LOADING AND SECURING

160

Operating instructions • Semitrailer • 505369471-04 • 02/2019

Use chains to lash coils that are at risk

of tipping and coils with an external dia-

meter 2.1m or greater

NOTE

Material damage due to overloaded

chains!

When lashing down coils with a large dia-

meter, there is a higher load on the lash-

ing chain that is wrapped twice around the

upper half of the coil. If overloaded, the

chain may break resulting in accidents

with material damage.

► Use lashing chains with a sufficient

load capacity.

► Avoid using chains that are too weak

and break.

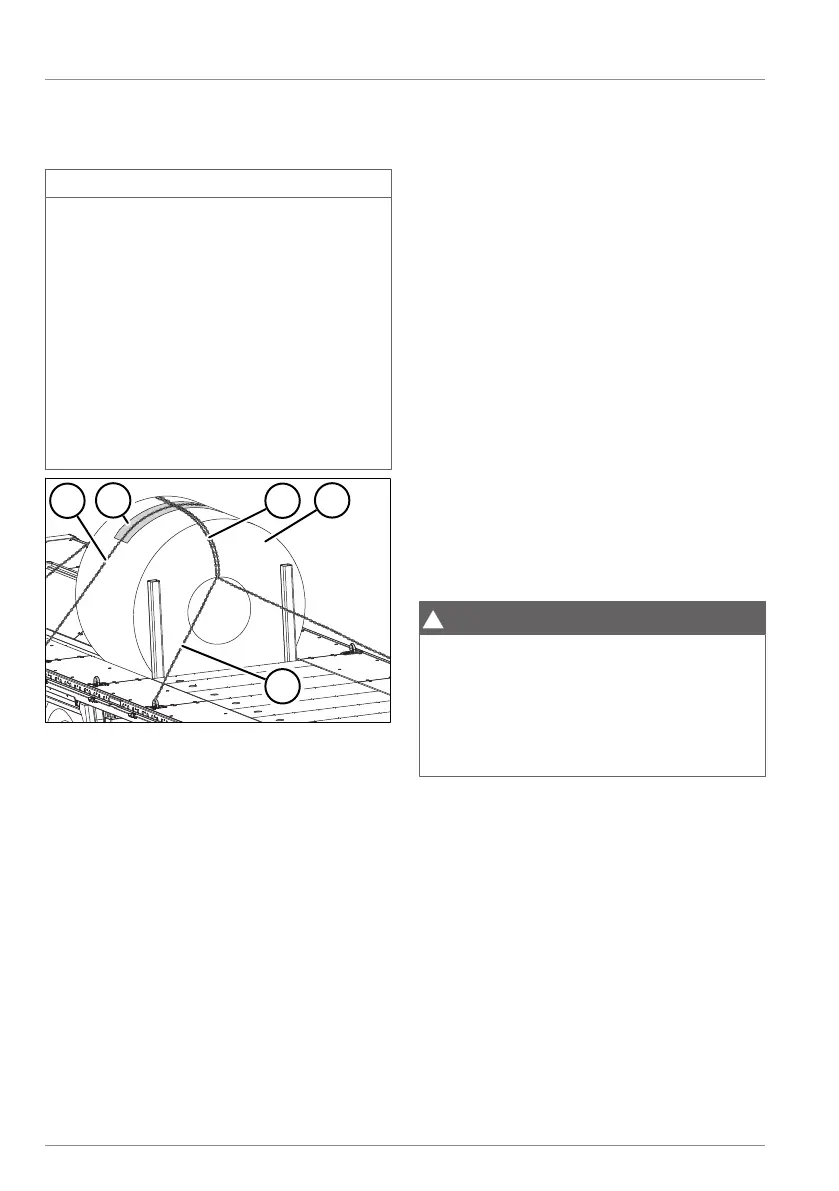

Fig.8-63: Using chains to lash coils that are

at risk of tipping

1 Lashing down the coil transversely

2 Spacer

3 Chain wrapped twice around the coil

4 Coil

5 Chain lashed diagonally

► To protect the load, position a suitable

underlay material under the chain.

► Lash down the coil across the direction

of travel.

► Guide a chain through the opening of

the coil. Select a highly resilient chain.

► Pass the chain around the upper coil

half twice.

► Hook the chains to each other.

► Guide the chains through the doubled

chains on the rear of the coil and then

tension the chains accordingly.

► Lash down the chain to the lashing

eyelets diagonally.

ü The coil is lashed down with chains.

Lashing down coils with tension straps

Lashing down the coils with tension straps

is done in the same way as lashing down

with chains.

8.12.3 Vario Coil system

WARNING

Serious injuries caused by slipping of

the load!

The load is not fully secured with the Vario

Coil system.

► Other suitable measures for load se-

curing are absolutely essential.

Loading...

Loading...