Manitowoc Published 11-22-17, Control # 257-02 5-51

MLC300 SERVICE/MAINTENANCE MANUAL HOISTS

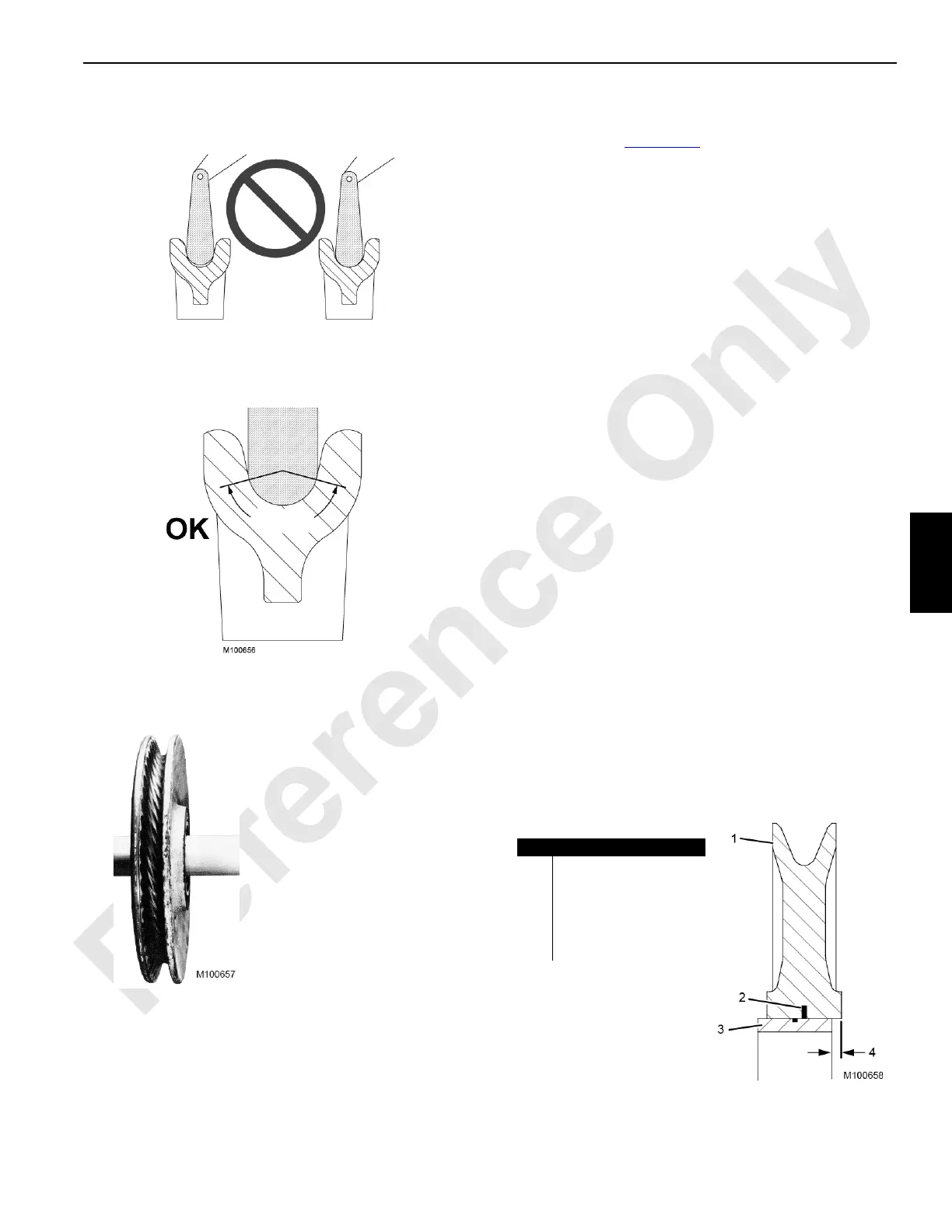

• Inspect the nylon sheaves to verify they have not

separated and “walked off” the steel inserts or the

bearings (see Figure 5-32

).

Maximum sideways displacement is 3 mm (1/8 in).

Replace worn or damaged sheaves.

NOTE: Nylon sheaves have the following characteristics:

• Depending on the type of wire rope used, it is

normal for nylon sheaves to show the wire

rope print. Do not remachine the nylon

sheaves.

• Nylon sheaves cannot be accurately inspected

using conventional methods such as sheave

gauges.

• Due to the characteristics of nylon sheaves,

the nylon material will actually move to better

support the wire rope as the sheave wears

normally.

• Nylon sheave properties will be degraded in

temperatures above 60°C (140°F).

NOTE: Many current production sheaves are not equipped

with grease fittings, but are packed with grease at

assembly. Repack the bearings of these sheaves

with CraneLUBE EP #2 grease when the sheaves

are overhauled.

Due to application and design variations, it is not

possible to give specific grease repacking intervals

or the life expectancy of the components.

• Make sure the sheaves, drums, and rollers are properly

lubricated according to the instructions in the lubrication

guide provided with this manual.

NOTE: For some sheaves, the seals are an integral part of

the bearing. Therefore, if a seal is damaged during

repacking, the complete bearing may need to be

replaced.

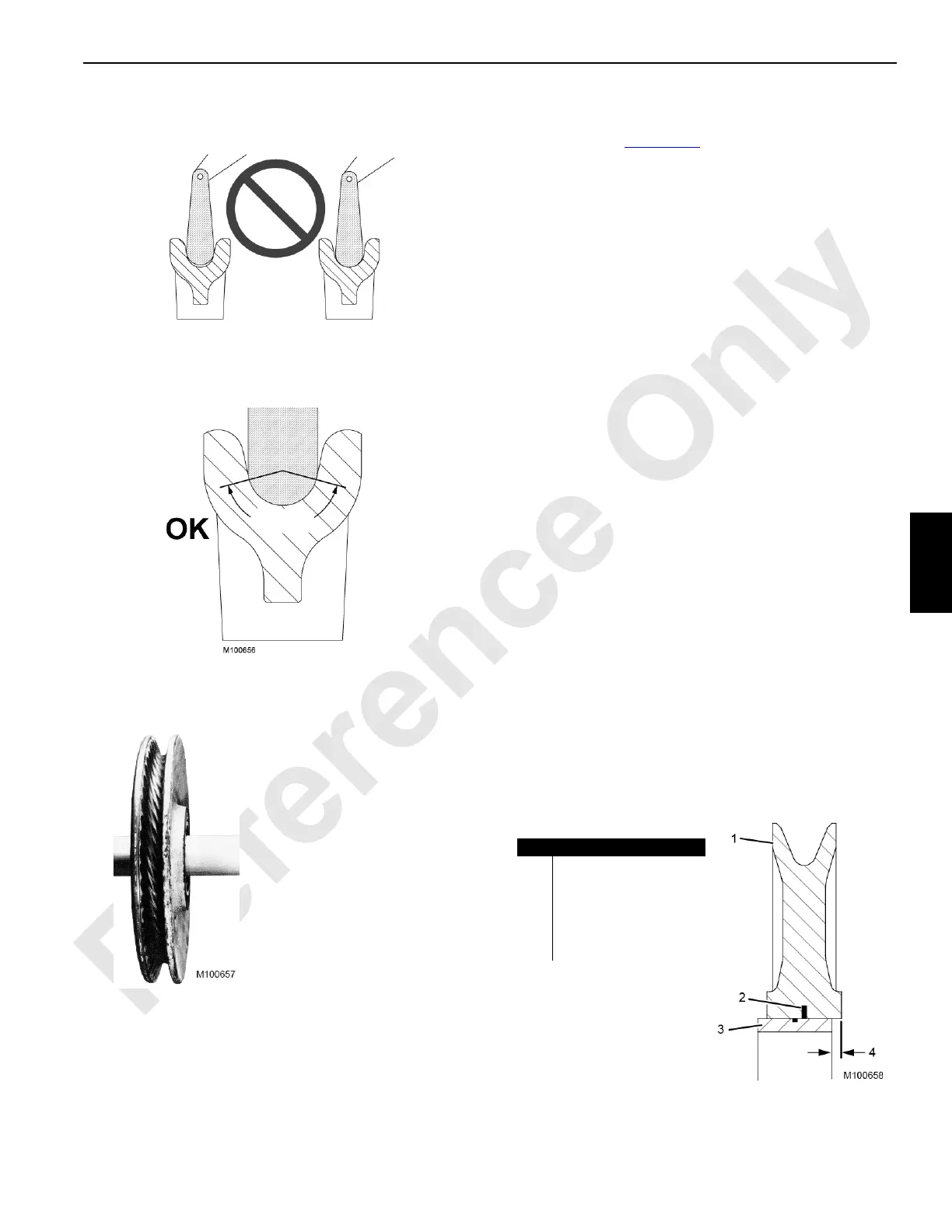

Observe the groove to see if the contour of the gauge

matches

the contour at the bottom of the sheave groove.

Proper fitting sheave groove should support

the

wire rope or 135–150° of rope circumference.

Groove Too Small

Groove Too Large

FIGURE 5-30

“Corrugated” steel sheave,

roller, or drum will cause

the

wire rope to wear rapidly.

FIGURE 5-31

Item Description

1 Nylon Sheave

2 Improper Snap Ring

Engagement

3 Steel Insert of Bearing

4 1/8 in (3 mm) Maximum

Sideways Displacement

FIGURE 5-32

Loading...

Loading...