LOADING AND SECURING

Operating instructions • Semitrailer • 505369471-04 • 02/2019

147

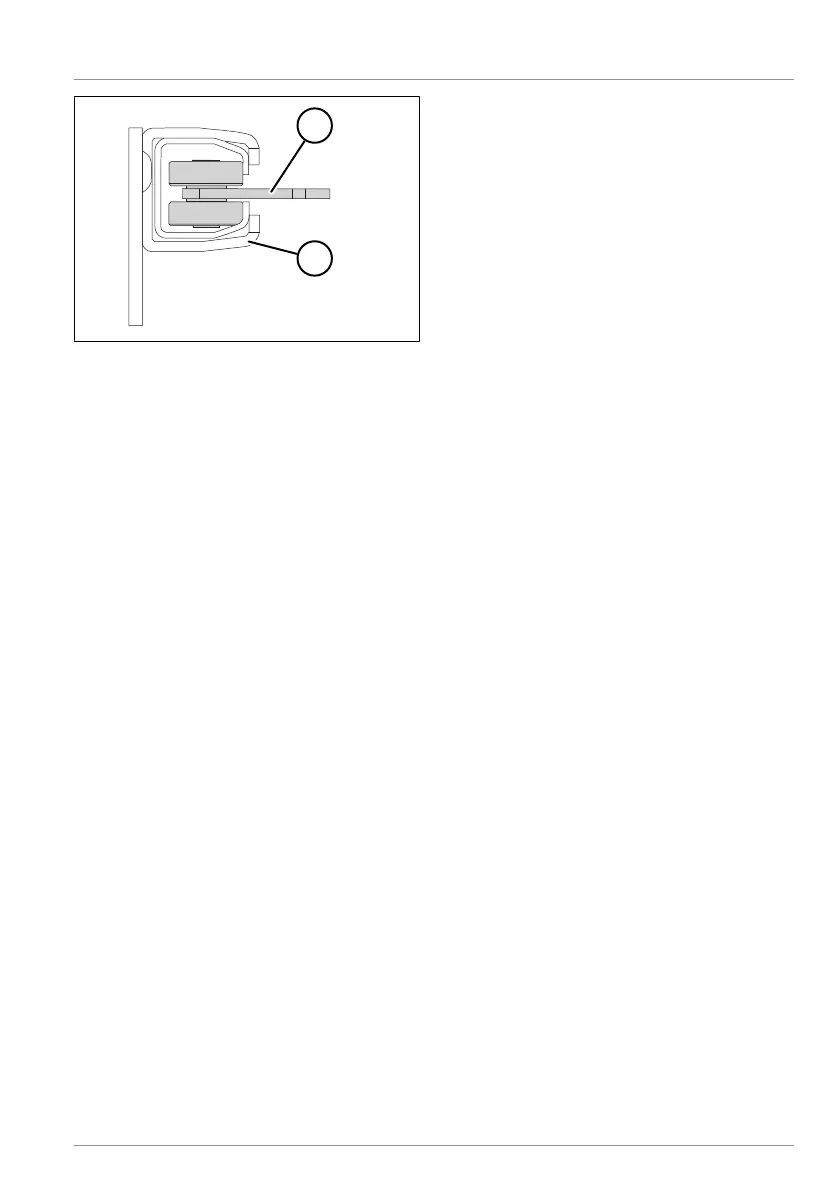

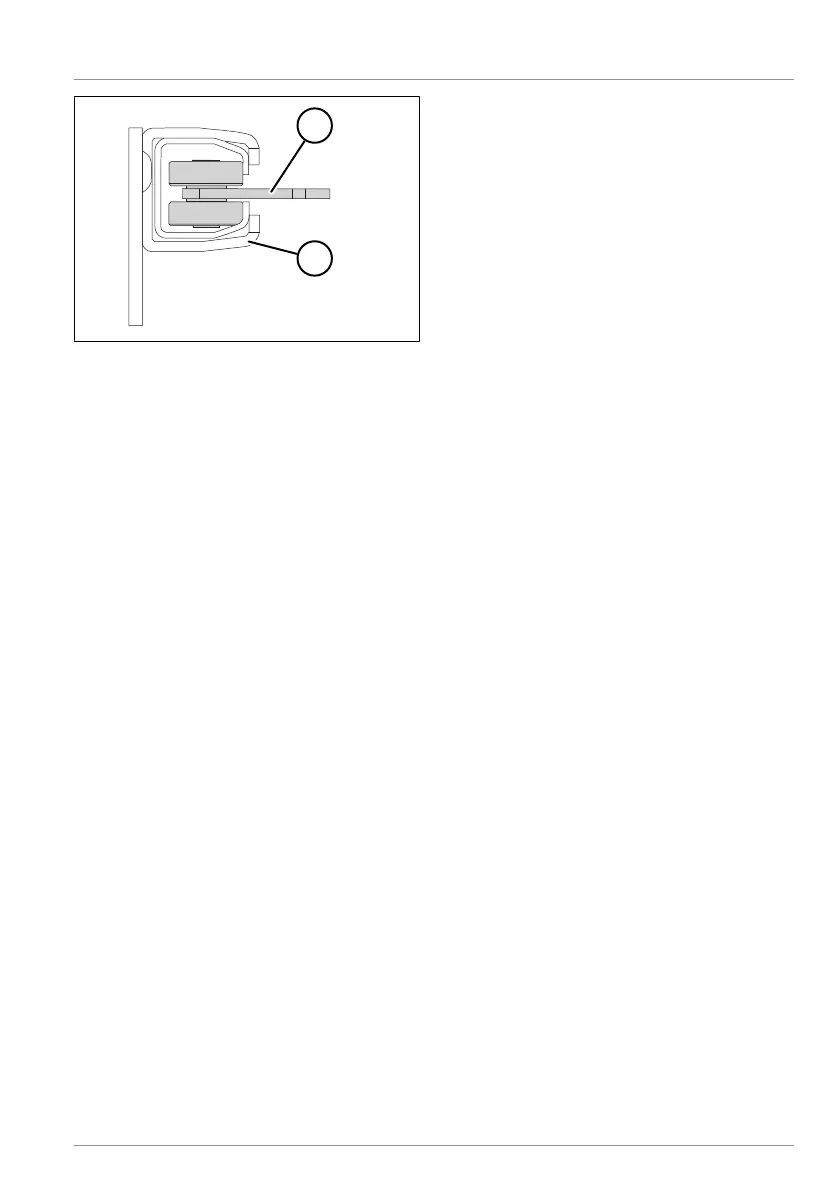

Fig.8-28: Multi Strap sliding rail with bogie

truck

1 Multi Strap bogie truck

2 Multi Strap sliding rail

The tension straps held by the bogie truck

are pulled to the required position by a

traction device. The position and number of

belt lifting units depends on the position

and number of lashing eyelets on the trailer

floor. Unneeded tension straps are at-

tached to the front wall in the parking posi-

tion.

Performing a functional check

► Attach the load securing tension straps

to the corresponding lashing eyelets

on the trailer.

► Tighten the tension straps with the

ratchet until the Multi Strap system has

stretched.

► Fully release the Multi Strap system

again.

ü The Multi Strap system pulls the inser-

ted tension straps back into the

standby position below the roof of the

trailer.

ü The functional check has been per-

formed.

Tensioning the Multi Strap system

þ The tension straps are located above

the load to be secured.

► Pull down the tension straps and

thread them into the ratchet elements.

ð The Multi Strap system is

stretched.

► Attach the ratchet elements to the

lashing eyelets on the trailer.

► Lash the tension straps according to

the load.

► Tighten the tension straps with the

ratchet.

ü The Multi Strap system is tensioned.

Releasing the Multi Strap system

► Release the tension straps with the

ratchet.

ð The Multi Strap system pulls the

inserted tension straps back into

the standby position below the

roof of the trailer.

► Slowly guide the tension straps back

upwards.

ü The Multi Strap system is released.

8.9.10 Using the Multi Tyre system

KRONE Mega Liners can be equipped with

the Multi Tyre load securing system for

tyres.

The Multi Tyre system consists of a

double-walled side curtain, each with five

vertical aluminium profiles integrated in the

four lateral post fields.

Each side has two special cables fitted

over the entire length of the vehicle. The

cables are tensioned with hydraulic hand

pumps. If there is a partial load, the cargo

area must be secured in the vehicle's lon-

gitudinal direction by tensioning crosswise.

The load volume is 100m³. The floor is de-

signed for forklift axle loads of up to

7,000kg.

Loading...

Loading...