124

9 Appendix

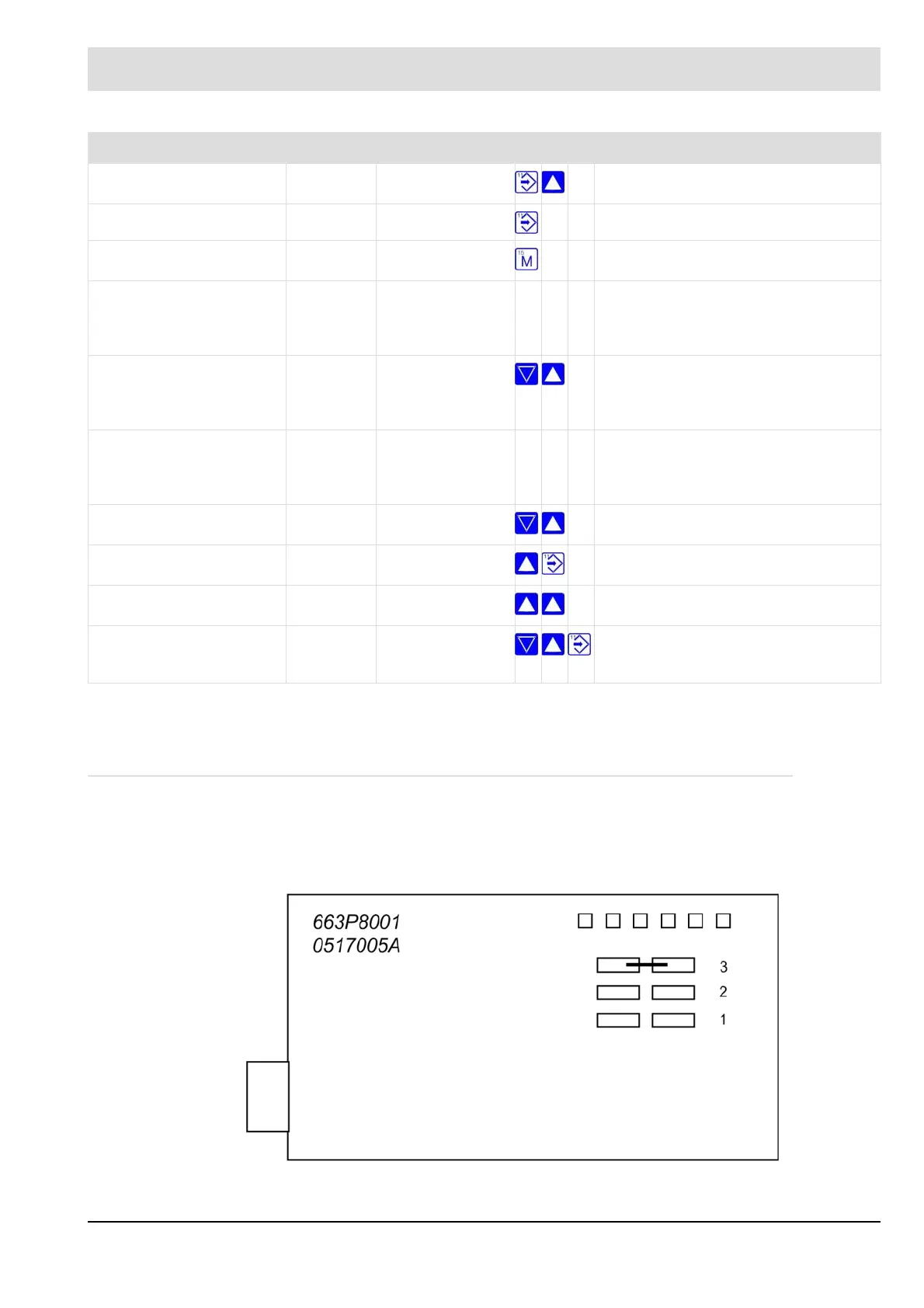

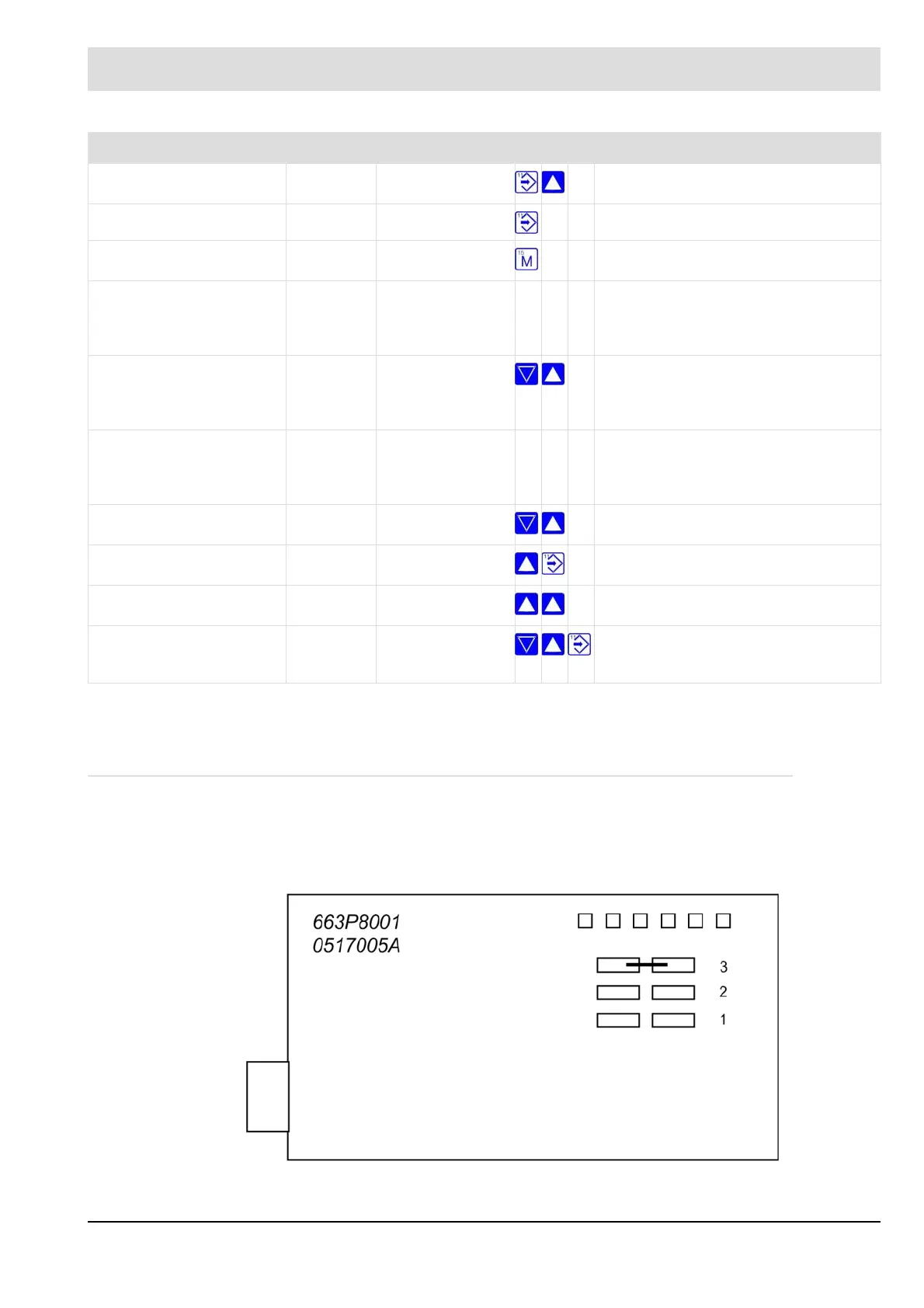

9.18 R. P. M. Sensor

9.18.1 Direct Connection to R. P. M. Sensor

(old version type 663P8001 until delivery date Sept. 03)

This option allows you to connect an inductive sensor of the company Turck as a speed feed-

back. On this configuration card 3 speed/ pulse ranges can be set at the factory.

The sensor is directly connected to terminal 42 and 43 (NAMUR interface)

Fig. 9-27 R.p.m. sensor 663P8001 up to September 2003

mode O

2

trim Status O

2

trim Mode O

2

trim,

press key 11 (Enter) to acknowledge

Calling up text messages Status O

2

trim press key 11 (Enter)

Display monitoring mode Automatic

Setting

hold and press 13

Change in mode T firing rate

value

Set base firing rate

or control mode

and set O

2

key 11 (Enter), Key 5

to finish: set the correction value to neutral

value and press key 4)

Adjusting correction value Firing rate

value

Set base firing rate

or control mode

and set O

2

O

2

trim

key 2 = Excess air

key 3 = Air deficiency

Change in mode T Setpoint

Set base firing rate

or control mode

and set O

2

Key 5

(to finish: set the setpoint back and press

key 4)

Changing O

2

setpoint value

Setpoint

T

O

2

trim

key 7 = more O

2

key 8 = less O

2

Calling up O

2

trim fault his-

tory

Status Automatic key 5 = browse fault history

key 11 = display description

Changing firing rate control-

ler setpoint

Firing rate

value

Control mode

Automatic

press keys 9 and 6 simultaneously,

when the display is blinking adjust the set-

point with keys 4 and 5, press key 11

(Enter) to store the setpoint

Action Display

Mode Buttons / Other

Loading...

Loading...