Grove Published 11-22-2016, Control # 345-12 8-13

RT9130E-2 SERVICE MANUAL UNDERCARRIAGE

Maintenance

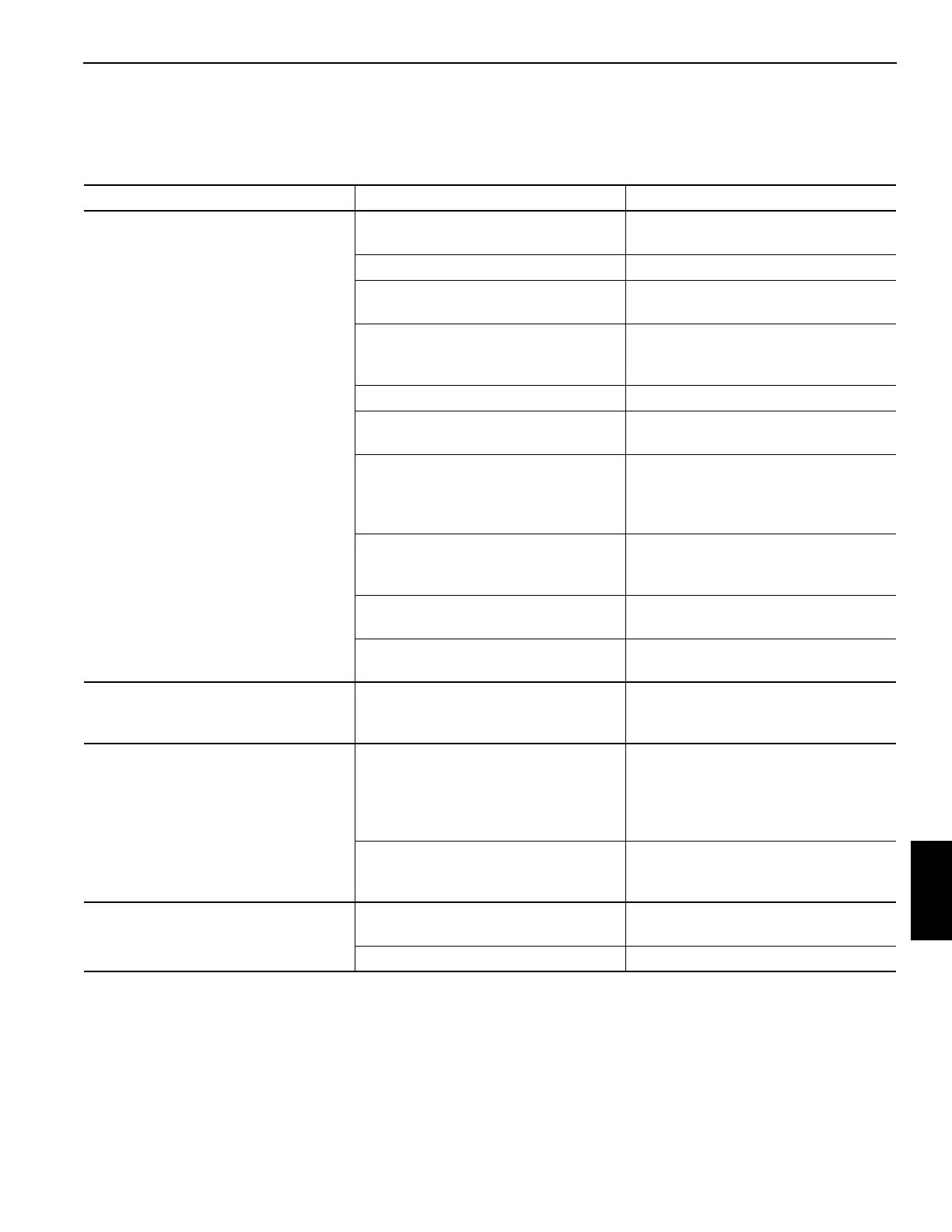

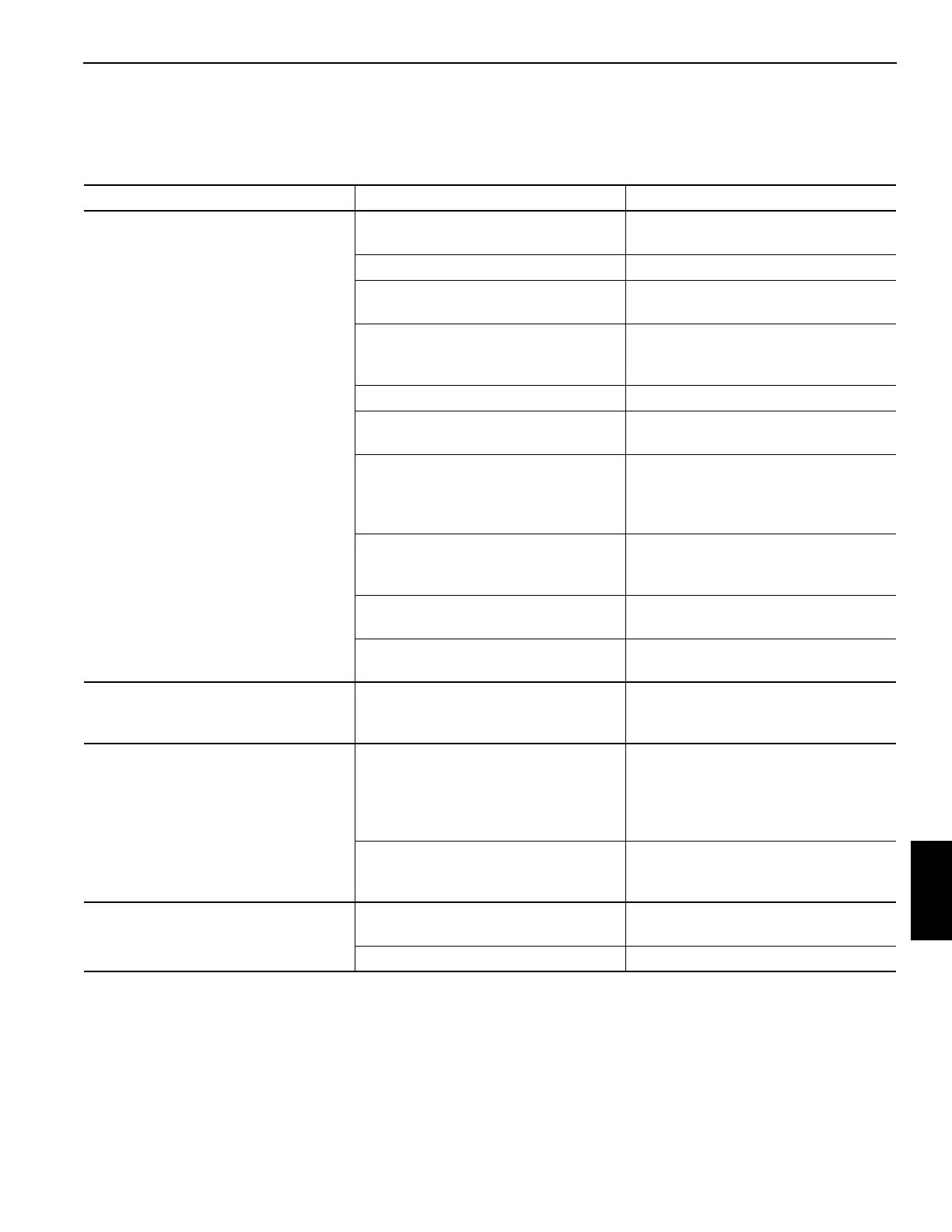

Troubleshooting

Table 8-3

General

A schedule for the periodic adjustment, cleaning, inspection,

and lubrication of brake equipment should be established by

the operator on the basis of past experience and severity of

operation.

The disc brakes are not adjustable. Brakes should be

cleaned, inspected, and linkage lubricated periodically to

assure maximum performance.

Symptom Probable Cause Solution

1. Brakes are poor. a. Lining thickness less than

0.125 in (3mm).

a. Replace lining.

b. Brake pedal operation. b. Free mechanical linkage.

c. Restriction or leaks in lines. c. Check all lines for leaks and

restrictions.

d. Low hydraulic oil flow. d. Check the hydraulic oil level in

reservoir and check flow from

the tandem brake valve.

e. Air in brake lines. e. Bleed the brakes.

f. Brake pads/linings are

grease-soaked.

f. Replace pads/linings.

g. Engine not running. g. Start engine. Due to the

operation, the engine must be

running to provide full brake

power.

h. Brake relief valve stuck open. h. Replace the relief valve. Refer

to your Manitowoc Crane

Care Parts Manual.

i. Dual accumulator charge

valve not charging

i. Check valve operation and

repair or replace valve.

j. Accumulators not pre-

charged.

j. Check accumulator pre-

charge.

2. Hard brake pedal with engine

running.

a. Pedal travel being interfered

with.

a. Check all pedal linkage and

ensure it is free and adjusted

properly.

3. Brakes lock up. a. Too much hydraulic flow. a. Check the flow from the flow

divider. Too much flow will

cause the brakes to be

applied by the oil trapped in

the power boost chamber.

b. Brake pedal push rod

improperly adjusted, causing

brakes to be always applied.

b. Adjust the push rod linkage so

the brake pedal and push rod

fully return.

4. Uneven braking or pad wear. a. Lining thickness less than

0.125 in (3 mm).

a. Replace the lining.

b. Grease on the pads/linings. b. Replace the pads/linings.

Loading...

Loading...