Manitowoc Published 11-20-19, Control # 234-19 4-73

MLC300 OPERATOR MANUAL SETUP AND INSTALLATION

Install Counterweight Boxes

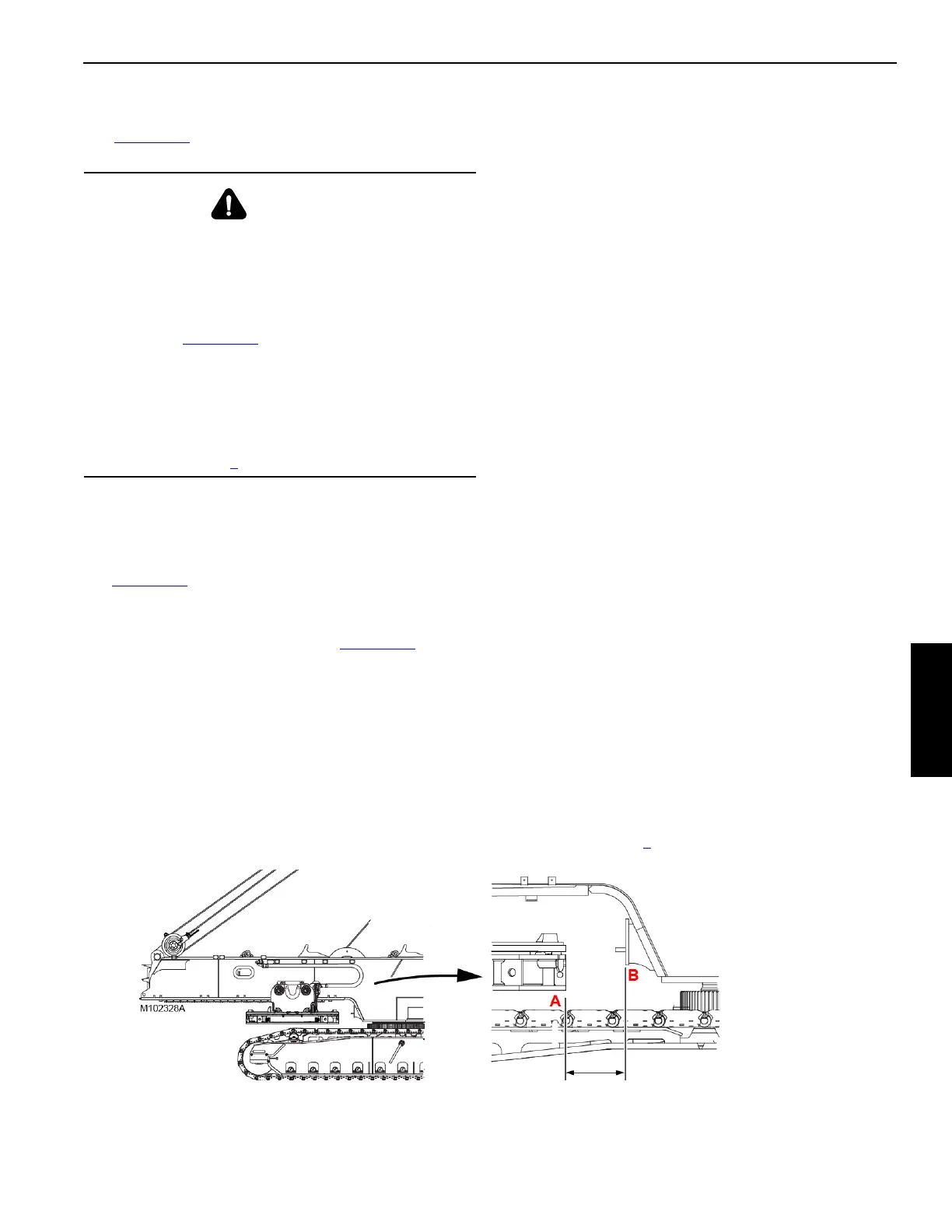

See Figure 4-52 for the following procedure.

NOTE The counterweight boxes (2) must be installed with

an assist crane.

1. Travel the VPC trolley forward using the switch on the

remote control until the distance from the front edge (A,

Figure 4-53

) of the counterweight tray to the edge (B) of

the rotating bed is no more than the dimension given.

2. Install the desired number of counterweight boxes (see

Counterweight Series table in Figure 4-52

) in the

following sequence:

a. One counterweight box installed on either side of

the tray.

b. Two counterweight boxes installed on the other side

of the tray.

c. Continue installing the counterweight boxes in an

alternating sequence, two boxes at a time.

d. Finally, install one counterweight box on the

required side so that both stacks have an equal

number of boxes.

Note that a difference of not more than one counter-

weight box must be maintained side-to-side during

disassembly

3. Attach synthetic lifting slings (3, View E) around the

lifting lugs (4) on the counterweight boxes (2). Two

boxes may be lifted at one time.

4. Boom, swing, and hoist as necessary to position the

counterweight boxes on the desired side of

counterweight tray.

5. Lower the boxes so that the alignment lug (5, View F) on

the tray or box engages the notch on the adjacent box.

6. Disconnect the lifting slings.

7. Repeat the steps until the required number of boxes are

installed.

8. When all boxes have been installed, secure them as

follows:

a. Wrap the counterweight chain assembly (7, View B)

around the lifting lugs (4) on the counterweight

boxes and the counterweight tray lug (8).

The counterweight chain assemblies are designed

to minimize counterweight movement during travel

and operation permitted by Manitowoc’s operating

instructions.

b. Adjust the position of the chain so the turnbuckle (9,

View B) handle is accessible between two lifting

lugs (4).

c. Pull the chain tight by hand and attach the free end

of the chain to the connector (10, View C).

d. Tighten the turnbuckle until the counterweight chain

assembly is snug.

NOTE The ratchet on the turnbuckle must be flipped in one

direction to tighten the turnbuckle and in the opposite

direction to loosen the turnbuckle.

e. Secure the excess chain with the safety pin (11,

View D).

f. Repeat step 8

at the remaining three locations.

WARNING

Crush Hazard!

To prevent the crane from tipping and the counterweight

boxes from falling off the tray during assembly:

• Do not install (or remove) the counterweight boxes

until the counterweight tray is traveled to the position

shown in Figure 4-53

. The crane will tip.

To prevent the counterweight boxes from falling and

crushing personnel:

• Do not lift more than two boxes at a time. The lifting

lugs may break resulting in the boxes falling.

• Install the counterweight boxes in the sequence

specified in step 2

of this procedure.

Figure 4-53

Not More Than

375 mm (14-3/4 in

Loading...

Loading...