5 Maintenance

Engine

Cleaning with compressed air

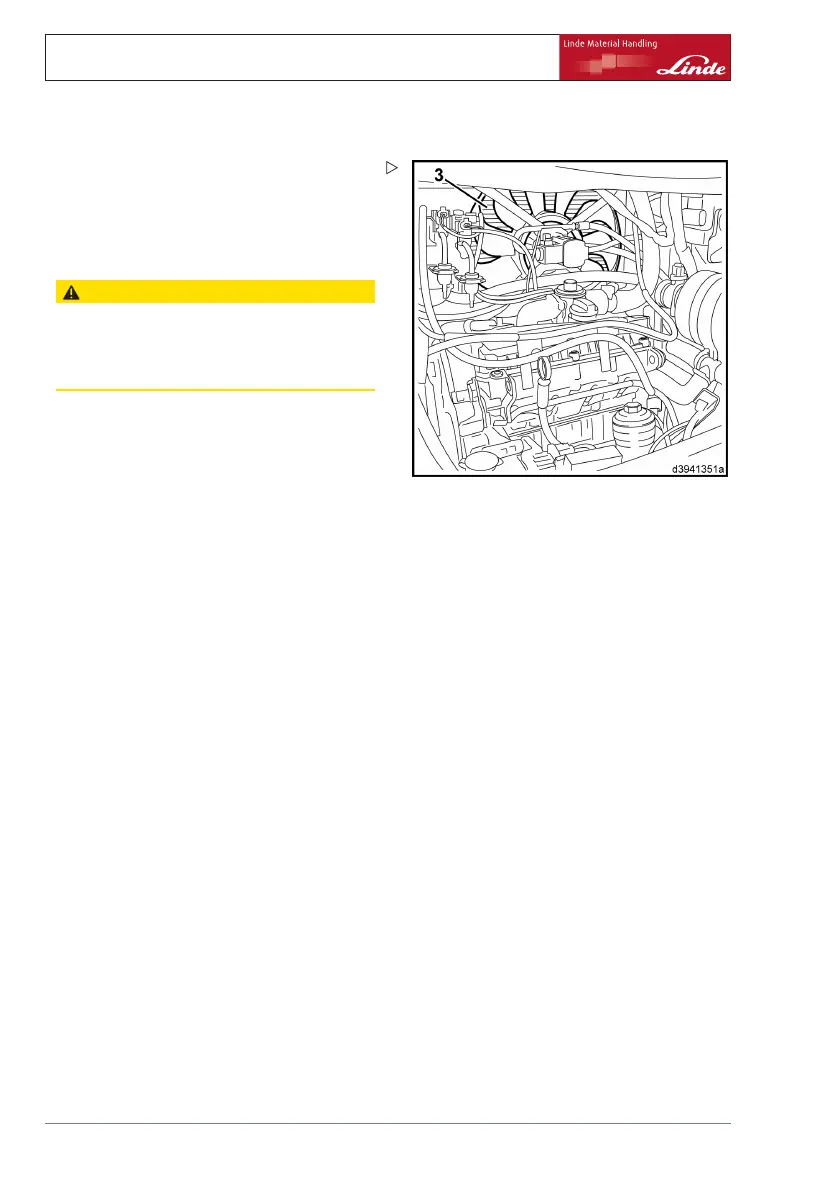

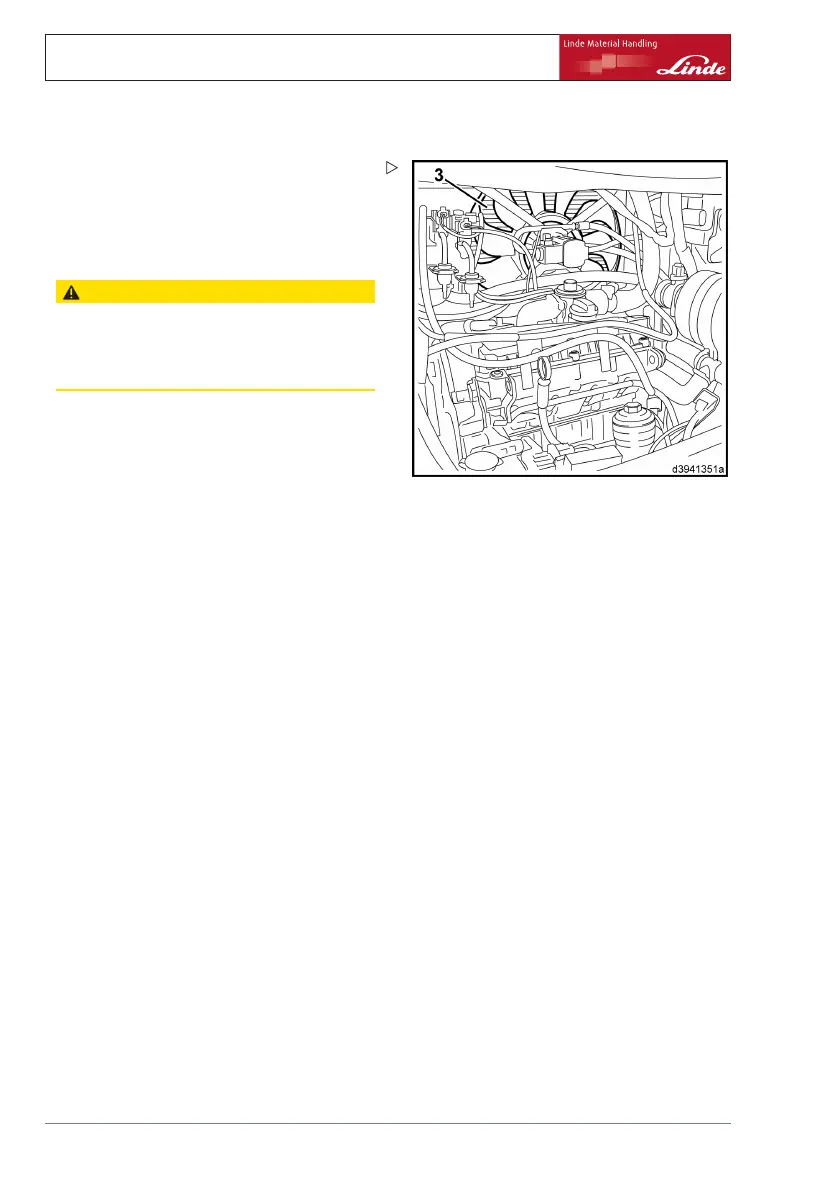

¾ Blow out the cooler (3) from the engine side

using compressed air.

¾ Rinse out the released dirt usi

ng a water jet.

Cleaning with cleaner solv

ent

CAUTION

Humidity must not penetrate the three-phase

alternator.

Therefore, protect it from direct contact with the

water jet.

¾ Spray the cooler (3) with a conventional

cleaner solvent and leave it to work for

approx 10 minutes.

¾ Spray the cooler from the engine side with a

direct jet of water until it is clean.

¾ Warm up the engine.

This evaporates the water residue to prevent

the formation of rust.

¾ Check the connection screw joints, cooling

hoses and the pipes on the water cooler and

hydraulic cooler for leaks.

¾ Replace porous hoses. Re-tighten hose

clips if necessary.

¾ Refit the cover sheet (1).

Checking the condition and secure

positioning of the engine support and

engine mounting

The elastic bearings used for the engine

suspension are subjected to high loads.

Their service life is limited by the operating

conditions.

134 Operating Instructions – 394 807 10 01 EN – 07/2011

Loading...

Loading...