1) After the machine is powered on, inspect whether instrument indications are normal;

2) In case of any failure, first inspect whether the sensors are damaged or not; in case

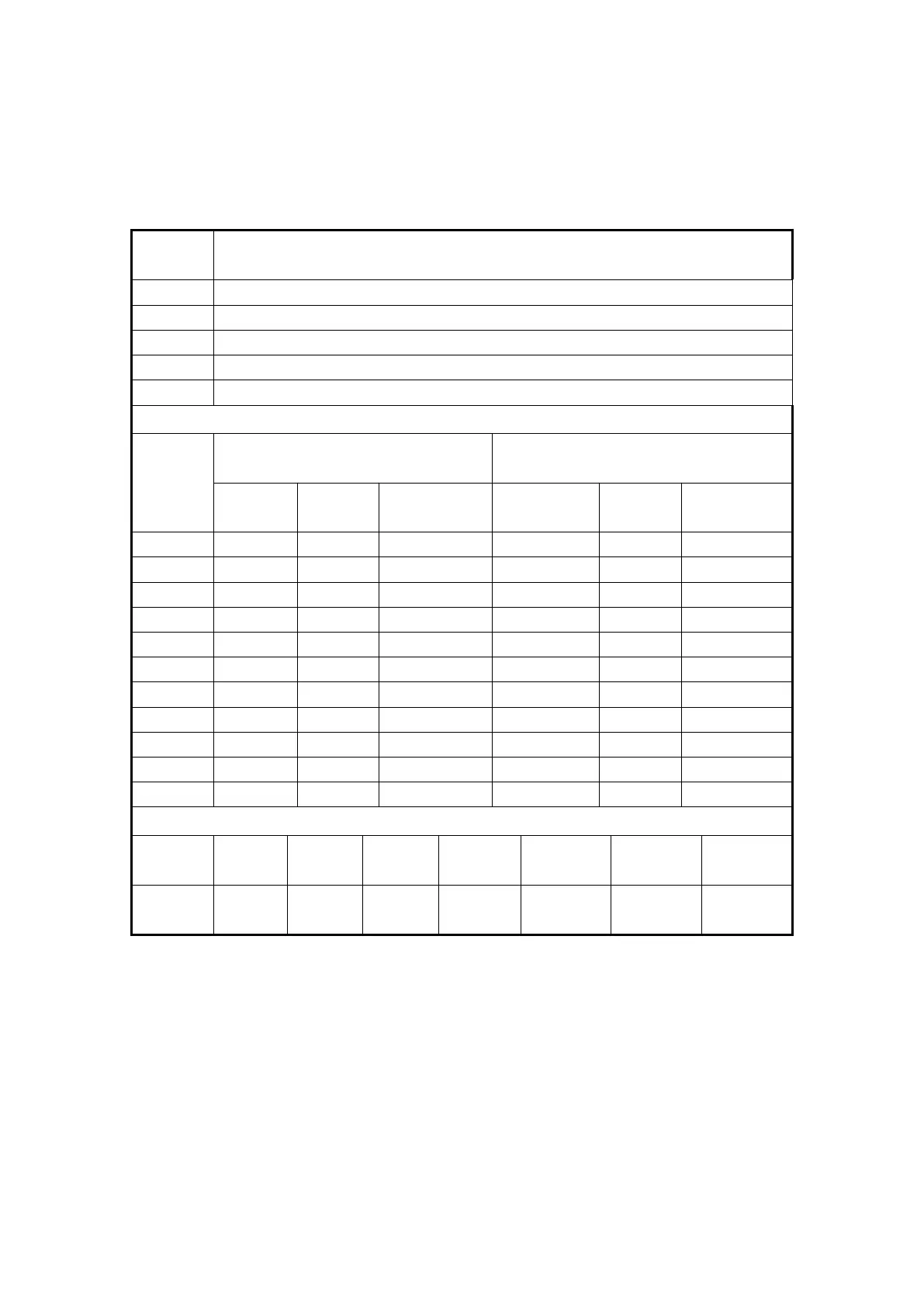

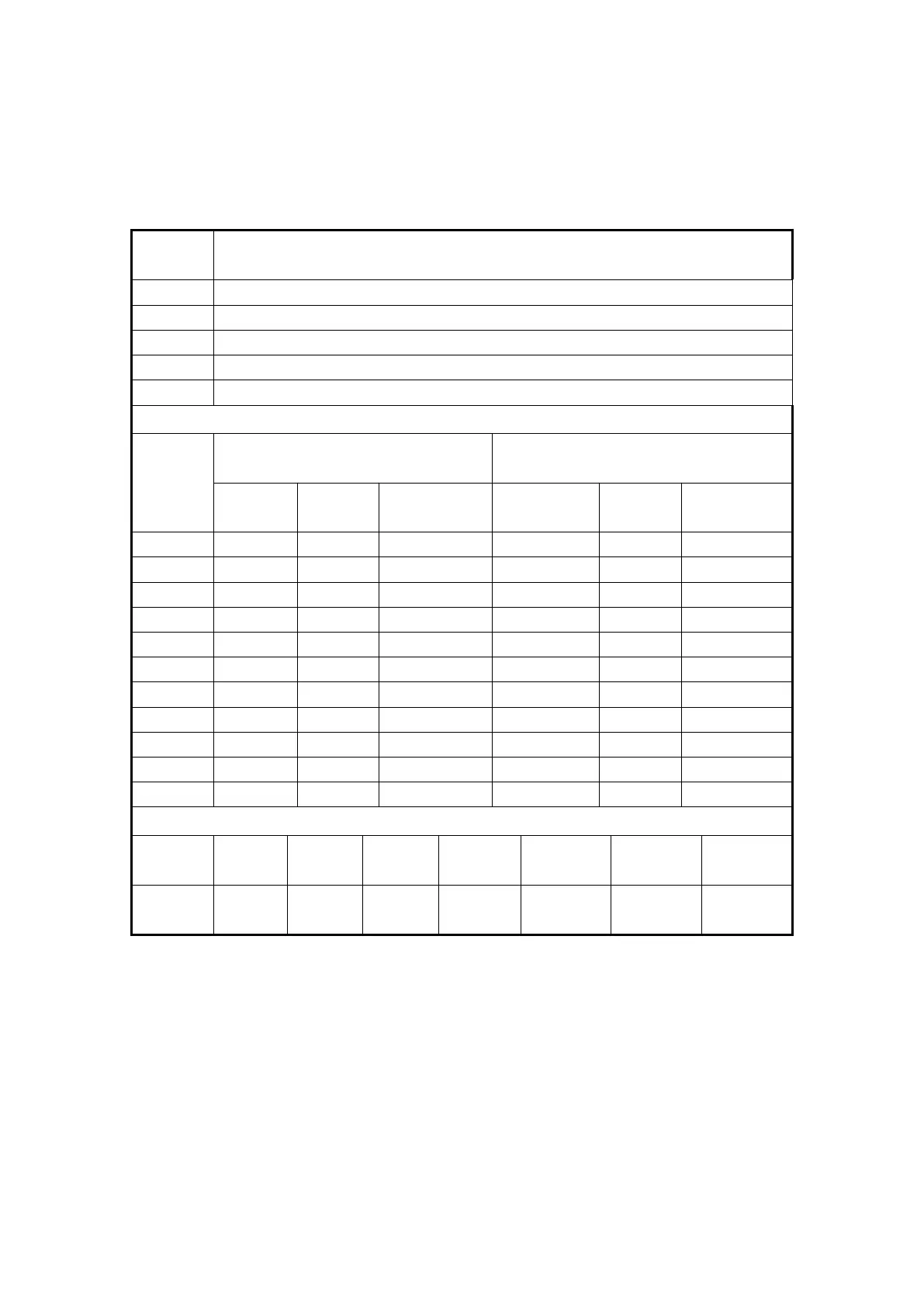

of no damage, inspect the corresponding temperatures in the following table to confirm

whether the resistances meet the requirements in the table below.

3) If the sensor is fault-free, then inspect the cable from each sensor to the front of the

instrument, to inspect whether

it

is normal without damage or not.

4) If there is no damage, then loose, short circuit and, connect a small resistor in series,

then the indicator will display the max. value, the indicating hand does not point to a

mark, if

it

cannot normally indicate, and then replace the meter.

5.9.3

5.9.3

5.9.3

5.9.3 SOLDERING

SOLDERING

SOLDERING

SOLDERING

Comparison of the temperature sensor parameters

Pressure sensor parameters comparison

1.0MPa hydraulic and pneumatic

sensors

2.5MPa air pressure sensor

General Parameters of Fuel Sensor

Loading...

Loading...