SETUP AND INSTALLATION MLC300 OPERATOR MANUAL

4-10

Published 11-20-19, Control # 234-19

PIN AND CONNECTING HOLE

CLEANLINESS

To prevent dirt from damaging closely machined surfaces of

pins and connecting holes:

• Thoroughly clean all pins and connecting holes.

• Apply a light coat of grease to all pins and connecting

holes.

HOSE AND CABLE CLEANLINESS

To prevent dirt from entering the hydraulic systems or from

damaging the electric connectors:

• Thoroughly clean the hydraulic fittings and the electric

connectors before connecting them.

• Thoroughly clean the dust caps before attaching them to

hoses, tubes, or cables.

• Do not drag the hydraulic hose fittings, the hydraulic

hoses, the electric cable connectors, or the electric

cables on the ground.

NOTE Apply a light coat of silicone lubricant to the threads

of all dust caps, couplers, and connectors to help in

preventing the threads from seizing.

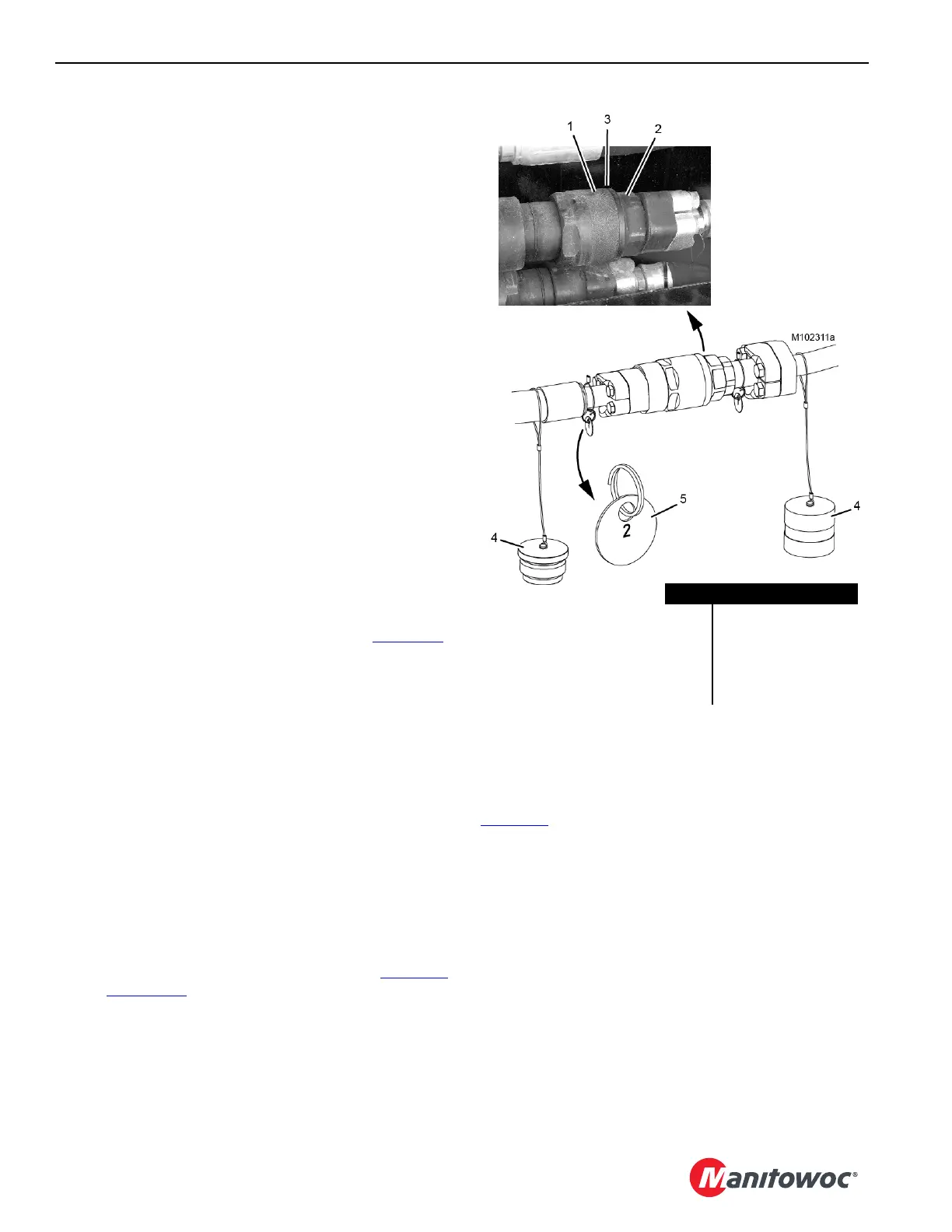

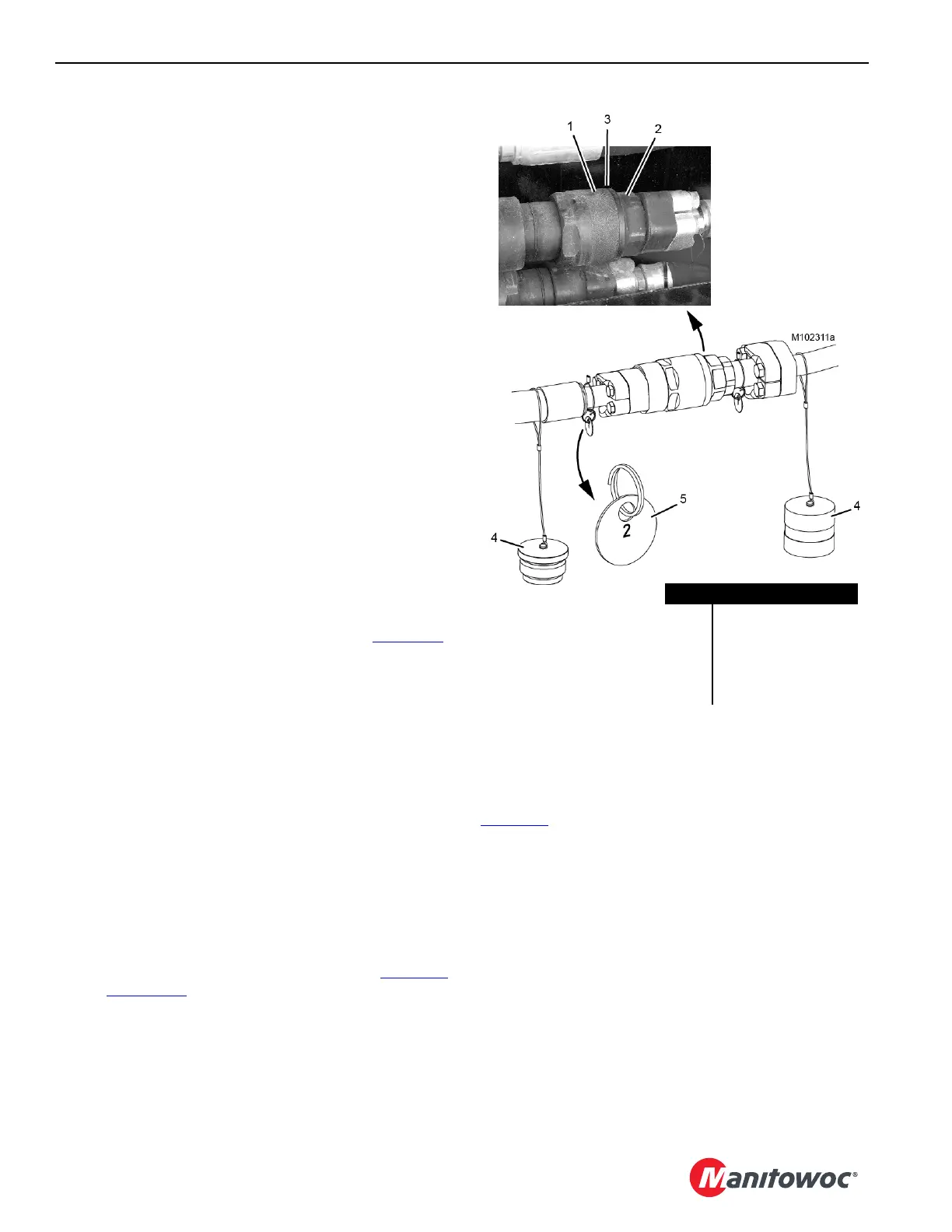

HYDRAULIC HOSE IDENTIFICATION

Where necessary, the hydraulic hoses and corresponding

couplers have identification tags as shown in Figure 4-8

.

Match the number on the hose with the number on the

corresponding coupler to ensure proper connection.

CONNECTING/DISCONNECTING

HYDRAULIC HOSES AND ELECTRIC

CABLES

Always STOP ENGINE before performing the following

steps during crane assembly and disassembly:

• Connecting and disconnecting hydraulic lines. It will be

easier to connect and disconnect the couplers when

there is no pressure in the system.

• Connecting and disconnecting electric cables. The

potential for operating faults or damage to the electric

components exists if the engine is not stopped.

NOTE To stop the engine if it was started from the remote

control, turn the external engine switch (8, Figure 4-7

on page 4-8) COUNTERCLOCKWISE to the STOP

position.

To stop the engine if it was started from the cab, use

the ignition switch in the cab.

TIGHTENING HYDRAULIC COUPLERS

Connect each screw-to-connect coupler and nipple

(Figure 4-8

) as follows:

1. Lubricate coupler (1) threads, nipple (2) threads, and

nipple O-ring (3) with LPS-2 Aerosol Lubricant.

2. Hand tighten coupler (1) onto nipple (2).

3. Using opened-end wrenches, tighten the coupler until

there is metal-to-metal contact between the coupler and

the nipple. O-ring (3) must not be visible.

To avoid damage, do not exceed a torque of:

• Size -06 = 1.62 lbf ft (2,2 Nm)

• Size -08 = 1.33 lbf ft (1,8 Nm)

• Size -12 = 4.13 lbf ft (5,6 Nm)

• Size -20 = 6.04 lbf ft (8,2 Nm)

• Size -24 = 19.16 lbf ft (26,0 Nm)

Figure 4-8

Item Description

1 Coupler

2 Nipple

3 O-ring (not visible)

4Dust Cap

5 Identification Tag

Loading...

Loading...