21

UserManualforELD2Servo

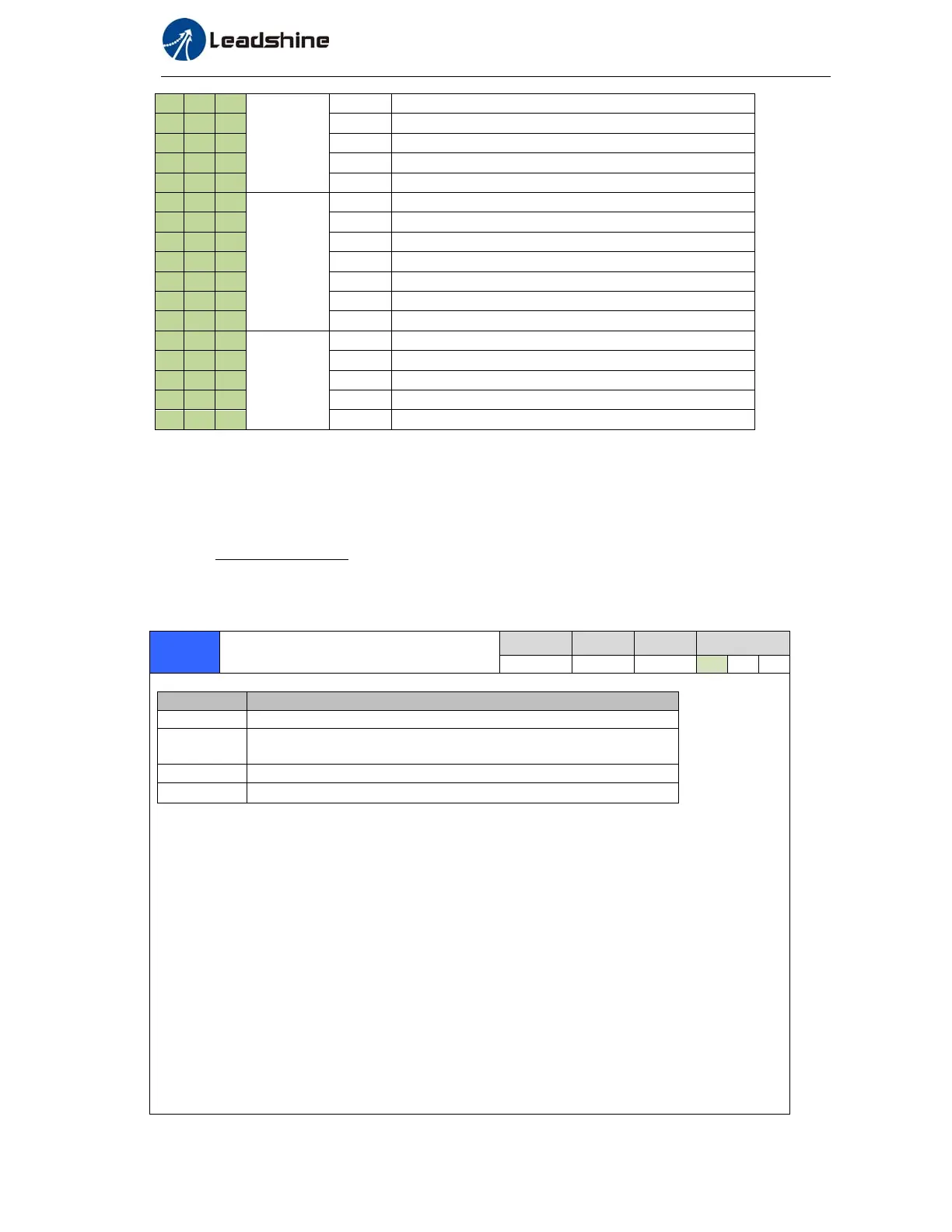

P S T

28 LED initial status

P S T

29 RS232 baud rate setup

P S T

30 RS485 baud rate setup

P S T

31 Axis address

P S T

35 Front panel lock setup

P S T

【Class6】

Special

Setup

03 JOG trial run command torque

P S T

04 JOG trial run command speed

P S T

08 Positive direction torque compensation value

P S T

09 Negative direction torque compensation value

P

20 distance of trial running

P

21 waiting time of trial running

P

22 cycling times of trial running

P S T

【Class7】

Factory

setting

00 Current loop gain

P S T

01 Current loop integral time

P S T

02-14 Setting of motor parameter

P S T

15 Motor model input

16 Encoder selection

4.2 Parameter Function

Here is the explanation of parameters, you can check them or modify the value using software Protuner or

the front panel of driver.

Contacttech@leadshine.comifyouneedmoretechnicalservice.

4.2.1

【

Class 0

】

Basic Setting

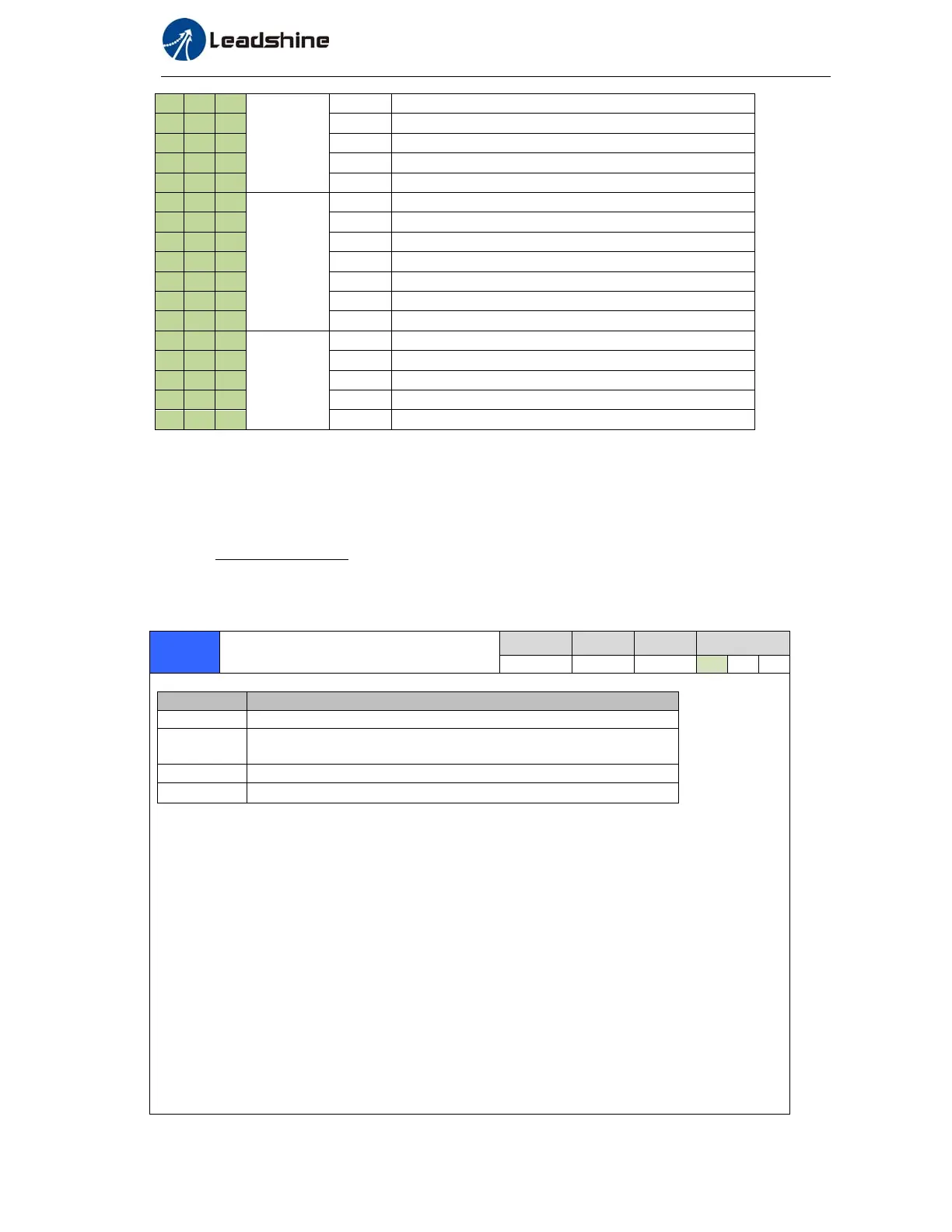

Pr0.00 Modelfollowingcontrol

Range unit default

Related

control mode

0 -32767 0.1Hz 0 P

Set up the bandwidth of MFC , it is similar to the response bandwidth

Setup value Meaning

0 Disable the function.

1

Enable the function , set the bandwidth automatically ,

recommended for most application .

2-10 Forbidden and reserved .

11-20000

Set the bandwidth manually , 1.1Hz – 2000Hz

MFC is used to enhance the performance of dynamic tracing for input command , make

positioning faster , cut down the tracking error , run more smooth and steady . It is very useful for

multi-axis synchronous movement and interpolation, the performance will be better.

The main way to use this function :

a. Choose the right control mode : Pr001 = 0

b. Set up the inertia of ratio : Pr004

c. Set up the rigidity : Pr003

d. Set up the Pr000 :

1) If no multi-axis synchronous movement , set Pr000 as 1 or more than 10 ;

2) If multi-axis synchronous movement needed , set Pr000 as the same for all the axes .

3) If Pr000 is more than 10 , start with 100 , or 150 , 200 , 250 , …. .

Caution:

1. Set up the right control mode , the right inertia of ratio and rigidity firstly .

2. Don’t change the value of Pr000 when the motor is running , otherwise vibration occurs

3. Set up a small value from the beginning if using it in manual mode , smaller value means

running more smooth and steady , while bigger one means faster positioning

Loading...

Loading...