Do not bend or hammer high-pressure pipeline,

do not install abnormal bending or damaged pipe

or tube on the machine. Repair loose or

damaged fuel and lubricant pipeline and pipe or

tube installed in hydraulic system.

Leakage may cause fire. For repair or

replacement, please contact the designated

dealer of LONKING Holdings Limited.

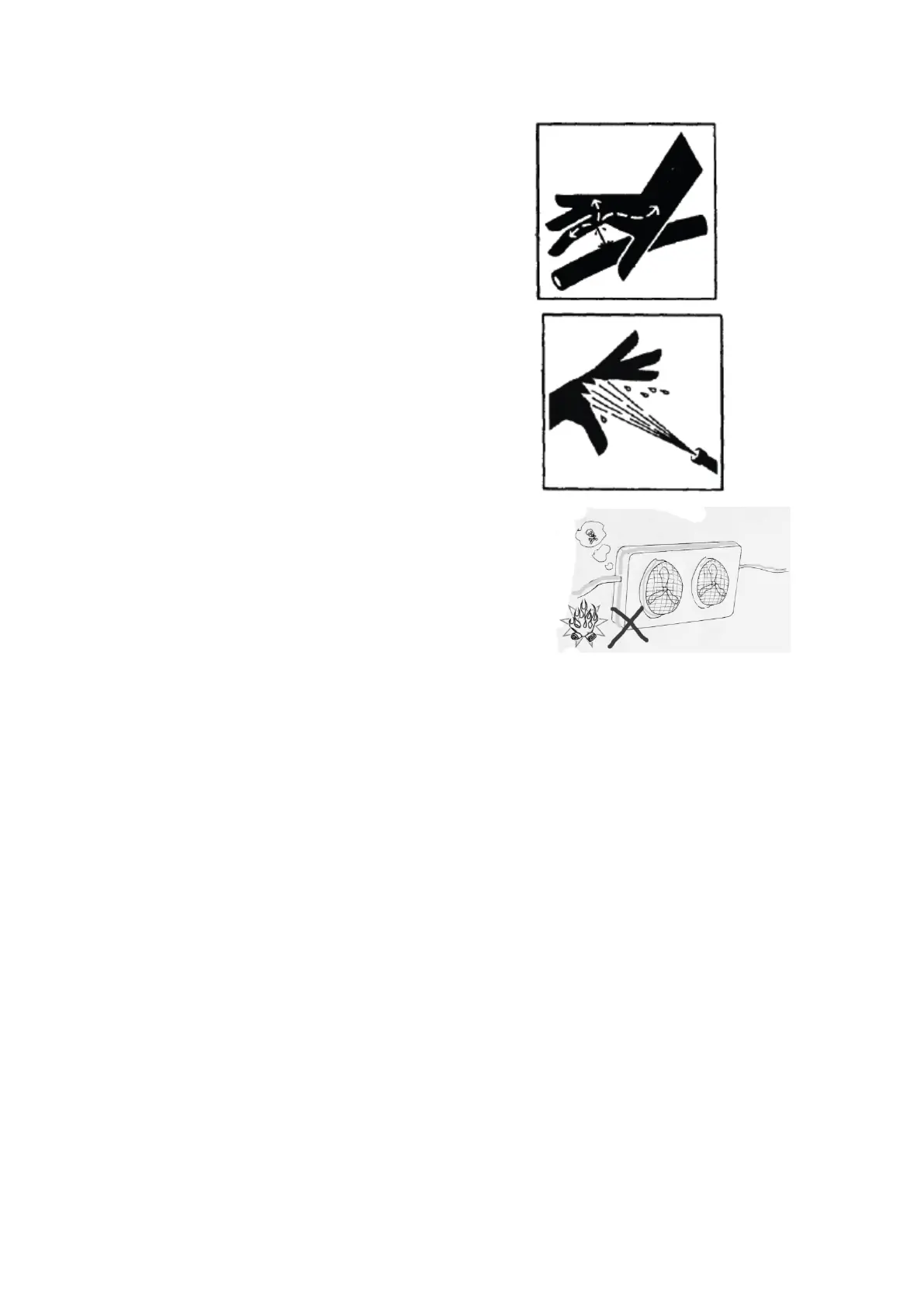

Please carefully check all pipelines, hard pipes

and flexible pipes, tighten all joints according to

specified tightening torque. Do not check the

leakage with bare hands, but check them with

board or cardboard.

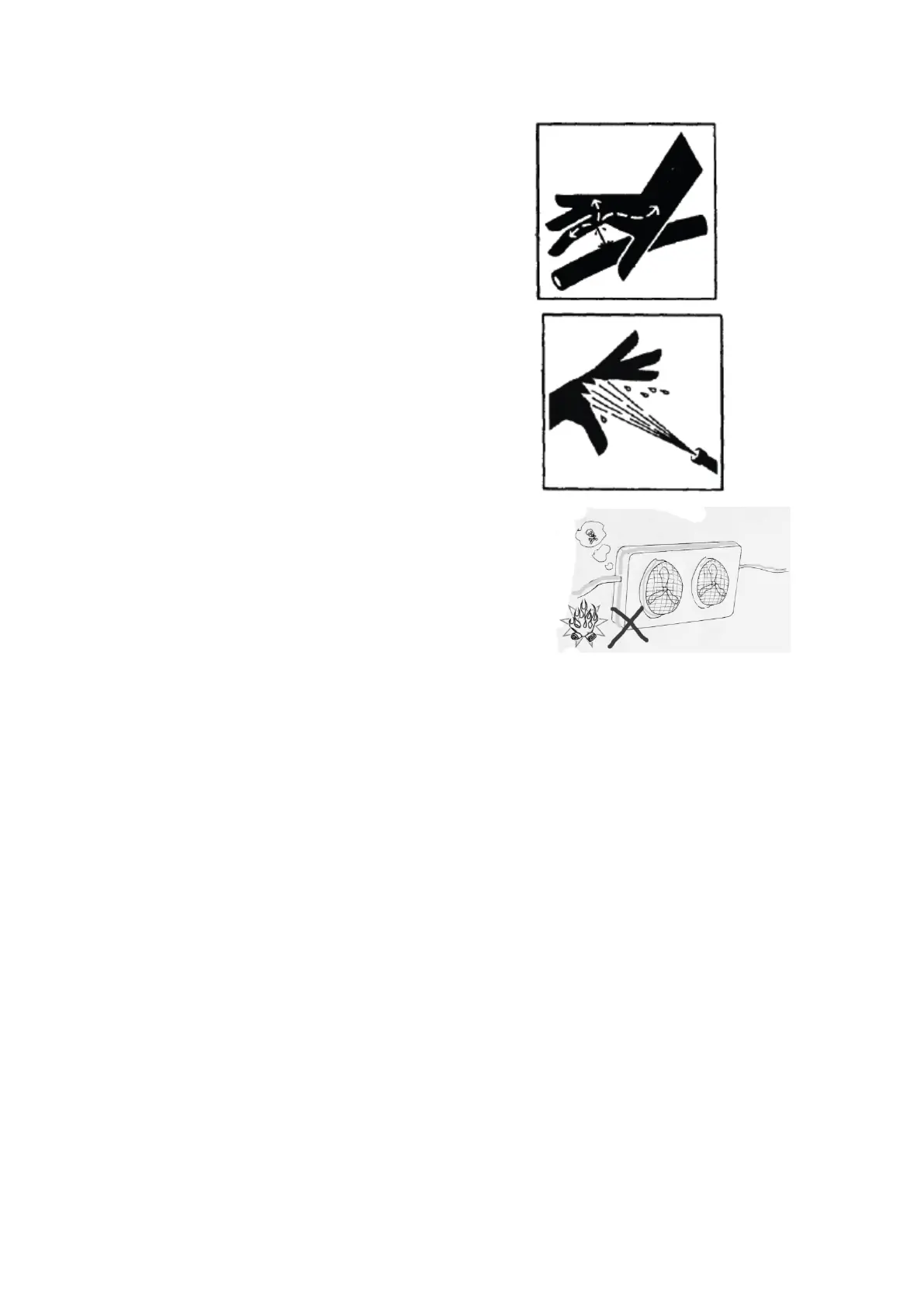

Even a pinhole size pressure liquid leakage may

penetrate muscle and cause death. If the solution

sprays out to the skin, please contact with

surgeons who is familiar with this injury for cure

within a few hours. If the following faults

happened, the part s should be replaced:

1) connector damaged or leaked; 2) outer layer

of the tube worn or cut and strengthening steel

wire bare; 3) local uplift of the tube; 4) the tube

has obvious torsion or deflection; 5)

strengthening steel wire of the tube embedded in

outer layer; 6) end c onnector dislocation.

Loading...

Loading...