Grove Published 11-22-2016, Control # 345-12 4-7

RT9130E-2 SERVICE MANUAL BOOM

extension of the sections, an indictor light on the console

remains illuminated as long as the unsynchronized condition

persists, and the inner mid or center mid section telescope

cylinder selection is indicated by respective lights on the

control panel, thereby allowing the operator to telescope the

section[s] appropriately). As long as the system continues to

detect the unsynchronized condition, and/or the manual

mode is selected, the rated capacity limiter/lockout system

also limits the allowable load moment to 22,046 lb (10,000

kg) or 50% of the rated capacity at the particular prevailing

boom length, the intent being that, while the sections are

unsynchronized, any hook load will be deposited, only the

hookblock remaining suspended while the necessary

adjustment of the boom sections occurs: only when

synchronization has been achieved will the system reset and

normalize the load monitoring system when switched back to

Automatic mode.

The standard used by the system to define an

unsynchronized condition is an error or +/-3% of the full

extension value of one section. Since the inner mid, center

mid, and the outer mid/fly combination all extend individually,

compliance with the criterion can only be assessed at

section extensions corresponding to the points of

changeover of movement from section to section. Therefore,

the system reviews the extension of each section prior to

permitting the changeover, and unless all section extension

values are within 3% of their programmed changeover

length, the system defaults to the out-of-synchronization

condition described above. The same default occurs if, in the

course of operation, any boom section moves out of

synchronization to a length corresponding to one of its own

changeover lengths (since it then invokes the +/-3% criterion

against the other sections), or moves away from such a

changeover length by more than the 3% margin.

BOOM MAINTENANCE

Removal

NOTE: The boom weighs approximately 36,610 lb (16,606

kg). Removal of the swingaway boom extension

will simplify boom removal, therefore, the above

weight is for the boom without the swingaway

boom extension attached.

1. Extend and set the outriggers to level the crane and

ensure the boom is fully retracted and in a horizontal

position over the front of the crane.

2. If equipped, remove the swingaway boom extension and

aux nose according to the removal procedures in this

section.

3. Remove the hookblock or headache ball and wind all the

wire rope onto the hoist drum.

4. Position the boom to make sure that the lift cylinder is

resting securely in the lift cylinder support.

5. Attach a lifting device to the boom to provide for equal

weight distribution.

6. Tag and disconnect any electrical wiring from the boom.

7. Tag and disconnect the hydraulic lines to the lower

telescope cylinder and plug.

8. Remove the capscrews, washers and nut fasteners

securing the base cover to the top of the boom base

section near the pivot shaft. Remove the cover.

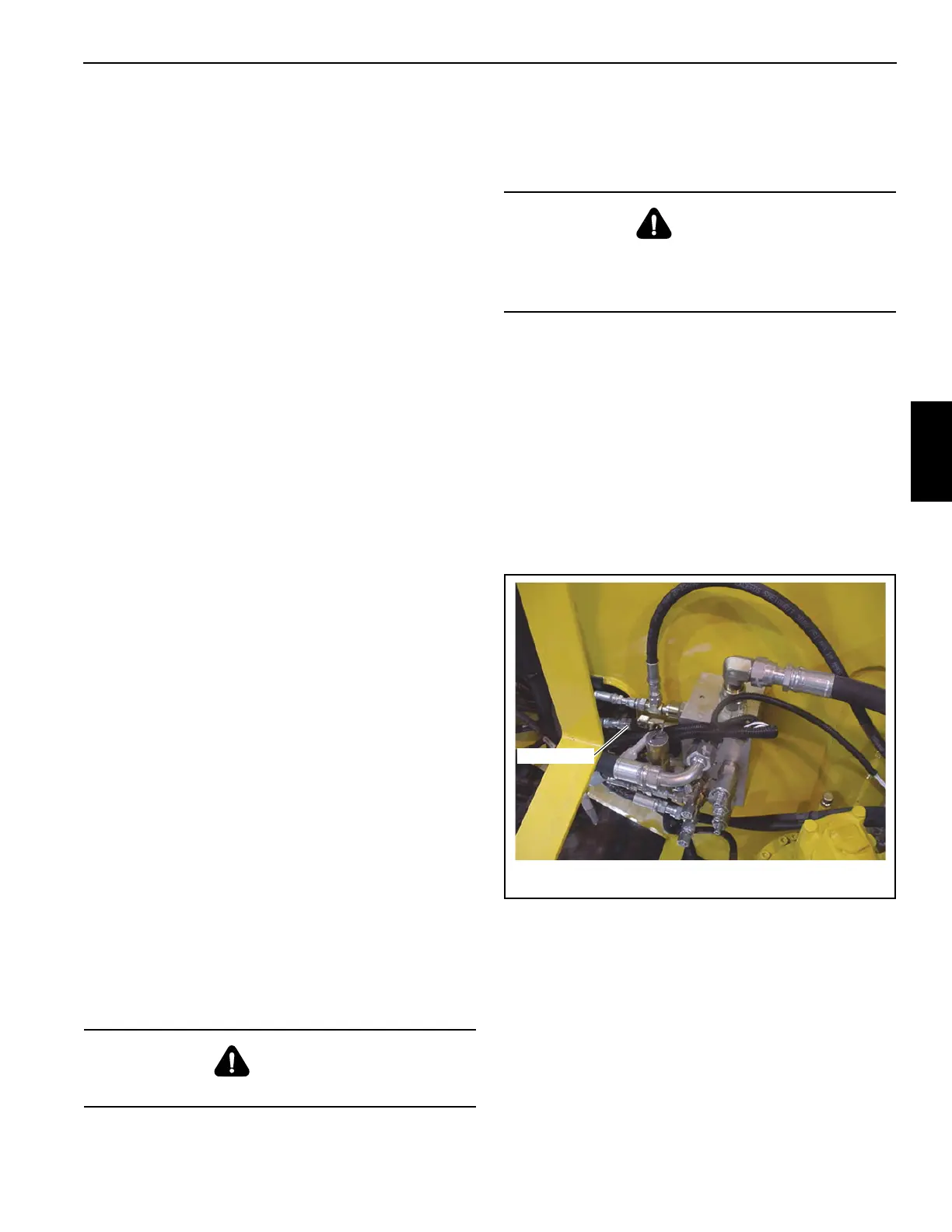

9. With the engine off, disconnect the hose reel supply line

from the side of the valve bank (Figure 4-3). Plug or cap

all openings.

10. Using the S-hook, secure the spring loaded side of the

hose reel in the turntable to prevent the reel from rotating

before proceeding to the next step (Figure 4-4). Reach

through the hole in the top of the base section and tag

and disconnect the hose reel lines from the hydraulic

manifold that is mounted on the rear of the center mid.

Cap all lines and openings. Feed the hoses through the

rollers at the rear of the base. If crane is being readied

for transport, secure the hoses to the hoist.

CAUTION

Wear gloves when handling wire rope.

DANGER

Crushing Hazard!

Ensure blocking and lifting devices are capable of

supporting the boom assembly.

Supply Hose

FIGURE 4-3

7700-2

Loading...

Loading...