54

UserManualforELD2Servo

tech@leadshine.com for more details .

Notice:Youmustdoinspectionbeforevelocitycontroltestrun.

Table7.5ParameterSetupofVelocityControl

No Parameter Name input Setupvalue Unit

1 PA_001 Control mode setup / 21 /

2 PA_312 Acceleration time setup / User-specified millisecond

3 PA_313 Deceleration time setup / User-specified millisecond

4 PA_314

Sigmoid acceleration/deceleration time

setup

/

User-specified millisecond

5 PA_315 Zero speed clamping function select / 1 /

6

PA_300

Velocity setup internal and external

switching

/

User-specified /

7 PA_301 Speed Command direction selection / User-specified /

8 PA_302 Speed command input gain / User-specified Rpm/V

9 PA_303 Speed setting input reversal / User-specified /

10 PA_422 Analog input I(AI1) offset setup / User-specified 0.359mv

11 PA_423 Analog input I(AI1) filter / User-specified 0.01ms

12 PA_400 SI1 input selection Srv-on hex:0383 /

13 PA_401 SI2 input selection Analog hex:0001 /

14 PA_402 SI3 input selection IntSpd1 hex:0E00 /

15 PA_403 SI4 input selection IntSpd2 hex:0F00 /

16 PA_404 SI5 input selection IntSpd3 hex:1000 /

17 PA_405 SI6 input selection Vc-Sign hex:1200 /

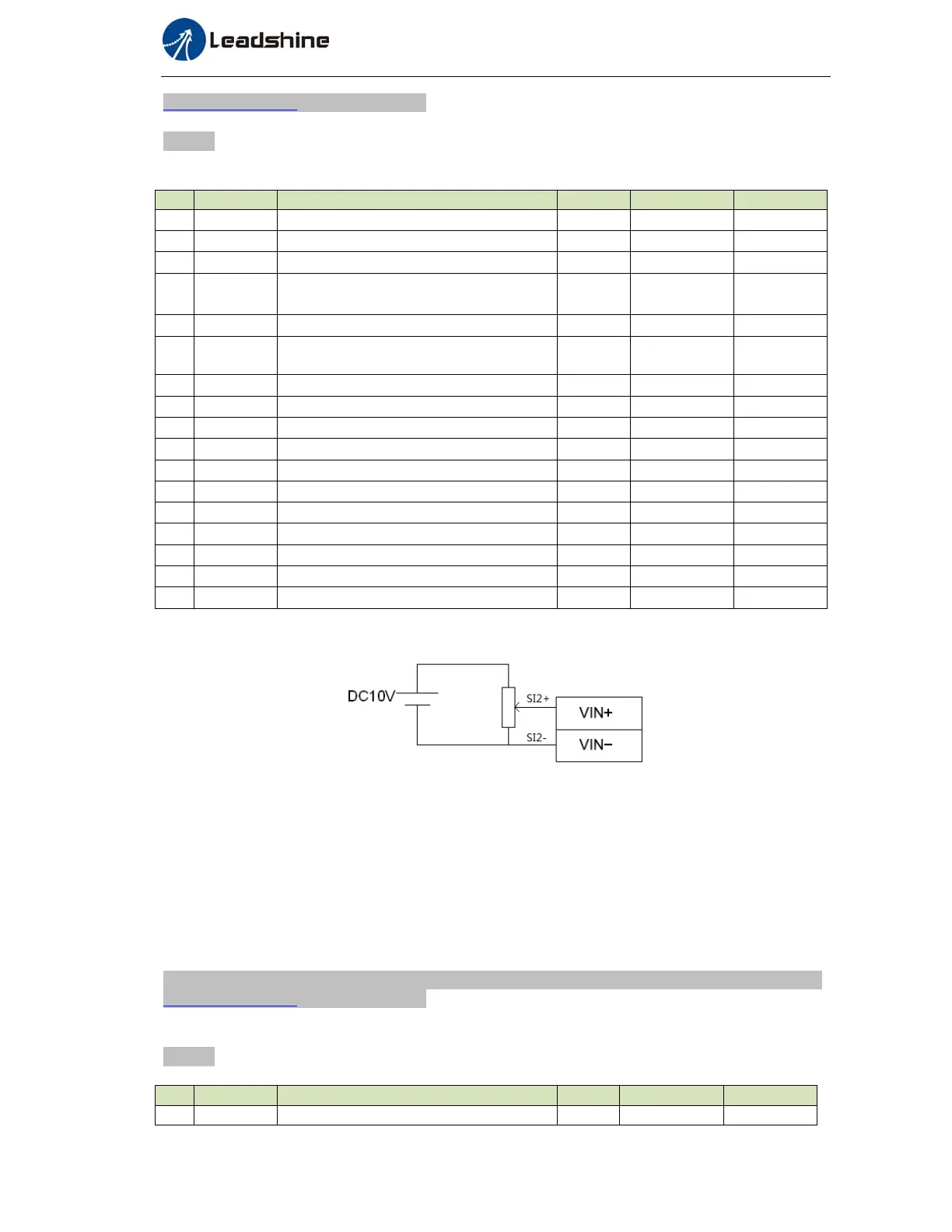

◆Wiring Diagram

◆Operation steps

1. connect terminal CN1.

2. Enter the power (DC12V to 24V) to control signal (the COM + and COM- ,while COM+ is for input

signal and COM- is for output signal).

3. Enter the power to the driver.

4. Confirm the value of the parameters, and write to the EEPROM and turn off/on the power (of the driver)

5. Apply DC voltage between velocity command input , VIN+ and VIN-, and gradually increase from 0V to

confirm the motor runs.

6.2.3 Torque Control *

The default setting of ELD2 hardware can,t support velocity mode or Torque mode , pls contact

tech@leadshine.com for more details .

Notice:Youmustdoinspectionbeforetorquecontroltestrun.

Table7.6ParameterSetupofTorqueControl

No Parameter

Name input Setupvalue Unit

1 PA_001 Control mode setup / 22 /

Loading...

Loading...