Rectifying faults

132

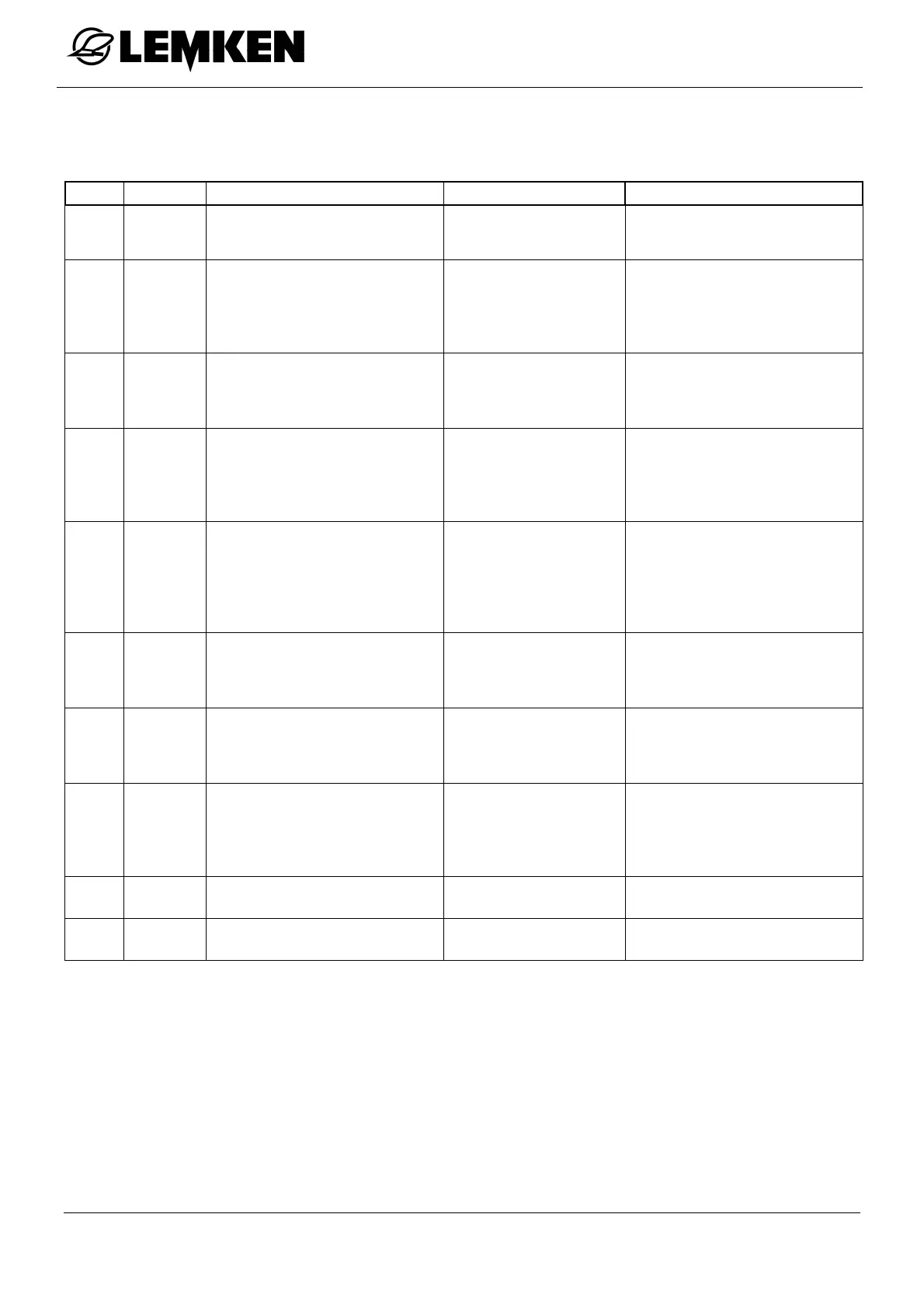

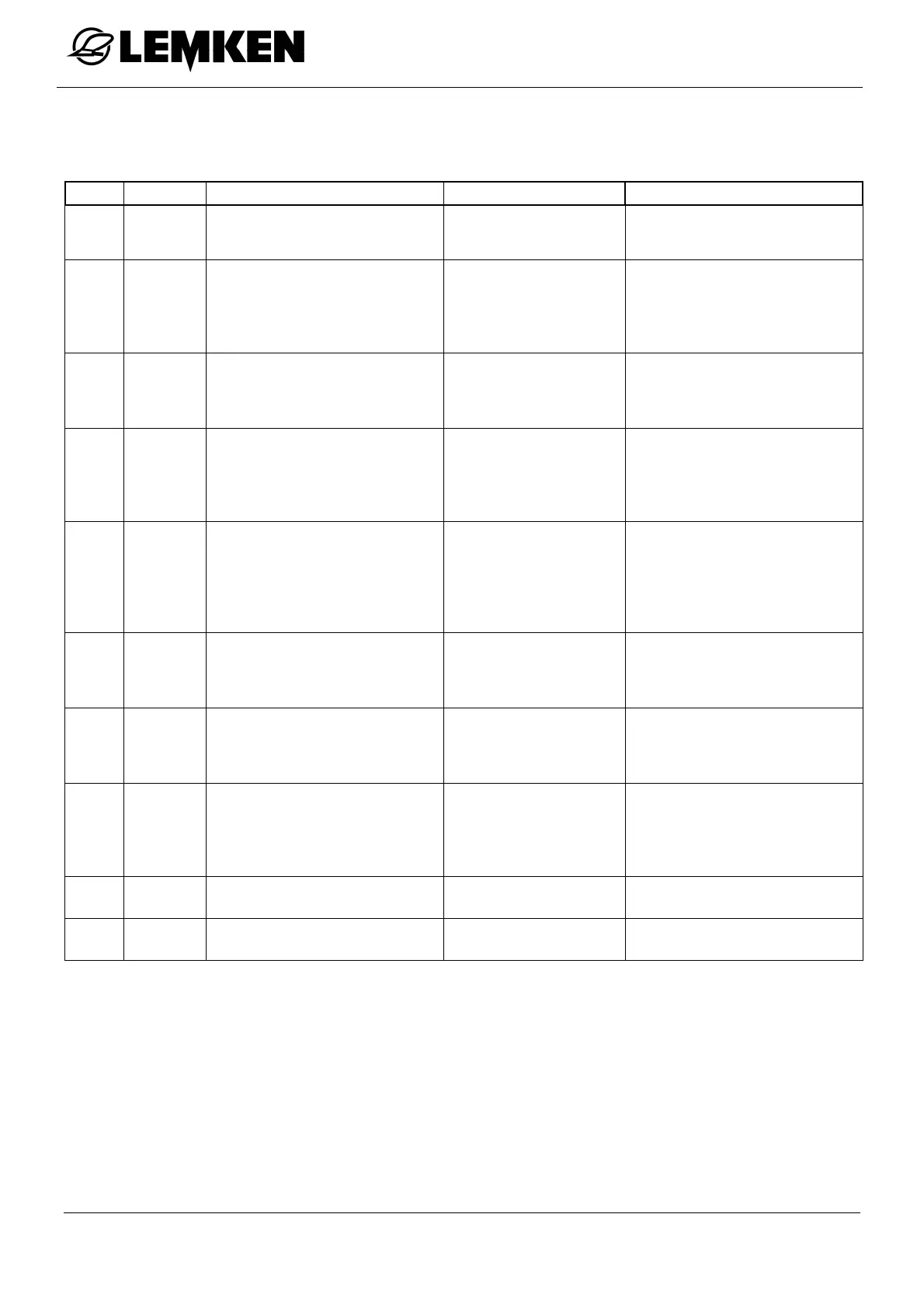

14.2 A - Warning/fault/note

These differ depending on the device version.

Code Group Description Possible cause Corrective measure

A01 Warning

Different indication of the length

section width relative to the

working width

Incorrect entry Correct entry

A02 Fault

Deviation between the target

value and actual value applica-

tion quantity l/ha with closing

rotary control valve

Rotary control valve

does not move

Speed too low

Control valve visual inspec-

tion

Increase speed

Observe control thresholds

A03 Fault

Both sensors of the pendulum

lock are switched

Fault in the cable

Fault in the sensor

Wrong circuit dis-

tance of the sensors

Cabling visual inspection

Sensors visual inspection

Check sensor circuit distance

A04

Informa-

tion

Maximum filling quantity reached

Overfilling

Incorrect entry

for electric filling level

display, possible in-

correct sensor value

Correct entry

A05

Informa-

tion

Minimum filling quantity reached

Remaining quantity

reached

Incorrect entry

for electric filling level

display, possible in-

correct sensor value

Top up

Correct entry

Check sensor

A06

Informa-

tion

Maximum spraying pressure set

reached

Incorrect entry

Possible erroneous

sensor

Fault during spraying

Correct entry

Reduce spraying pressure

A07

Informa-

tion

Minimum spraying pressure set

reached

Incorrect entry

Possible erroneous

sensor

Fault during spraying

Correct entry

Increase sprayer pressure

A08 Fault

Deviation between the target

value and actual value applica-

tion quantity l/ha with opening

rotary control valve

Rotary control valve

does not move

Speed too high

Control valve visual inspec-

tion

Reduce speed

Observe control thresholds

A09 Fault

Pressure sensor signal errone-

ous

Fault in the cable

Fault in the sensor

Check cabling

Check sensor

A10 Fault

Filling level sensor signal erro-

neous

Fault in the cable

Fault in the sensor

Check cabling

Check sensor

Loading...

Loading...