2-52 Published 11-22-2016, Control # 345-12

HYDRAULIC SYSTEM RT9130E-2 SERVICE MANUAL

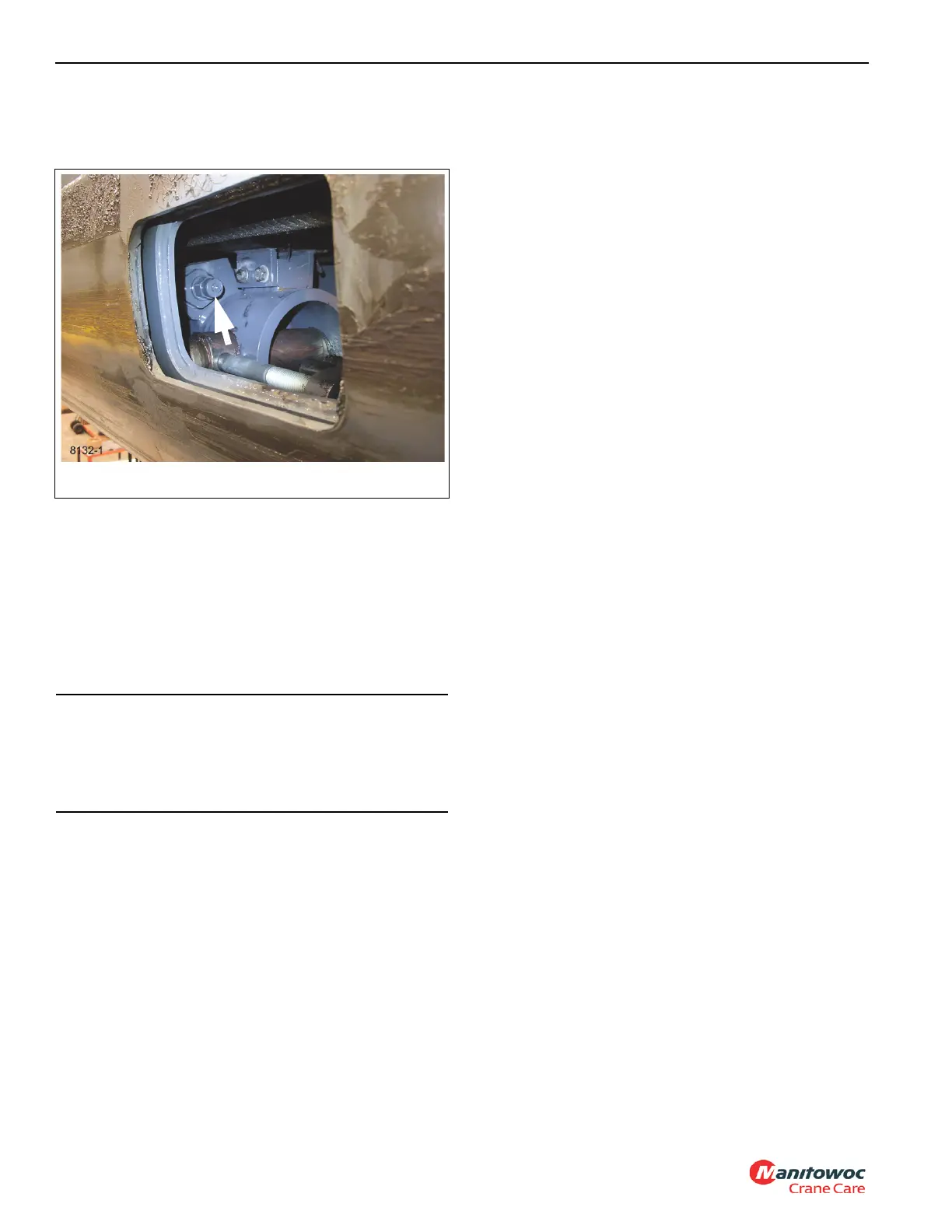

4. From the access holes in the opposite side of the boom,

relieve the pressure in the lower telescope cylinder by

loosening the bleed plug.

5. Unscrew holding valve from its port block. (See

Figure 2-31.)

Installation

1. Check the inside of the port block for any sharp edges or

burrs and remove as necessary with emery cloth.

2. Install new O-rings onto the holding valve.

3. Lubricate the holding valve and O-rings with clean

hydraulic oil.

NOTE: The holding valve should turn by hand until

compression of the O-rings begins.

4. Carefully install the holding valve into the port block until

fully seated.

5. Remove the telescope hold valve tool.

6. Test the check valve and port block by operating the

telescope cylinder. Verify telescope cylinder works

without problems; verify there is no leaking. Make

repairs as needed.

SHUTTLE VALVE

Description

The in-lined plumbed shuttle valve is used as a directional

selector valve. It is located at the inlet of the telescope rod

drain solenoid valve. It is used to direct the higher trapped

pressure of the rod side telescope cylinders to the telescope

rod drain solenoid valve inlet.

It consists of a ball that moves between two opposing check

seats. When one port is pressurized, the ball is forced

against the opposite seat, blocking that inlet and providing a

flow path to the outlet port.

Maintenance

Removal

1. Tag and disconnect hydraulic lines from valve and cap or

plug all openings, and remove valve.

Installation

1. Connect the hydraulic lines as tagged during removal.

2. Check valve and hydraulic connections for leaks. Make

repairs as needed.

CAUTION

Do not damage the O-rings during installation of the

holding valve. If the holding valve turns freely then gets

hard to turn, then easy to turn; remove the holding valve

and check the O-rings. They have probably been

damaged by a sharp edge of a port.

Loading...

Loading...