7-4 Published 11-22-2016, Control # 345-12

POWER TRAIN RT9130E-2 SERVICE MANUAL

23. Connect the air filter tubing at the engine and the air

filter. Insure the inside of all tubing and connectors is

clean.

24. Service the transmission, engine lubrication system, and

engine cooling system.

25. Start the engine. Check all hoses and fittings for leaks.

Recheck all fluid levels. Refer to Lubrication, page 9-1.

Engine Drive Belts

The proper operation of engine belt-driven components such

as the alternator, fan, and water pump depend on the proper

condition and tension of the engine drive belt.

NOTE: Belt tension is maintained with an automatic belt

tension device.

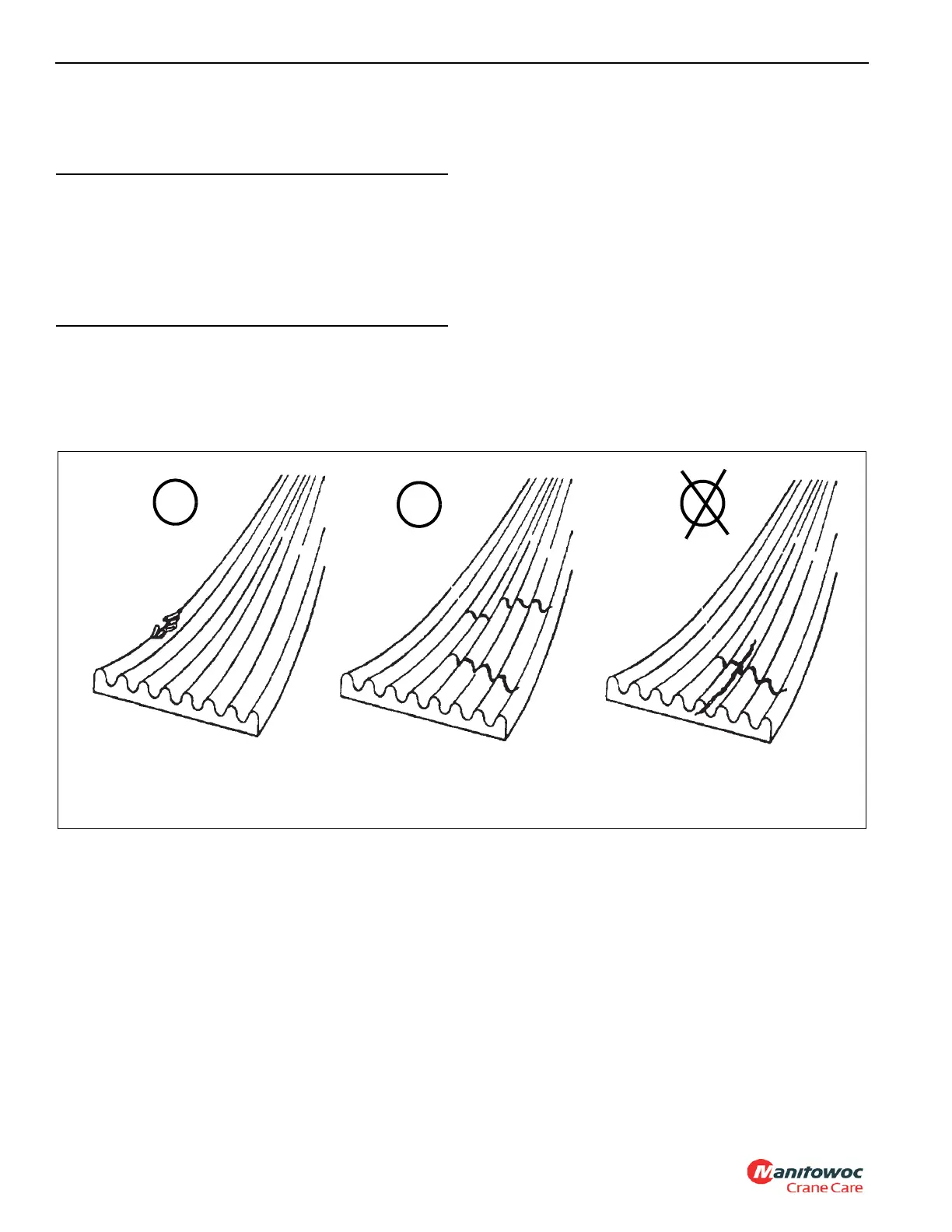

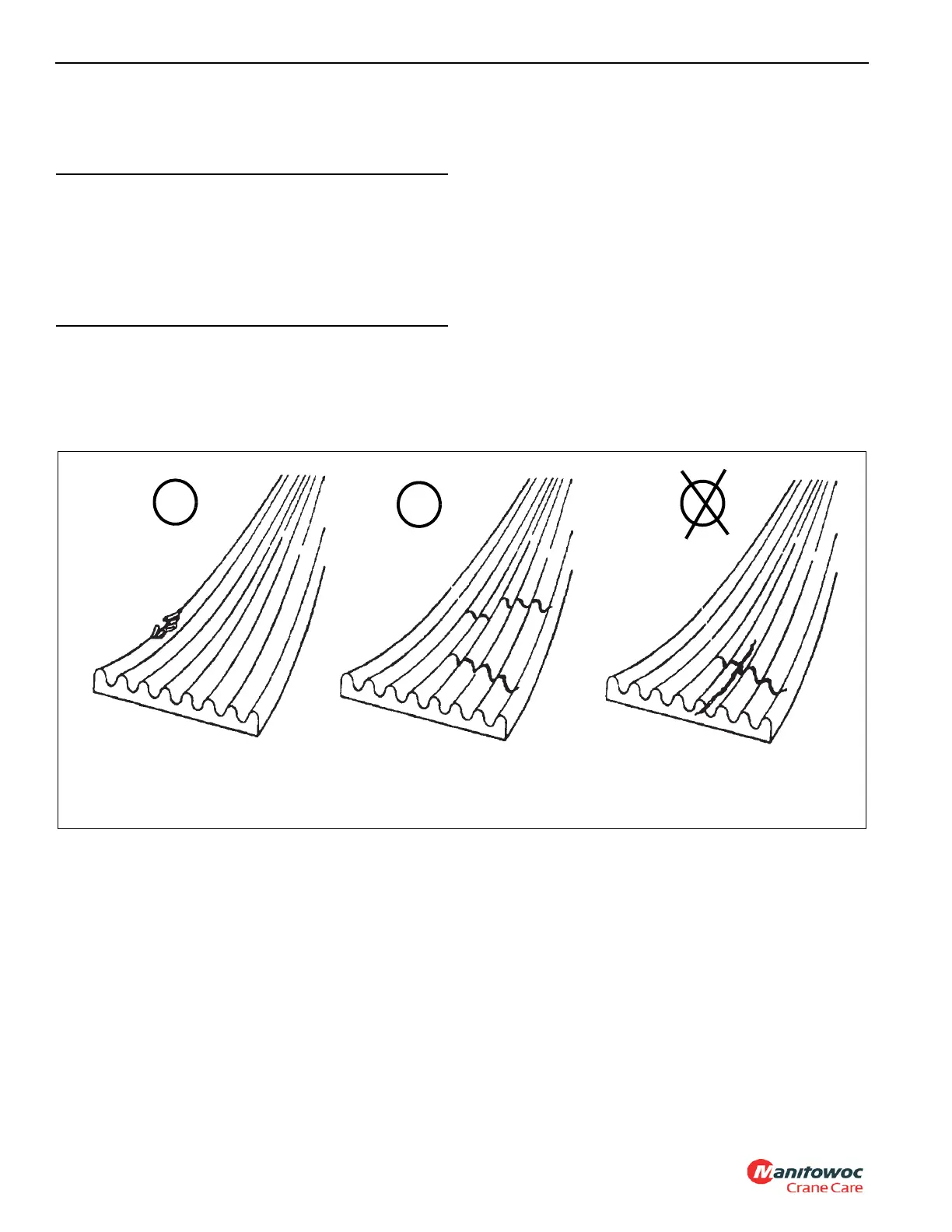

The engine drive belt (Figure 7-1) should be inspected

visually on a daily basis. The drive belt should be inspected

for cracks, frayed areas, and glazed or shiny surfaces. A

drive belt that is glazed or shiny indicates belt slippage.

Engine drive belt damage can be caused by various factors

such as incorrect tension, incorrect belt size, misaligned

engine pulleys, incorrectly installed belt, or by oil, grease, or

hydraulic fluid on the belt.

Refer to the engine manufacturer’s manual for any special

tools or belt tension specification.

CAUTION

Equipment Damage Hazard!

The cleanliness of the Air Intake and Charge-Air-Cooling

system is critical to engine durability since any

contamination will be ingested directly into the engine

cylinders and passed through the turbocharger machinery

and may result in serious engine damage.

FIGURE 7-1

Missing Material

Traverse Cracks

Longitudinal Cracks Intersecting with Transverse

Cracks must be Replaced

OK

OK

OK

Loading...

Loading...