6-18 Published 11-22-2016, Control # 345-12

SWING SYSTEM RT9130E-2 SERVICE MANUAL

Hydraulic Swivel

Description

Each of the ports on the spool and case of the swivel is

stamped with the port number. The function of each port is

described below.

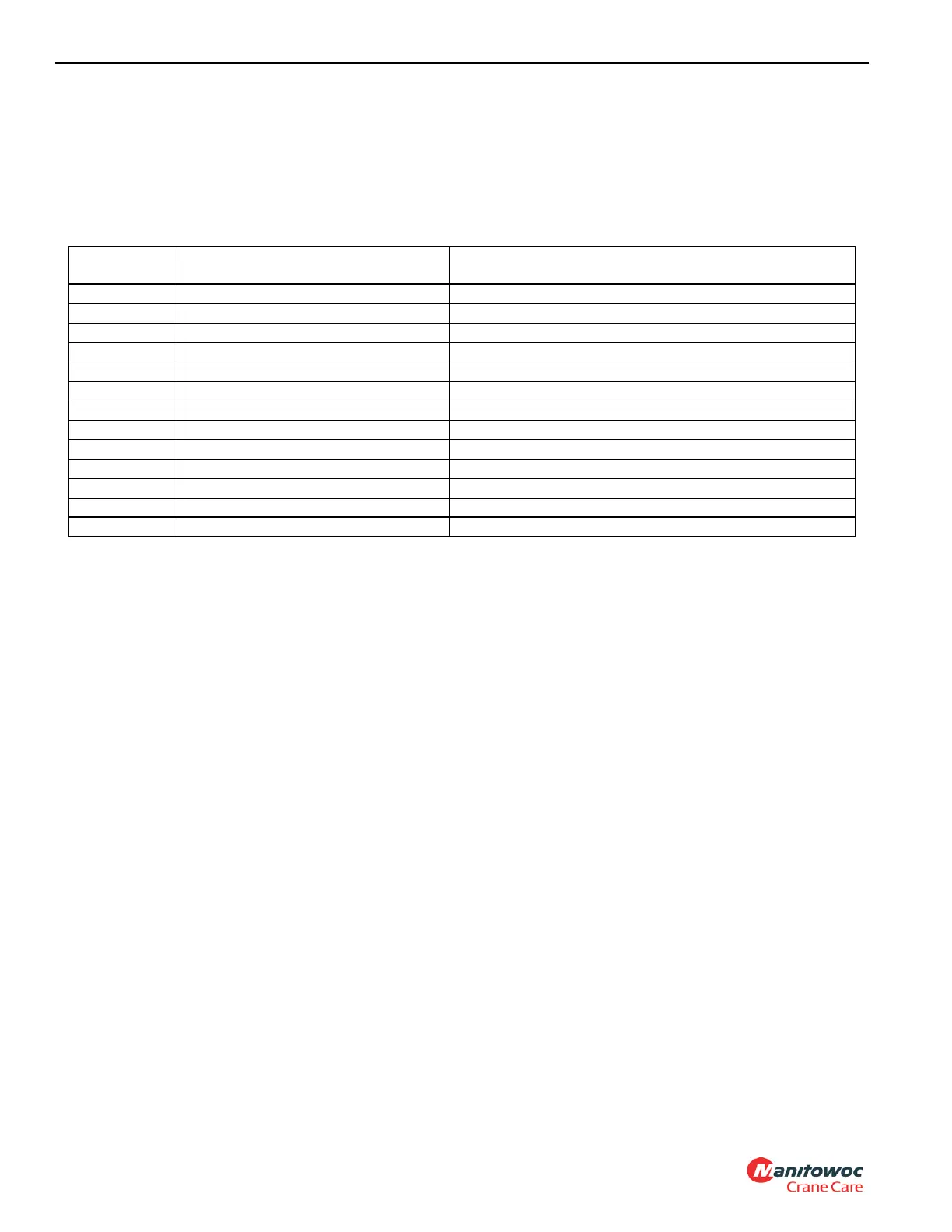

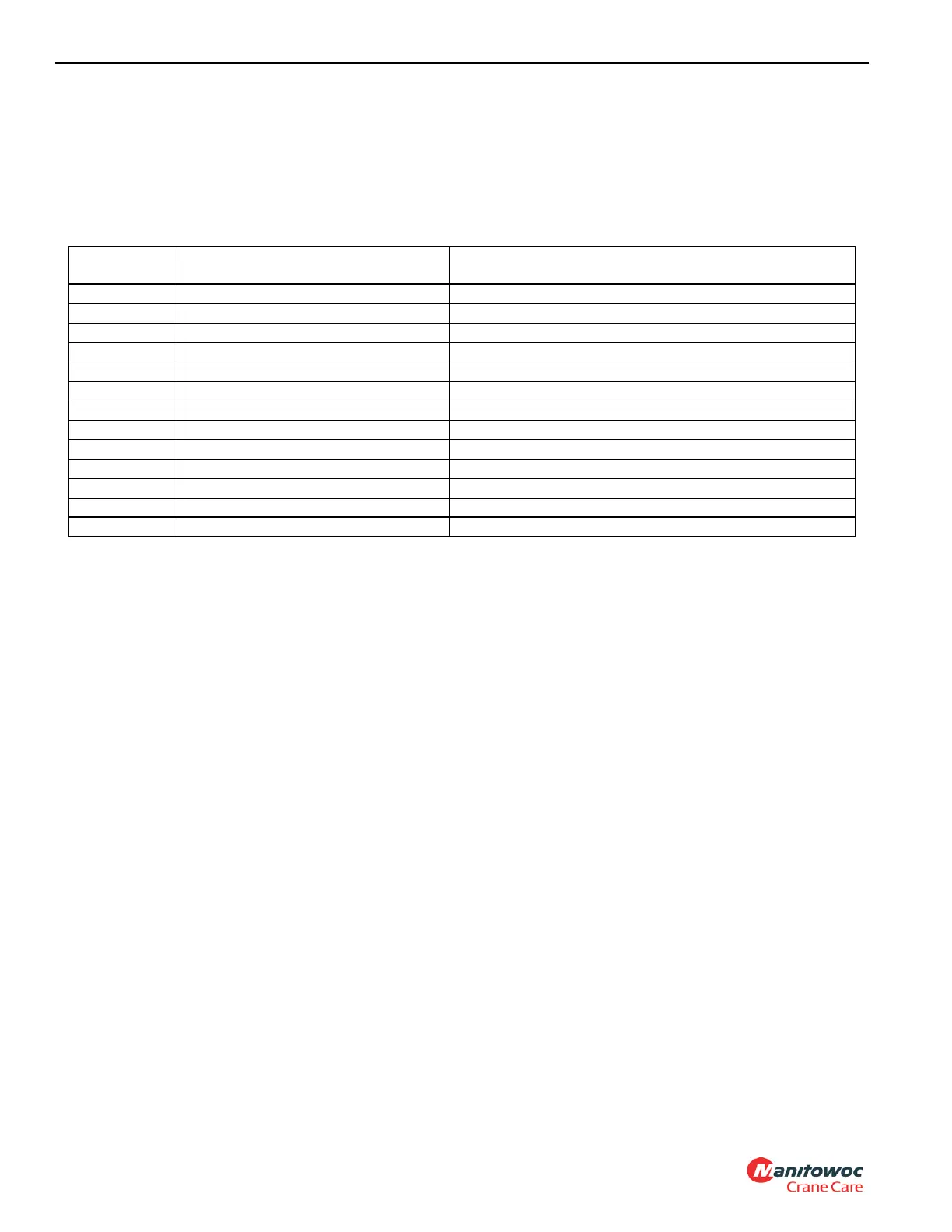

Table 6-2

Theory Of Operation

The hydraulic swivel allows oil to flow from the pumps to

various crane functions on the superstructure. All oil is

routed into the spool portion of the swivel where, through a

series of internally drilled passages, oil is transferred to

circumferential channels on the spool exterior. These

channels correspond with a mating port on the outer case of

the swivel. Each channel is separated by a series of nylon

and O-ring seals that prevent transfer of oil and pressure.

Return flow from the crane superstructure is accomplished in

the same manner through another set of ports.

Maintenance

Removal

1. Extend and set the outriggers. Ensure the crane is level

and the boom is over the front.

2. Elevate the boom and note at what boom angle, you

have the most clearance between the lift cylinder and

the turntable side plate. Shut down the engine.

3. Measure the distance from the top of the lift cylinder to

the base of the boom section where the lift cylinder

attaches. Cut two pieces of 4 x 4 in (10 x 10 cm) oak to

fit.

NOTE: It might be necessary to raise the boom slightly to

allow installation of the blocking.

NOTE: This blocking is to add extra support for the boom.

Any seepage or leakage in the holding valves or

internally in the cylinders will allow the boom to

settle over a period of time.

4. Use the oak blocking to block between the barrel of the

lift cylinder and the boom base section.

5. Tag and disconnect the hydraulic lines from the case of

the hydraulic swivel. Cap or plug all lines and openings.

6. Tag and disconnect the hydraulic lines and water lines

from the spool of the hydraulic swivel. Cap or plug all

lines and openings.

7. Tag and disconnect the water lines from the case of the

water swivel. Cap or plug all lines and openings.

8. Disconnect the swivel wiring harness connectors from

the carrier receptacles and the yellow ground wire from

the connector mounting bracket on the carrier frame. If

necessary, remove the electrical swivel. Refer to

Electrical Swivel, page 6-20.

NOTE: The hydraulic swivel weighs approximately 430 lb

(195 kg). The hydraulic, water, and electrical swivel

combined weigh approximately 520 lb (236 kg).

9. On the bottom of the swivel, bend the retainer tabs away

from the capscrew heads. Remove the eight capscrews

and four capscrew retainers securing the two retainer

plates to the spool. Remove the retainer plates from the

spool and the lugs on the carrier frame.

NOTE: It may be necessary to remove some drive line

components to remove the swivel.

Port #

Test Pressure

psi (kPa) (bar)

Function

1 500 (3400) (34) Dual Return

2 4000 (27500) (275) Hoist/Lift/Tele

3 4000 (27500) (275) Hoist/Lift/Tele

4 500 (3400) (34) Case Drain

5 4000 (27500) (275) Steer/Swing

6 2500 (17000) (170) Pilot, Swing Brake, Hose Reel

7 4000 (27500) (275) Front- Steer Left

8 4000 (27500) (275) Front- Steer Right

9 2500 (17000) (170) Brakes/Air Conditioning

10 2500 (17000) (170) Brakes, Front

11 2500 (17000) (170) Brakes, Rear

A ----- Heater Supply (Coolant)

B ----- Heater Return (Coolant)

Loading...

Loading...