Manitowoc Published 11-20-19, Control # 234-19 3-5

MLC300 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

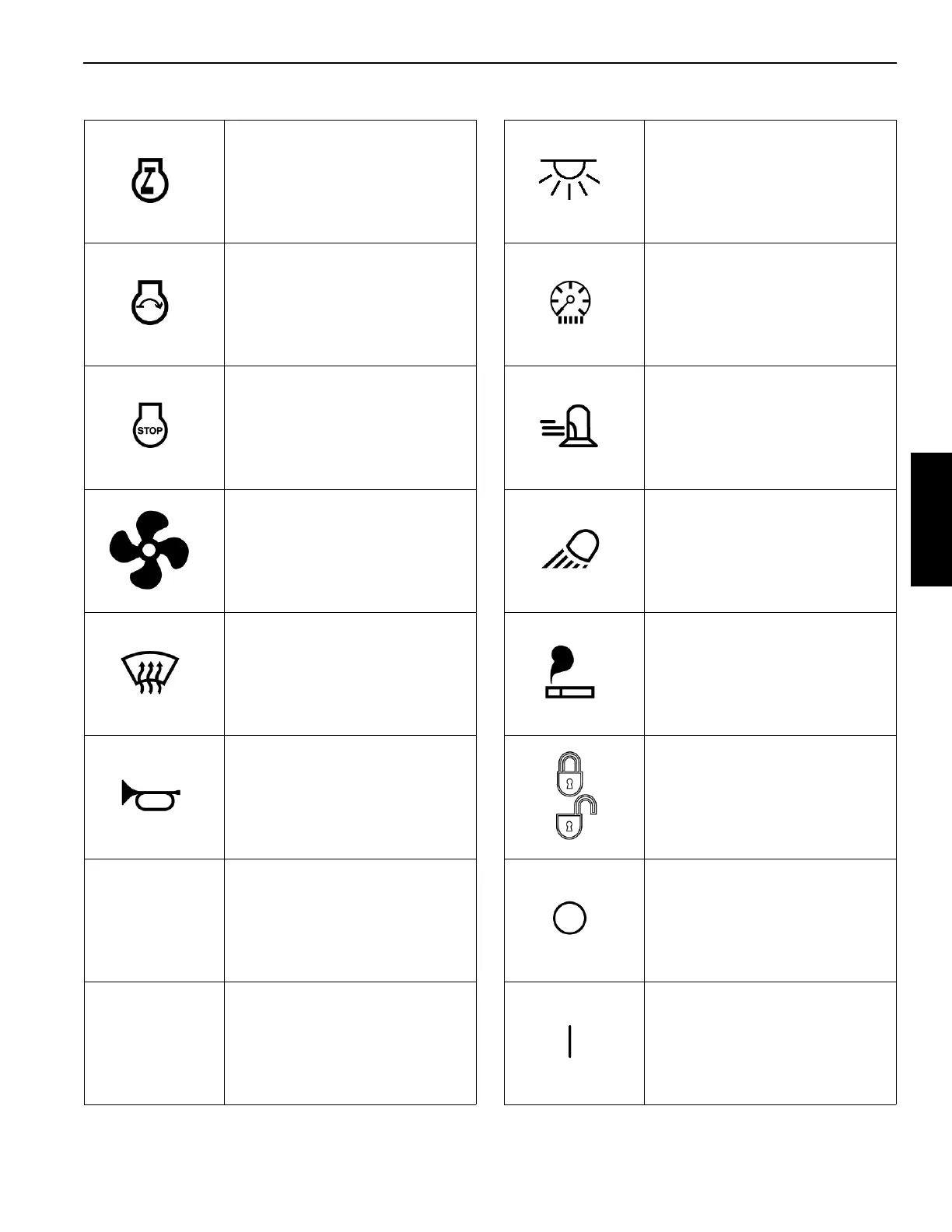

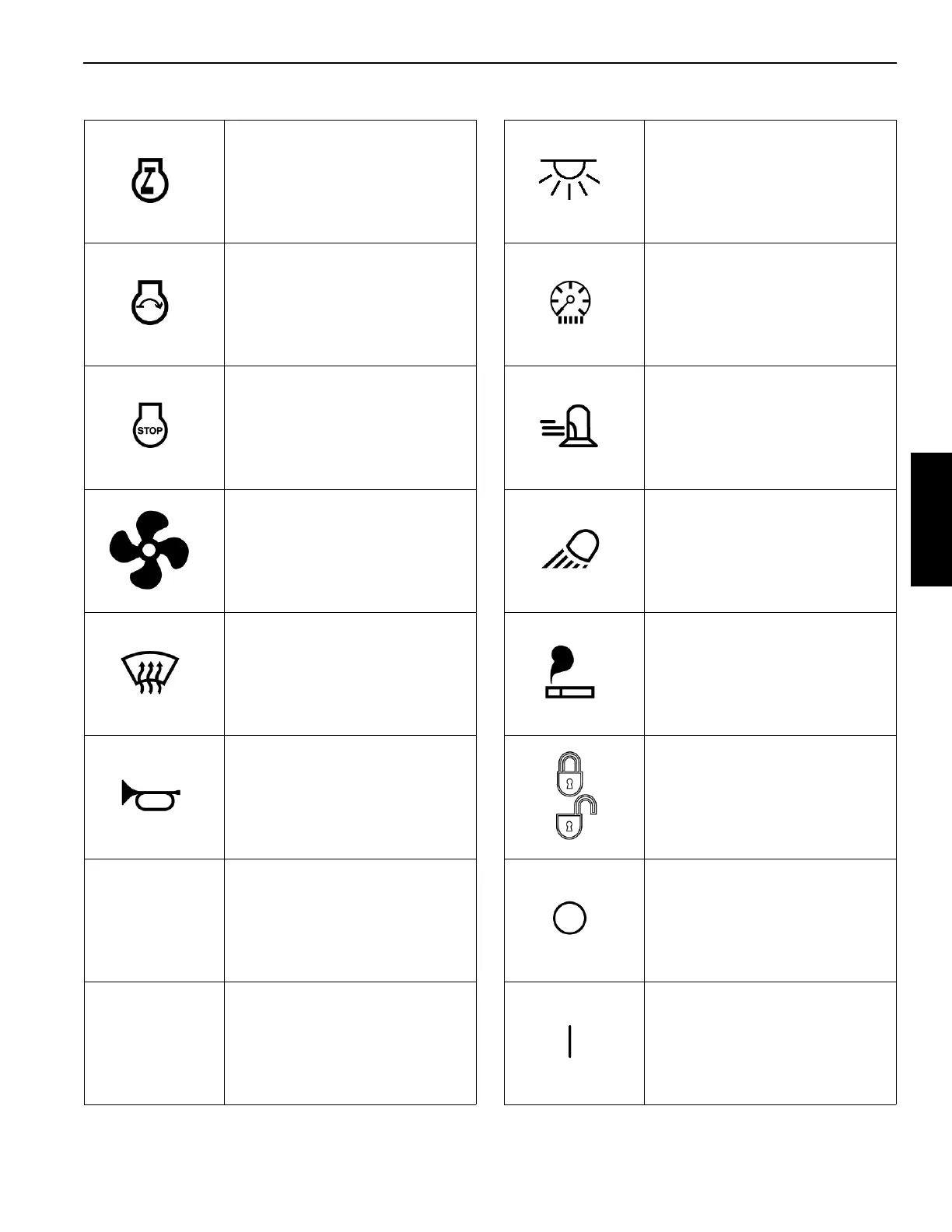

Engine Run Light, Dome

Engine Start Light, Consoles

Engine Stop Light, Position

Fan Light, Work (and camera)

Heater Lighter

Horn

Lock and

Unlock

Off

On

Table 3-2. Symbol Identification — Control Consoles

Loading...

Loading...