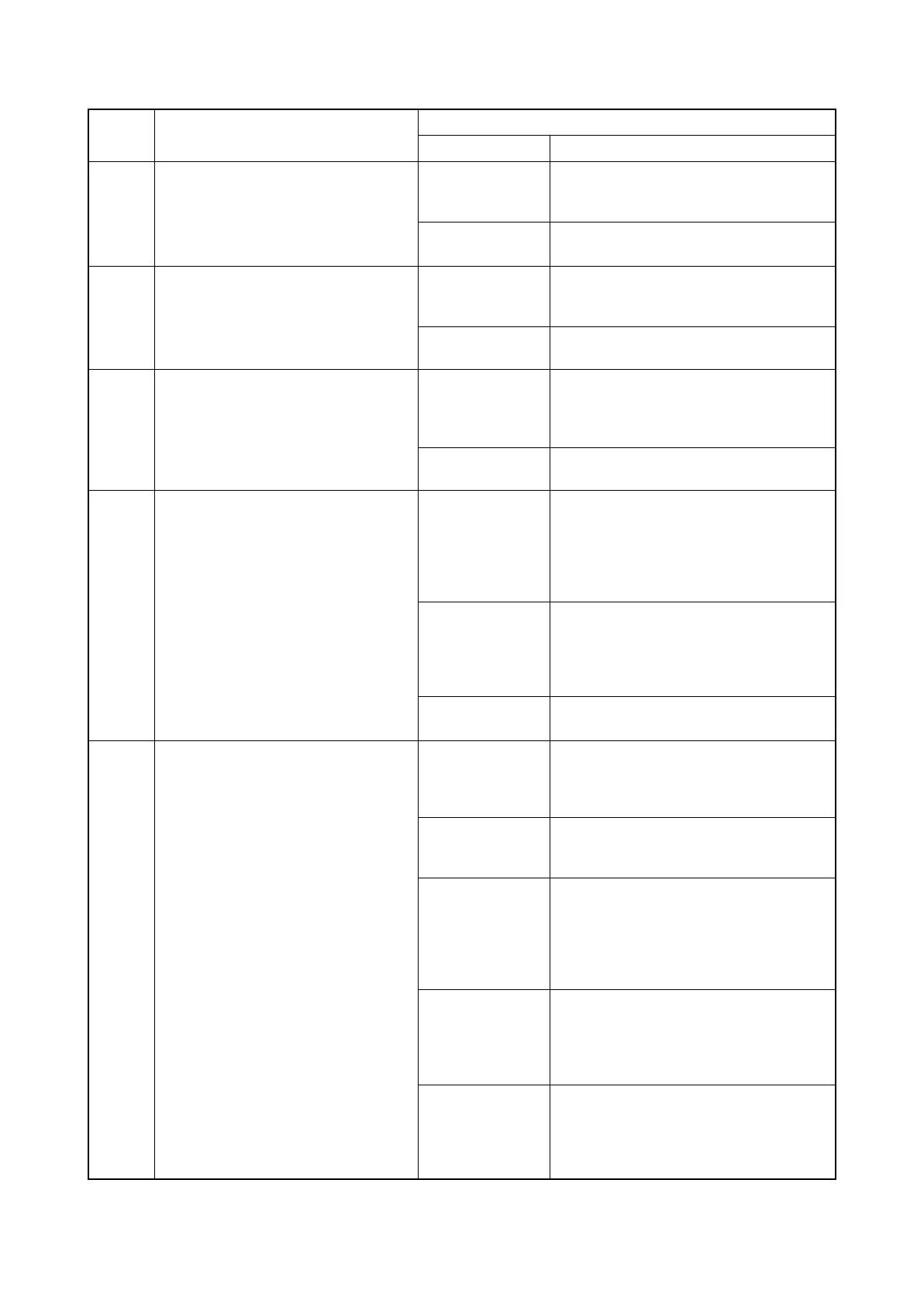

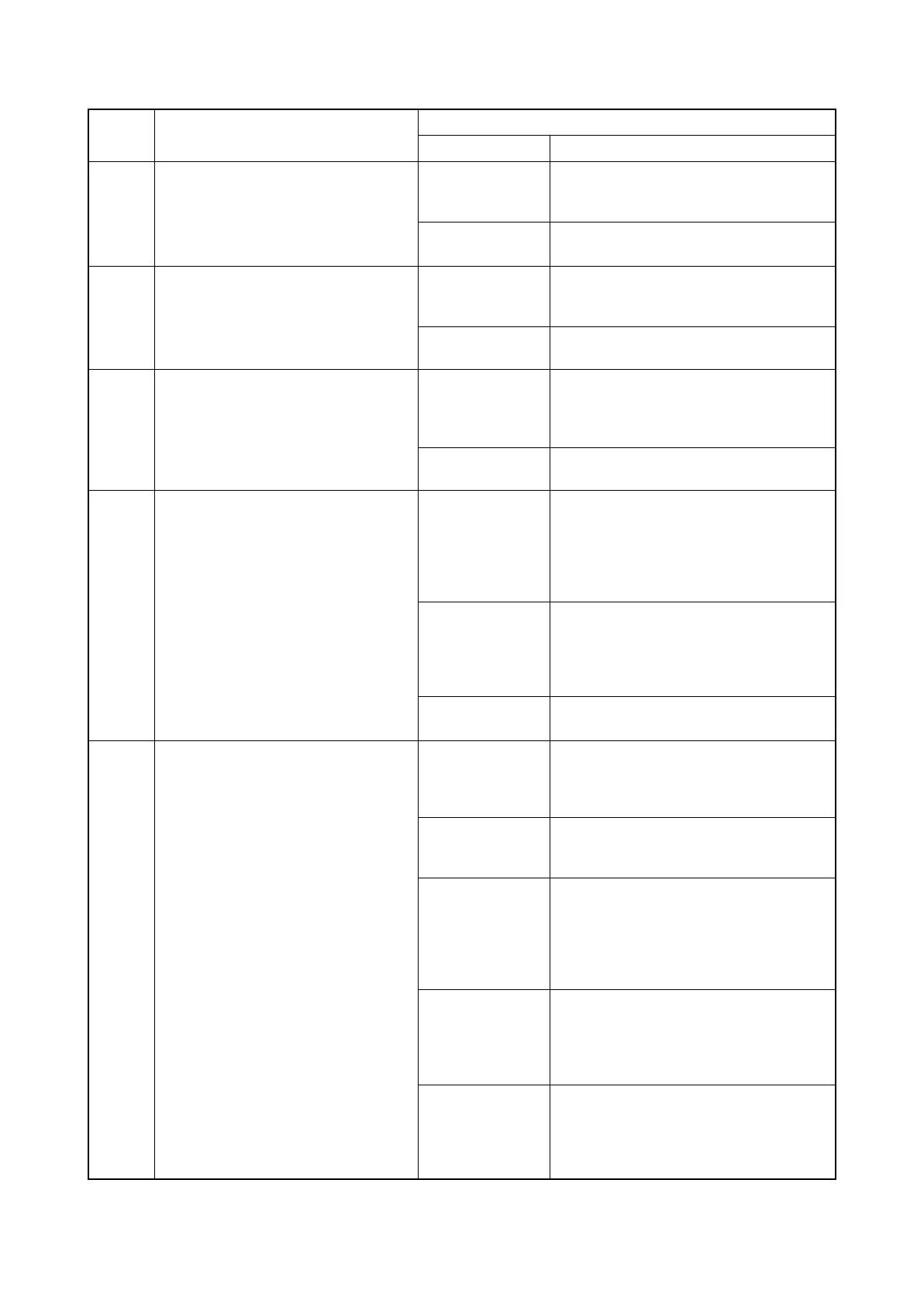

2H0/2HZ-1

1-4-27

C7400 Developing unit connector insertion

problem

Absence of the developing unit is

detected.

Developing unit

connector inserted

incorrectly.

Reinsert the developing unit connector if

necessary.

Defective develop-

ing unit connector.

Replace the developing unit.

C7410 Drum unit connector insertion prob-

lem

Absence of the drum unit is detected.

Drum unit connec-

tor inserted incor-

rectly.

Reinsert the drum unit connector if neces-

sary.

Defective drum unit

connector.

Replace the drum unit.

C7800 Broken external thermistor wire

The thermistor output value is 4.5 V or

more.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC1 on

the engine PWB and the continuity across

the connector terminals. Repair or replace if

necessary.

Defective humidity

sensor.

Replace the humidity sensor.

C8030 Tray upper limit detection problem

(optional document finisher)

When the tray elevation motor raises a

tray, the ON status of the tray upper limit

sensor is detected.

The tray upper limit

sensor/push paper

sensor/surface

view sensor con-

nector makes poor

contact.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

remedy or replace the cable.

Defective tray

upper limit sensor/

push paper sensor/

surface view sen-

sor.

Replace the sensor.

Defective finisher

main PWB.

Replace the finisher main PWB and check

for correct operation.

C8140 Tray elevation motor problem

(optional document finisher)

When the tray elevation motor is driving,

the ON status of the tray lower limit sen-

sor or surface view sensor cannot be

detected even if 10 s passed.

The tray elevation

motor connector

makes poor con-

tact.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

remedy or replace the cable.

The tray elevation

motor malfunc-

tions.

Replace the tray elevation motor.

The tray lower limit

sensor/push paper

sensor/surface

view sensor con-

nector makes poor

contact.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

remedy or replace the cable.

Defective tray

lower limit sensor/

push paper sensor/

surface view sen-

sor.

Replace the sensor.

Defective finisher

main PWB.

Replace the finisher main PWB and check

for correct operation.

Code Contents

Remarks

Causes Check procedures/corrective measures

Loading...

Loading...