92 CHAPTER 3

Maintenance

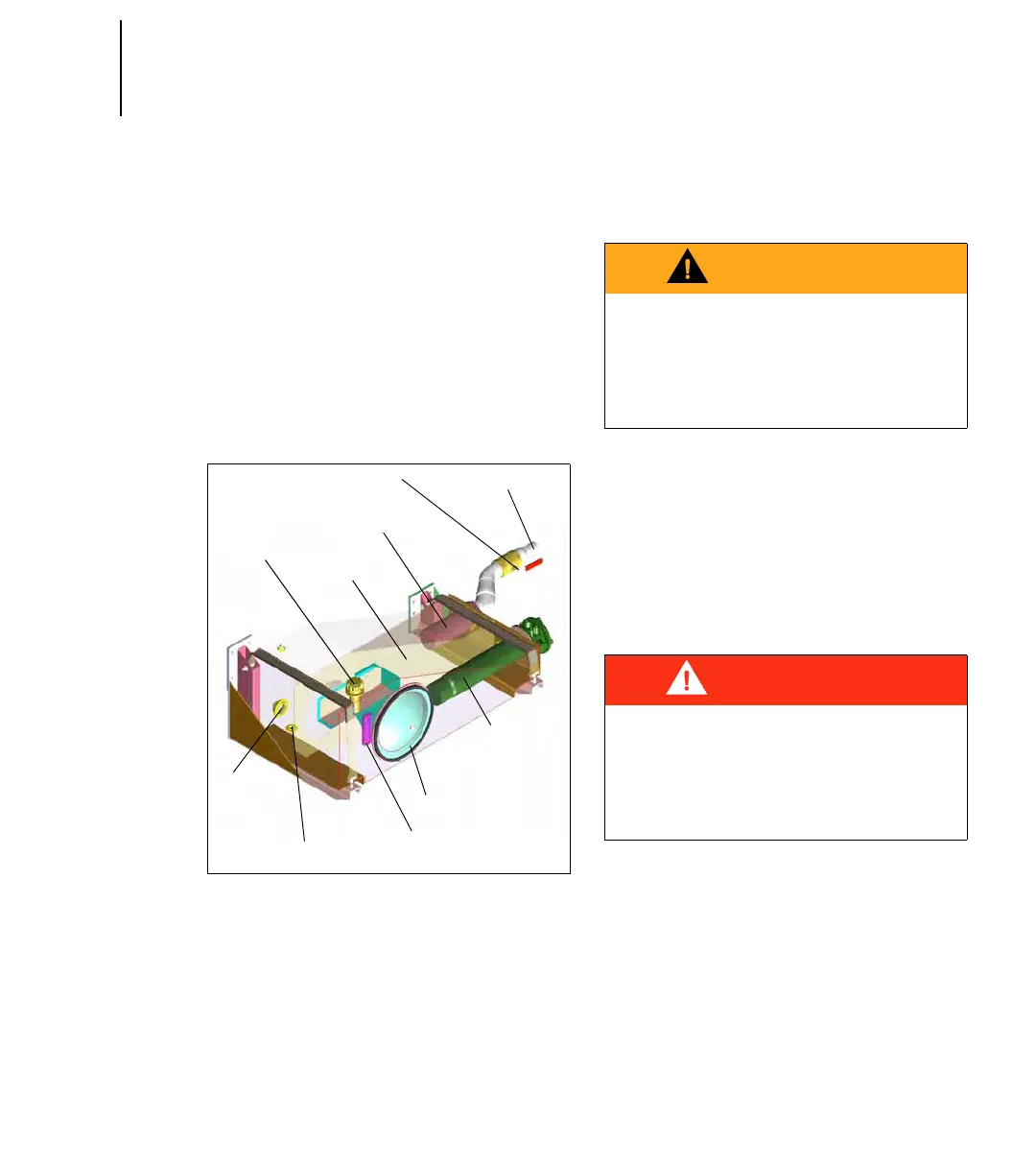

4. Ensure the proper operation of

the filler cap (Figure 144.

“Hydraulic Tank”). Make sure the

filler cap has no obstruction;

5. The hydraulic oil must be clean

and not colored as well as in

sufficient quantity (level at ¾ of

the oil level gauge, with all

cylinders retracted);

Note:The whole system requires

50 to 60 gallons of oil.

Figure 144. Hydraulic Tank

Hydraulic Oil

Replacement Procedure

To change the hydraulic oil, apply

the following procedure:

1. Make sure the parking brake is

applied and the vehicle is tagged

out for maintenance purposes

(refer to “Lockout/Tagout

Procedure” on page 8);

2. Start the engine;

3. Engage the hydraulic pump;

4. Disable the speed-up system;

5. Retract all cylinders (Packer,

crusher panel, tailgate etc.);

Suction Line

Ball Valve

Strainer

Baffle

Filler/

Breather Cap

Oil Heater

Plug

Drain Plug

Oil Temp/Level Gauge

Access Cover

Filter

Element

Housing

WARNING

HIGHLY CONTAMINATED HYDRAULIC

FLUID

MUST BE CHANGED PROMPTLY TO

AVOID

ANY DAMAGE ON THE HYDRAULIC

SYSTEM

.

DANGER

APPLY THE LOCKOUT / TAGOUT

PROCEDURE

AT ALL TIMES WHEN

MAINTENANCE

OR INSPECTION IS

CARRIED

OUT ON THE VEHICLE.

Loading...

Loading...