TECHNICAL DATA 2

13

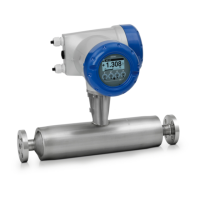

OPTISONIC 6300

www.krohne.com09/2020 - 4006413102 - TD OPTISONIC 6300 V2 R02 en

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

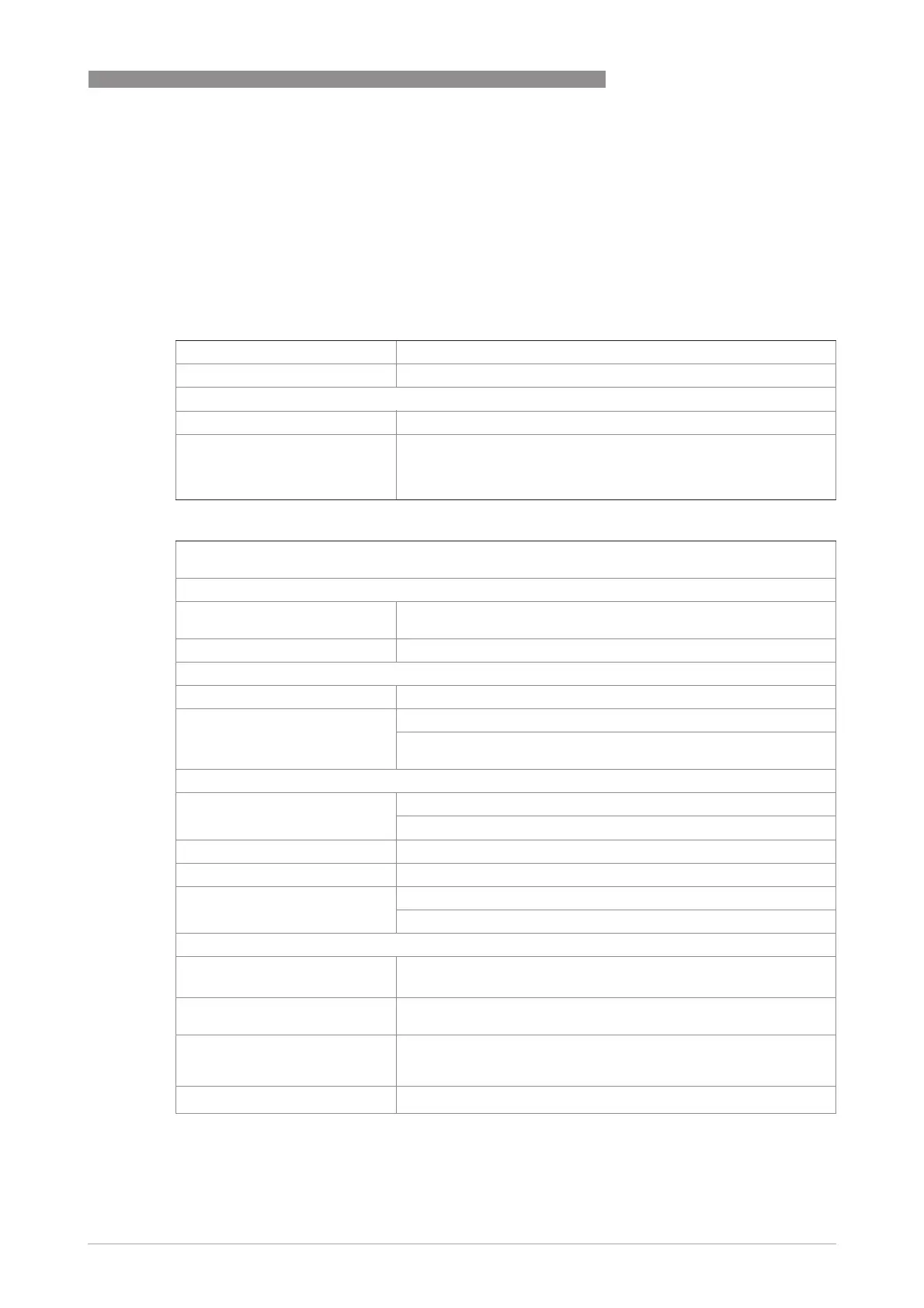

Measuring system

Measuring principle Ultrasonic transit time

Application range Flow measurement of liquids

Measured value

Measured valueMeasured value

Measured value

Primary measured value Transit time

Secondary measured value Volume flow, mass flow, flow speed, flow direction, speed of sound,

gain, signal to noise ratio, diagnosis value, reliability of flow

measurement, quality of the acoustic signal.

Optional: thermal power, thermal energy, temperature.

Design

The measurement system consists of a measuring sensor rail and a signal converter. It is only available

as a separate (remote) version.

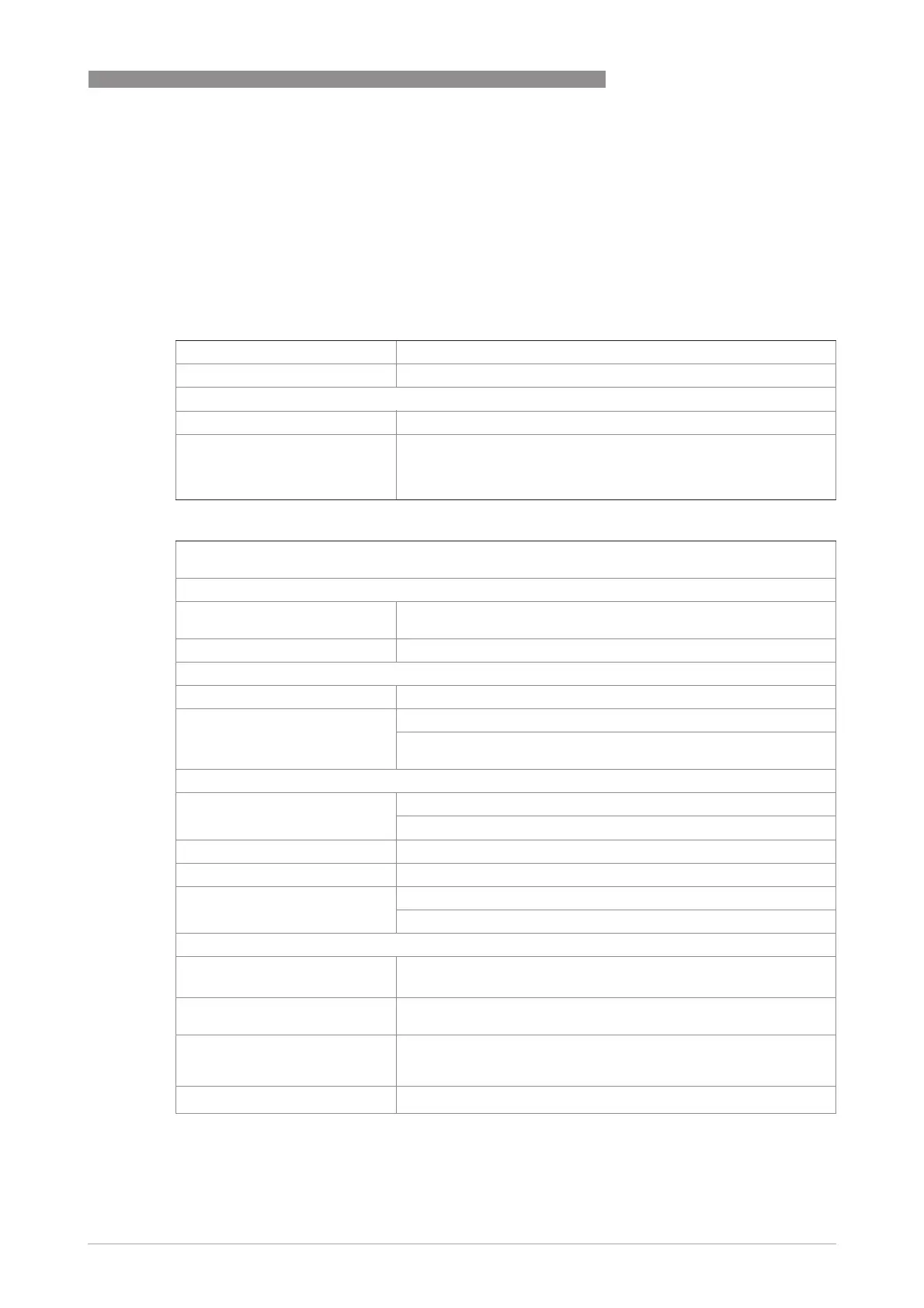

Signal converter

Signal converterSignal converter

Signal converter

Wall-mounted housing (W);

remote version

UFC 300 W (general purpose)

Field housing (F); remote version UFC 300 F (option: Ex version)

Sensor rail(s)

Sensor rail(s)Sensor rail(s)

Sensor rail(s)

Standard Small, medium or large stainless steel version

Optional Medium rail for X mode

All sensor rail(s) (small, medium and large) are available in XT

version (eXtended Temperature), Offshore version

Diameter ranges

Diameter rangesDiameter ranges

Diameter ranges

Small DN15...100 / ½…4"

Outer diameter must be at least 20 mm / 0.79"

Medium DN50...400 / 2...16"

Medium X - mode DN200...1250 / 8...50"

Large DN200...4000 / 8…160"

Outer diameter must be smaller than 4300 mm / 169.29"

Signal converter

Signal converterSignal converter

Signal converter

Inputs/outputs

Current (incl. HART

®

), pulse, frequency and/or status output, limit

switch and/or control input (depending on the I/O version).

Counters Two internal counters with a maximum of 8 counter places (e.g. for

counting volume and/or mass units).

Verification and self-diagnostics Integrated verification, diagnostic functions: measuring device,

process, measured values, device configuration, empty pipe

detection, bar graph etc.

Communication interfaces

HART

®

7, Foundation Fieldbus, Profibus, Modbus RS485 (option).

Loading...

Loading...