voltage too high

—

shorten the braking time RAMP or use

an external regen resistor with a higher

power rating and adjust the regen power

parameter

—

use mains transformer

F04 message:

feedback unit

—

feedback connector not inserted

—

feedback cable is damaged

—

check connector

—

check cable

F05 message:

undervoltage

—

supply voltage not present or too low

when servo amplifier is enabled

—

only enable the servo amplifier when the

mains supply voltage has been switched

on delay > 500 ms

F06 message:

motor tempera-

ture

— motor thermostat has been activated

— feedback connector is loose or break in

feedback cable

— wait until motor has cooled down, then

check why it became so hot

— tighten connector or new feedback cable

F07 message:

aux. voltage

— the aux. voltage produced by the servo

amplifier is incorrect

— return the servo amplifier to the manu-

facturer for repair

F08 message:

motor runs away

(overspeed)

— motor phases swapped

— feedback set up incorrectly

—

faulty connection to feedback unit

— correct motor phase sequence

— set up correct offset angle

—

check connector

F11 message:

brake

—

short-circuit in the supply cable for the

motor-holding brake

—

motor-holding brake is faulty

—

fault in brake cable

—

no brake connected, although the brake

parameter is set to "WITH"

—

remove short-circuit

—

replace motor

—

check shielding of brake cable

—

brake parameter set to "WITHOUT"

F13 message:

int. temperature

—

permissible internal temperature excee

-

ded

—

improve ventilation

F14 message:

output stage

fault

—

motor cable: short-circuit/ground short

—

motor has short-circuit / ground short

—

output module is overheated

—

output stage is faulty

—

short-circuit / short to ground in the ex

-

ternal regen resistor

—

replace cable

—

replace motor

—

improve ventilation

—

return the servo amplifier to the manu

-

facturer for repair

—

remove short-circuit / ground short

F16 message:

mains BTB/RTO

—

enable was applied, although the supply

voltage was not present.

—

at least 2 supply phases are missing

—

only enable the servo amplifier when the

mains supply voltage is switched on

—

check electrical supply

F17 message:

A/D converter

—

error in the analog-digital conversion,

usually caused by excessive EMI

—

reduce EMI, check screening and

grounding

68 SERVOSTAR

®

400 Installation Manual

Appendix 07/05 Kollmorgen

Loading...

Loading...