500 SERIES INSTALLATION MANUAL JULY 2016PAGE 18

Wire style and gauge shall meet requirements of local, state and

national codes.

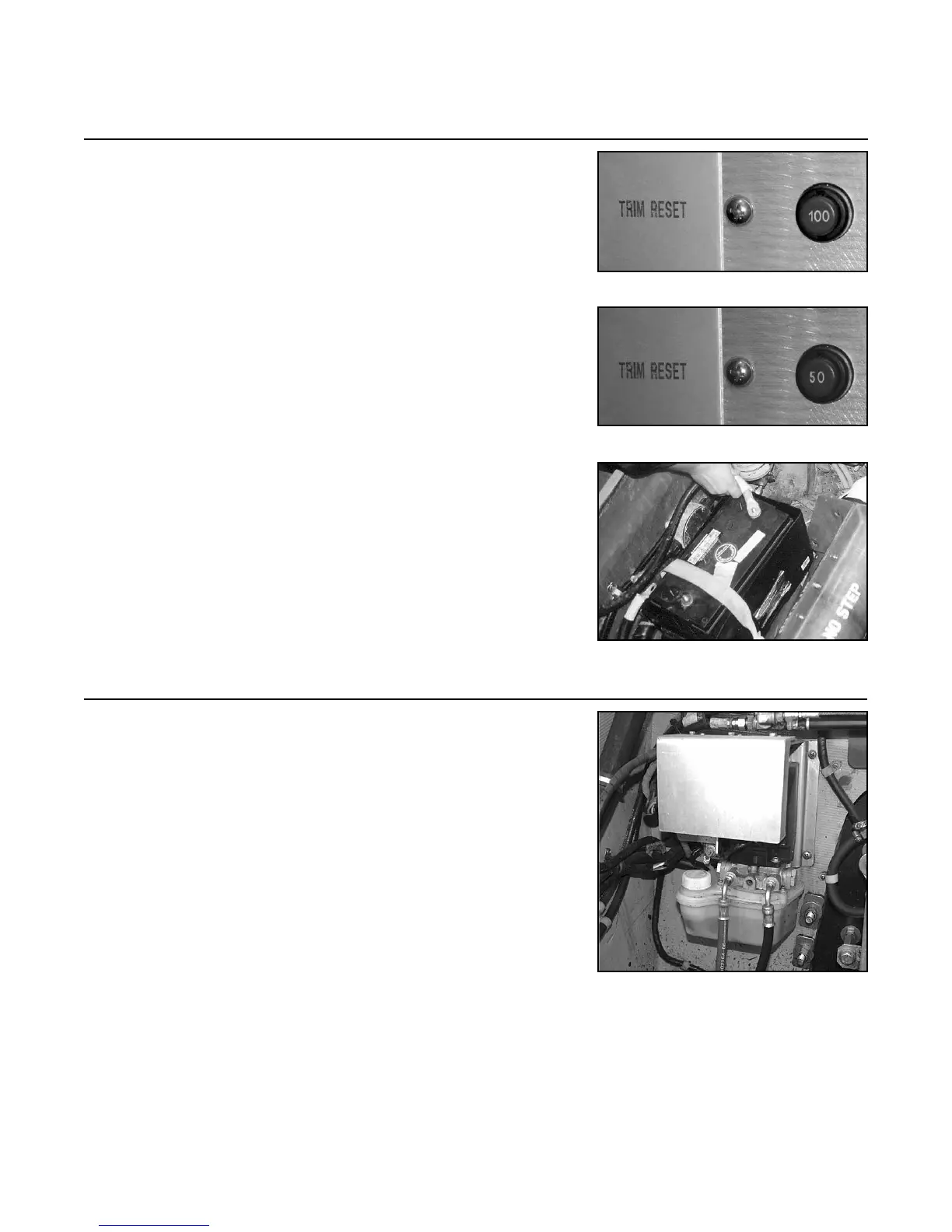

4.1 Trim pump circuit requires inline fuse/breaker (on the

positive lead) of the following values:

1) 12 Volt = 100 Amperes (see Figure 4A)

2) 24 Volt = 50 Amperes (see Figure 4B)

This item should be mounted in an accessible and logical

position away from bilge uid contact. It must also be

labeled clearly.

NOTE: Battery, or batteries, must be disconnected while

all electrical connections are being made or serviced (see

Figure 4C).

NOTE: Refer to the Trim System Electrical Drawings

(Figure C and Figure D on pages 22 and 23 in this

manual) for further documentation on this and proceeding

instructions.

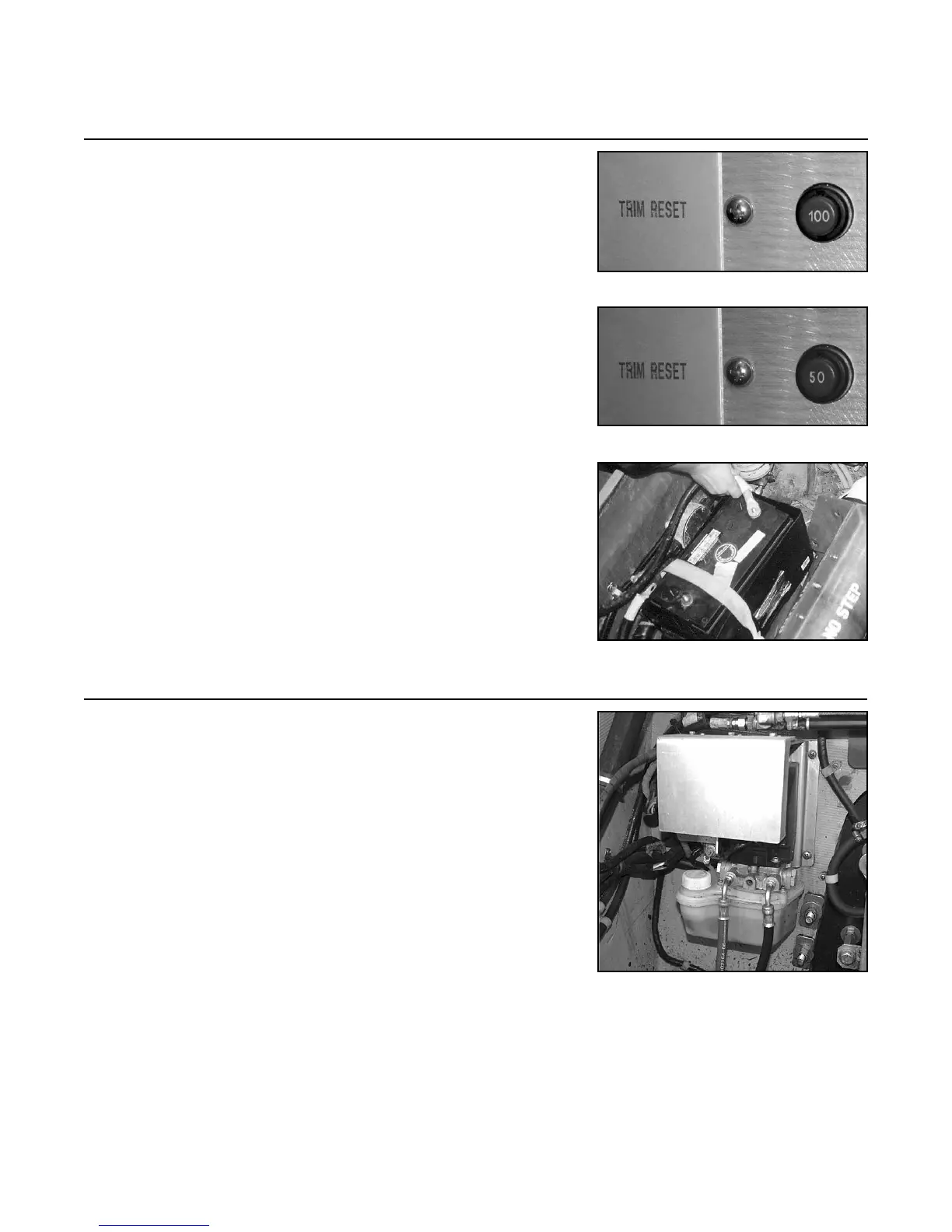

4.2 Mount trim pump in a location which is:

1) As elevated as possible and away from bilge

uid contact.

2) Is within reach of transom assembly wiring

approximately 36 in. (91.4 cm).

3) Is within reach of oil bottle wiring

approximately 48 in. (122 cm).

4) Is within reach of transom assembly hydraulic

hoses, 32 in. or 48 in. (81.3 cm or 122 cm).

Measure to determine length.

NOTE: For berglass hulls, it is recommended that a

pilot hole be drilled prior to lag screw installation.

NOTE: For metal hulls, attach by either welding or us-

ing a mounting plate.

NOTE: The two (2) hydraulic hoses in this photo will be

attached in later steps.

Step 4: Trim/Lift Pump Installation

FIGURE 4A

FIGURE 4D

FIGURE 4B

FIGURE 4C

Loading...

Loading...