Maintenance 5

Load lift system

Clean sideshift (special equipment)

and grease, check fastening

ENVIRONMENT NOTE

Observe information about working materials.

NOTE

The sideshift should be greased whenever

the truck is washed. Use lubricating grease

complying with the recommendations for

working materials.

¾ Clean sideshift with steam jet.

¾ Check hydraulic lines

for scuffing and

replace if necessary.

¾ Check hydraulic connections and fastening

elements for secure positioning and wear

and tighten/replace if necessary.

¾ Check cylinders for leaks.

¾ Check piston rods fo

r damage.

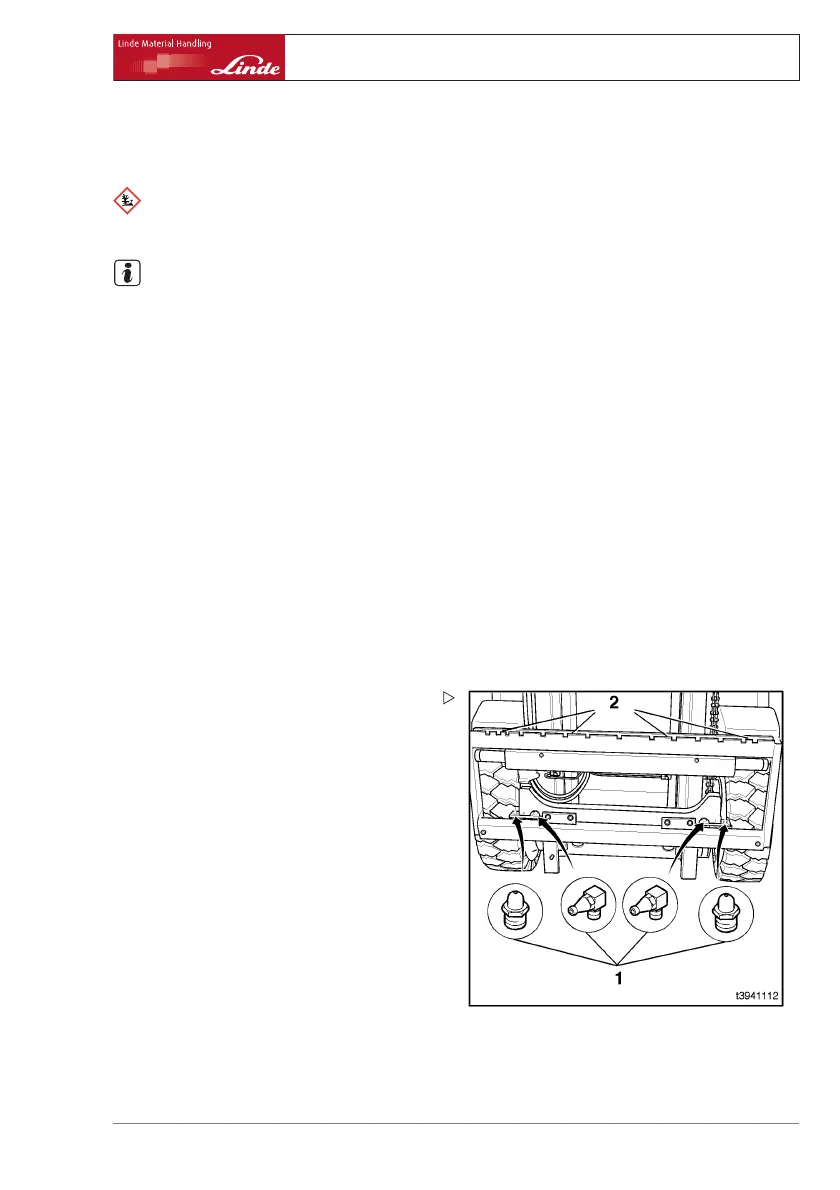

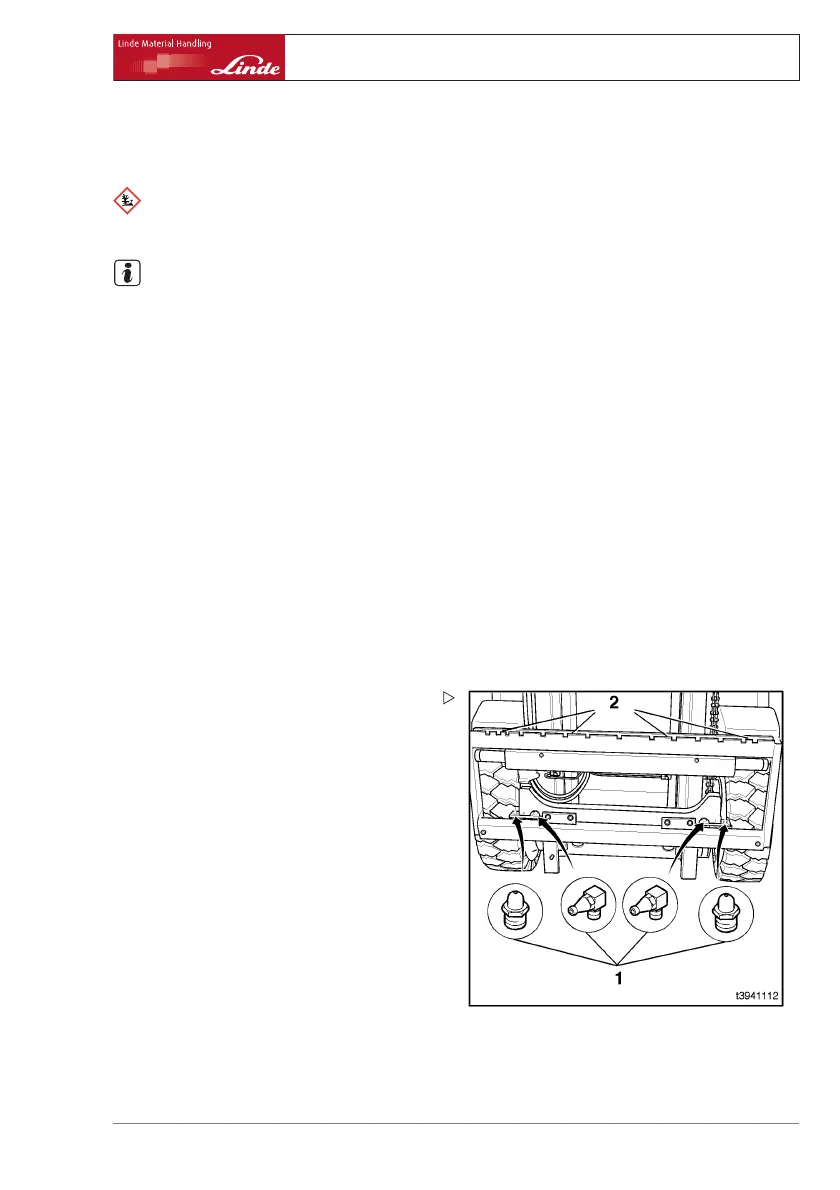

¾ Adjust the fork arms so that the 4 lubricating

nipples (1) are accessible.

¾ Let down sideshift until fork arms touch the

ground.

¾ Apply lubricating

grease to lubricating

nipples (1) of supp

ort rollers on fork carriage

until grease esca

pes at the side.

¾ Apply lubricating grease to lubricating

nipples (2) of wear strips on fork carriage

at top until grease escapes at the side.

Operating Instructions – 394 807 10 01 EN – 07/2011 189

Loading...

Loading...