10. CRANKCASE/CRANKSHAFT

10-2

SUPER8 50 2T

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• This section covers crankcase separation to service the crankshaft.

• The following parts must be removed before separating the crankcase.

Engine (

Ö

Section 5) Driven pulley (

Ö

Section 9)

Carburetor (

Ö

Section 11) A.C. generator (

Ö

Section 7)

Oil pump (

Ö

Section 4) Cylinder head/cylinder (

Ö

Section 6)

Reed valve (

Ö

Section 11)

• When the left crankcase must be replaced, remove the following part in addition to the above.

Final reduction removal

• Special tools must be used for crankshaft and crankcase assembly. When separating the

crankcase, the bearing will remain in the crankcase and it should be removed. When, assembling,

drive a new bearing into the crankcase and install a new oil seal.

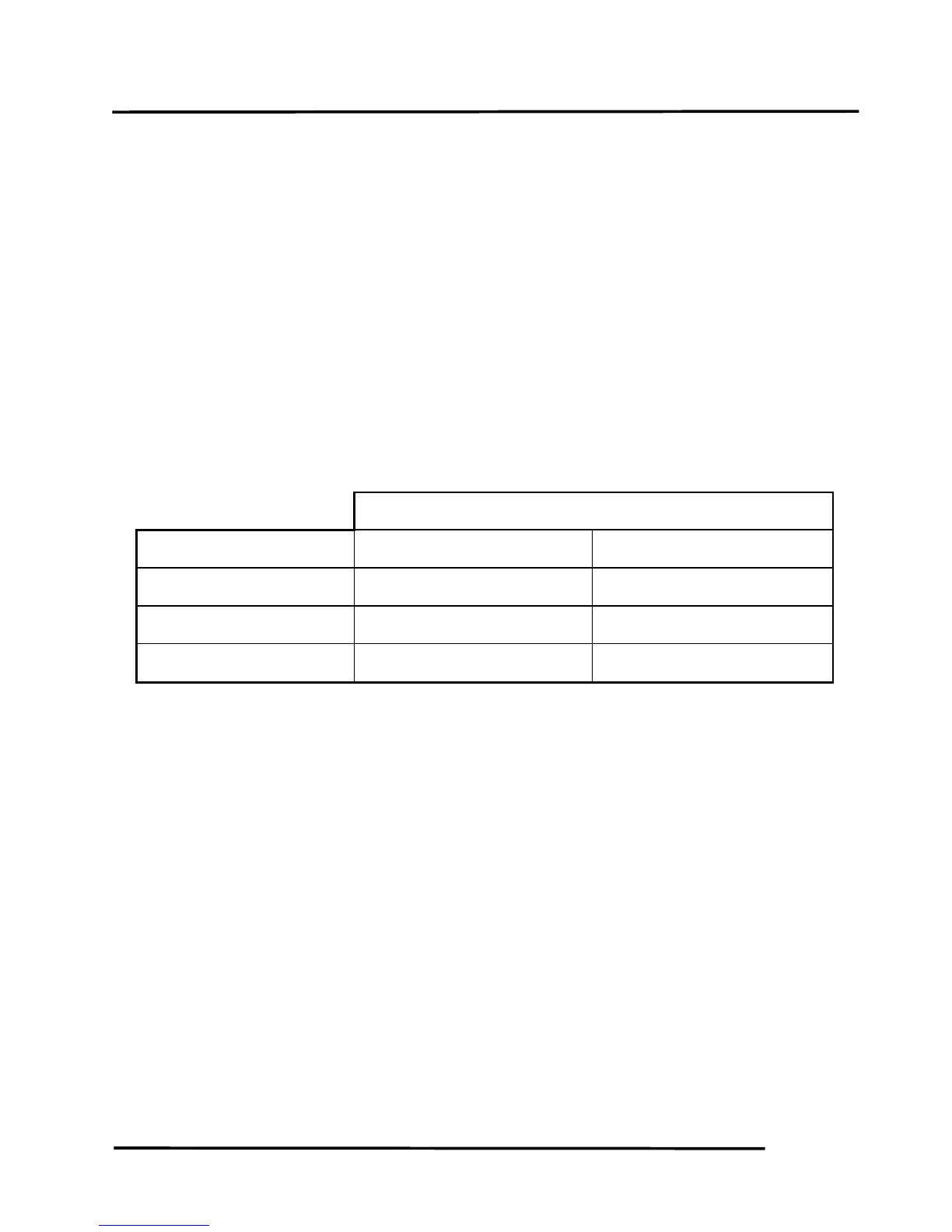

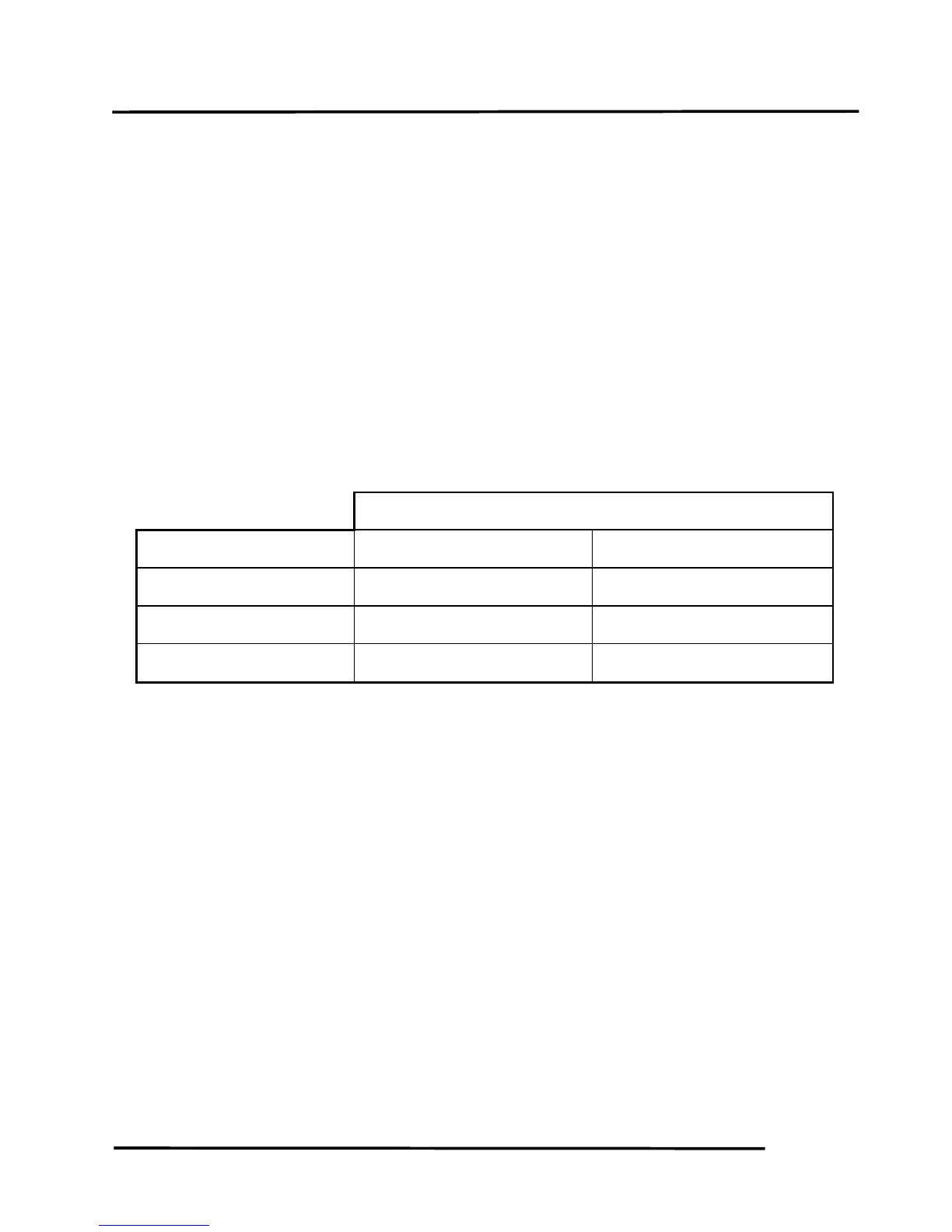

SPECIFICATIONS

SUPER8 50 2T

Item

Standard (mm) Service Limit (mm)

Connecting rod big end side

clearance

⎯ 0.60

Connectin

end radial

clearance

⎯ 0.04

Crankshaft runout A/B

⎯ 0.15/0.10

SPECIAL TOOLS

Crankcase puller Bearing outer driver handle A

Universal bearing puller Bearing outer driver, 42x47mm

Crankcase assembly collar Bearing driver pilot, 20mm

Crankcase assembly tool Bearing outer driver, 37x40mm

Bearing driver pilot, 17mm

TROUBLESHOOTING

Abnormal engine noise

• Excessive crank journal bearing play

• Excessive crankpin bearing play

• Excessive transmission bearing play

Loading...

Loading...