53

UserManualforELD2Servo

24VDC , and it is forbidden to connect these signal directly for the power of 24VDC , it will destroy the

hardware of servo driver.

6.2 Trial Run

After installation and connection is completed , check the following items before turning on the power:

Wiring?(especiallypowerinputandmotoroutput)

Shortorgrounded?

Looseconnection?

Unstablemounting?

Separationfromthemechanicalsystem?

6.2.1 Position Control

Notice:Youmustdoinspectionbeforepositioncontroltestrun.

Table7.4Par ameterSetupofPositionControl

No Parameter Name Input Value Unit

1 PA_001 control mode setup / 20 /

2 PA_312

Acceleration time setup

/

User-specified

millisecond

3 PA_313

Deceleration time setup

/

User-specified

millisecond

4 PA_314

Sigmoid acceleration/deceleration time setup

/

User-specified

millisecond

5 PA_005 Command pulse input select / 0 /

6 PA_007 Command pulse mode select / 0 /

7 PA_400 SI1 input selection Srv-on hex:0383 /

8 PA_518 Command pulse prohibit input invalidation / 1 /

SI1and SI2 function select:Pulse+Direction/Analog/GPIO

Pr4.00 Pr4.01

Direction 0 --

Pulse -- 0

Analog -- 0

GPIO1 Selectable --

GPIO2 -- Selectable

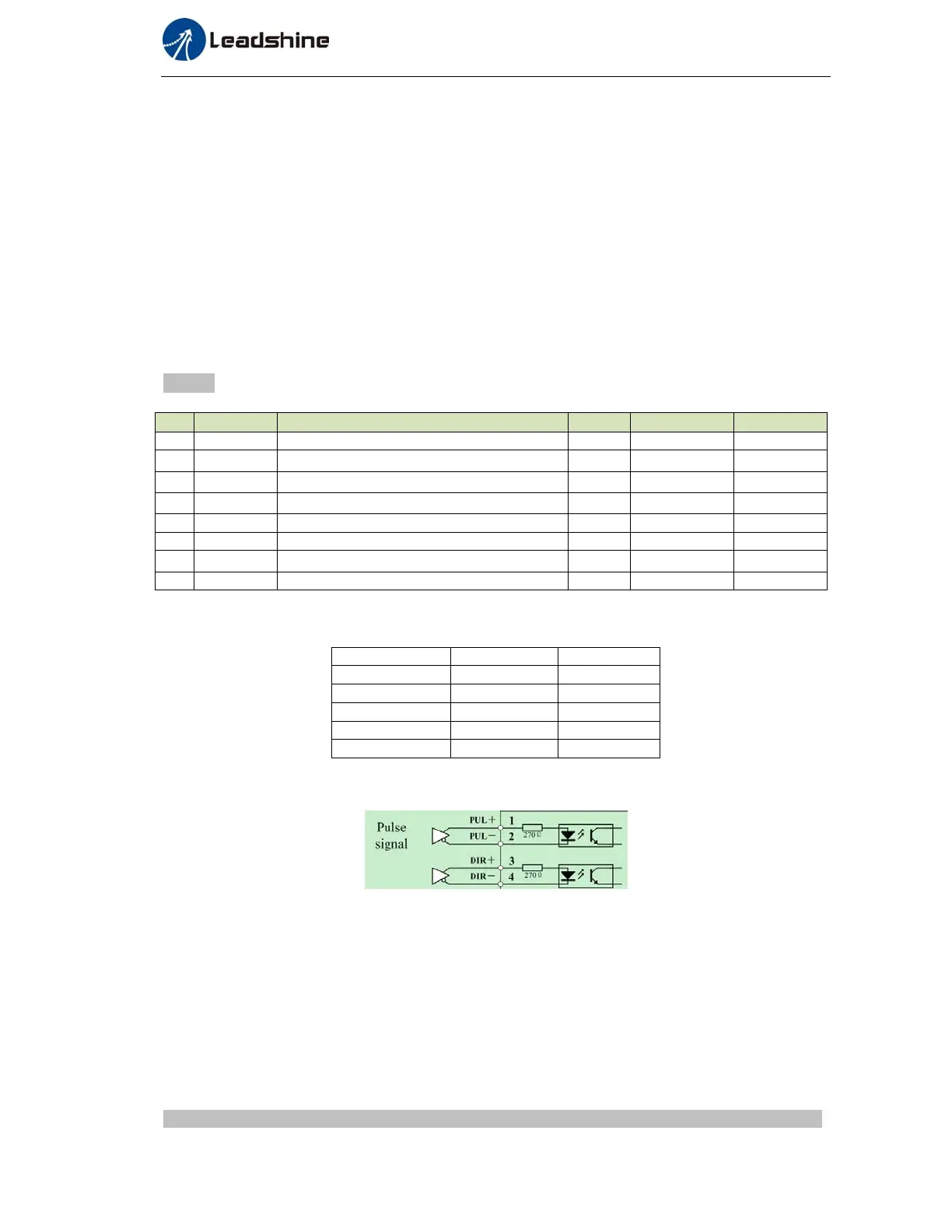

◆ Wiring Diagram

1). If the driver is enabled with internal signal, Pr403 should be set to 383, and connection of CN1 should

be set as following :

Figure7‐3ControlTerminalCN1SignalWiringinPositionControlModewithinternalservo‐onsignal

◆Operation Steps

1. Connect terminal CN1.

2. Enter the power (DC12V to 24V) to control signal (the COM + and COM-).

3. Enter the power to the driver.

4. Confirm the value of the parameters, and write to the EEPROM and turn off/on the power (of the driver)

5. Enter low-frequency pulse and direction signal to run the motor at low speed.

6.2.2 Velocity Control *

The default setting of ELD2 hardware can,t support velocity mode or Torque mode , pls contact

Loading...

Loading...