4. OPERATION

33

4-6. SLIDING TABLE

The sliding table is moved on high precision sideways which is made of hardened

steel for a uniform and smooth motion with less friction and obtain accurate cutting.

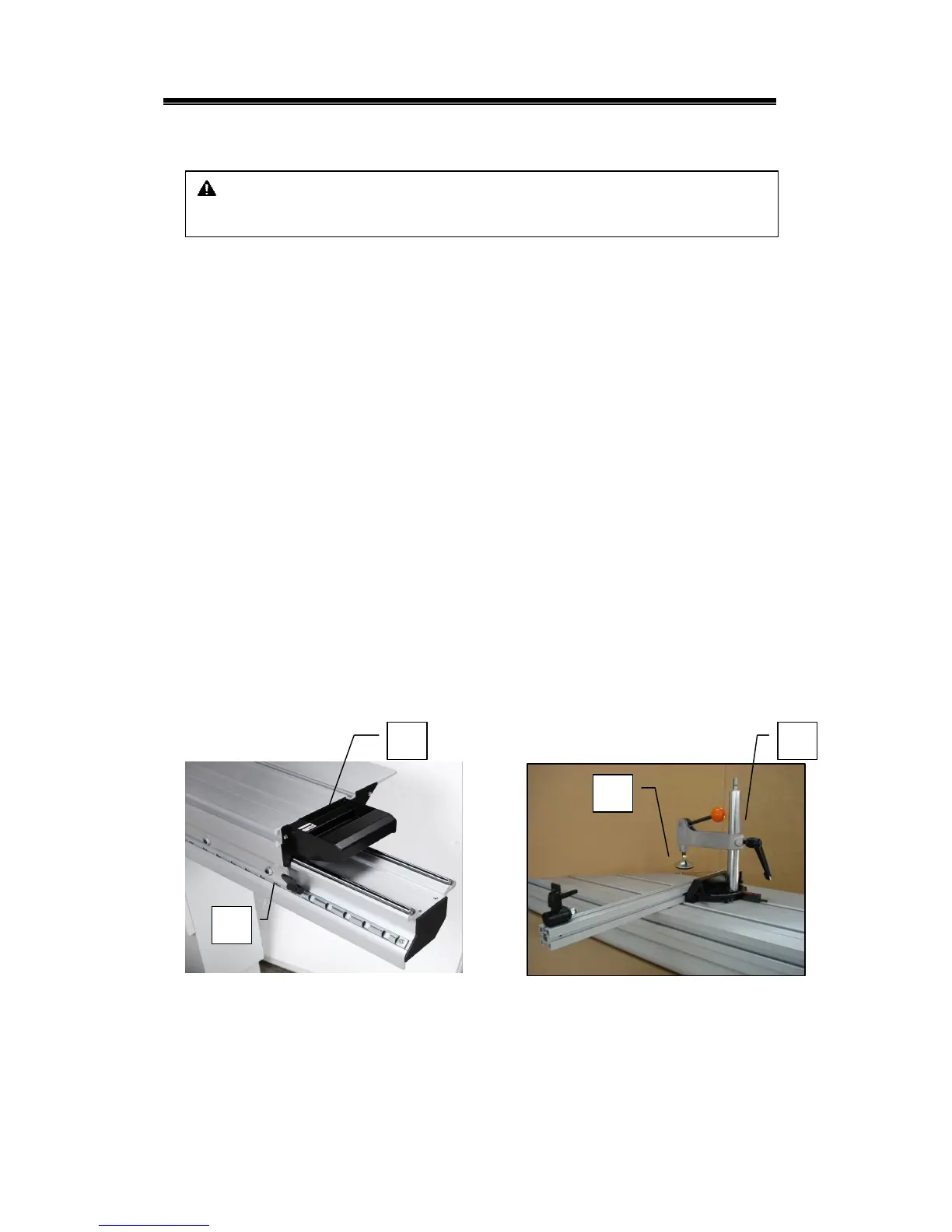

The sliding table is locked and unlocked by lever A (Fig. 4-6.1)

Lever up: sliding table unlocked

Lever down: sliding table locked

I.

USE OF SLIDING TABLE AND FRAME FOR LARGE PANELS

Longitudinal positioning of the frame

Lock/Unlock the sliding table by means of rod A for placing large work piece

1. Move the frame for your desired position with handle B (Fig. 4-6.1)

2. Lock knob A (Fig. 4-6.1) for fixing.

※ To remove the sliding table of the machine over the saw blade center, please

move the sliding table a little back for opening the second positioning design

II. USE OF THE HOLD DOWN

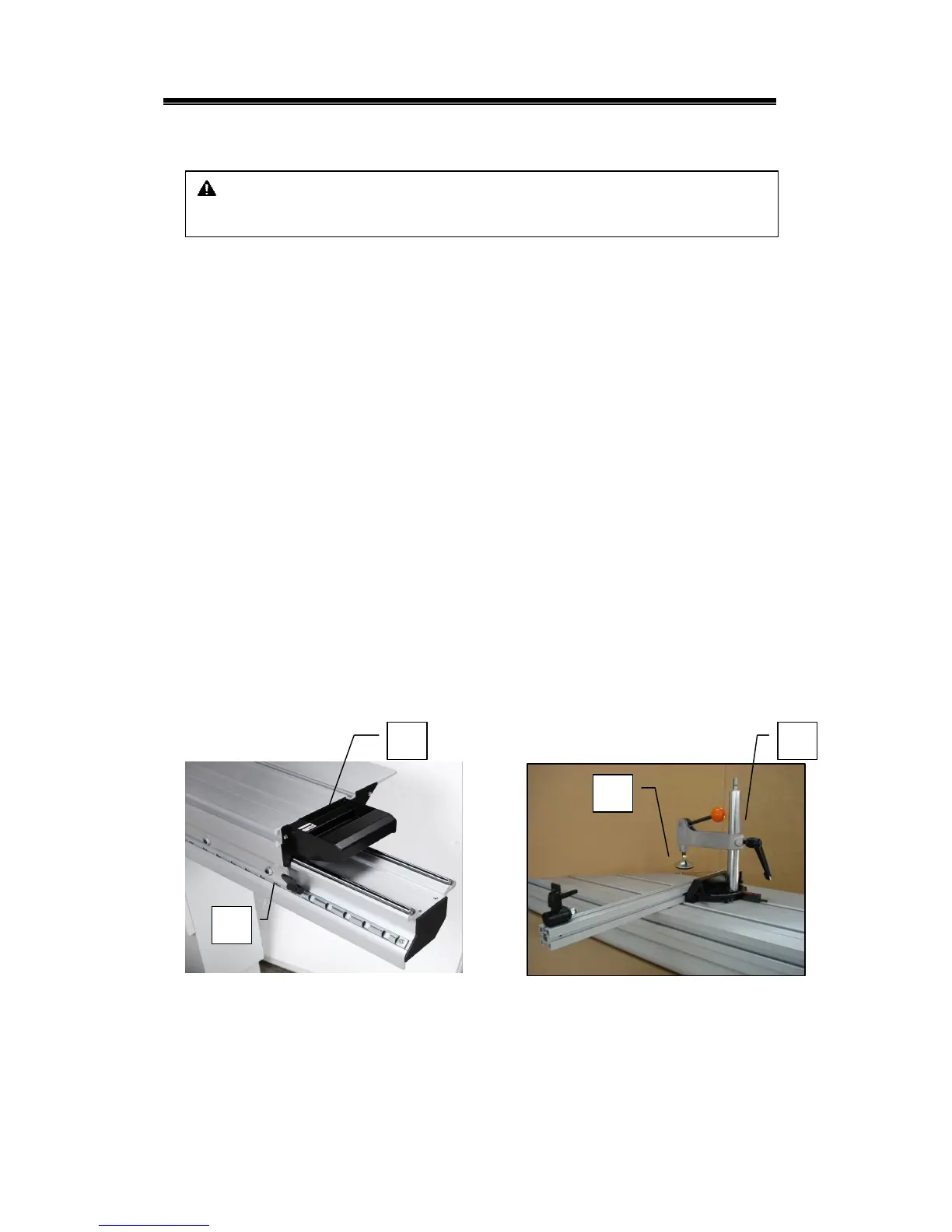

1. Loosen handle to adjust the foot height

※ To ensure a strong panel clamping, the foot shall be at a 2mm height from the

panel surface before lowering the lever.

2. By means of lever H(Fi

g. 4-6.2) lower foot F(Fig. 4-6.2) for clamping the work

piece

CAUTION:

Lock sliding table before placing heavy work piece for safe location.

Loading...

Loading...