National Crane 01-22-2019 Control # 051-08 7-3

1300A OUTRIGGERS

4. Tag and remove the hydraulic hoses connected to the

extension cylinder (Figure 7-7).

5. Remove the extension cylinder bolts (Figure 7-7) and

lower the base of the extension cylinder to the bottom of

the outrigger box. See next step for later versions of

outrigger box.

NOTE: Place a piece of wood under the cylinder so that

the cylinder can be lowered to the bottom of the

outrigger box.

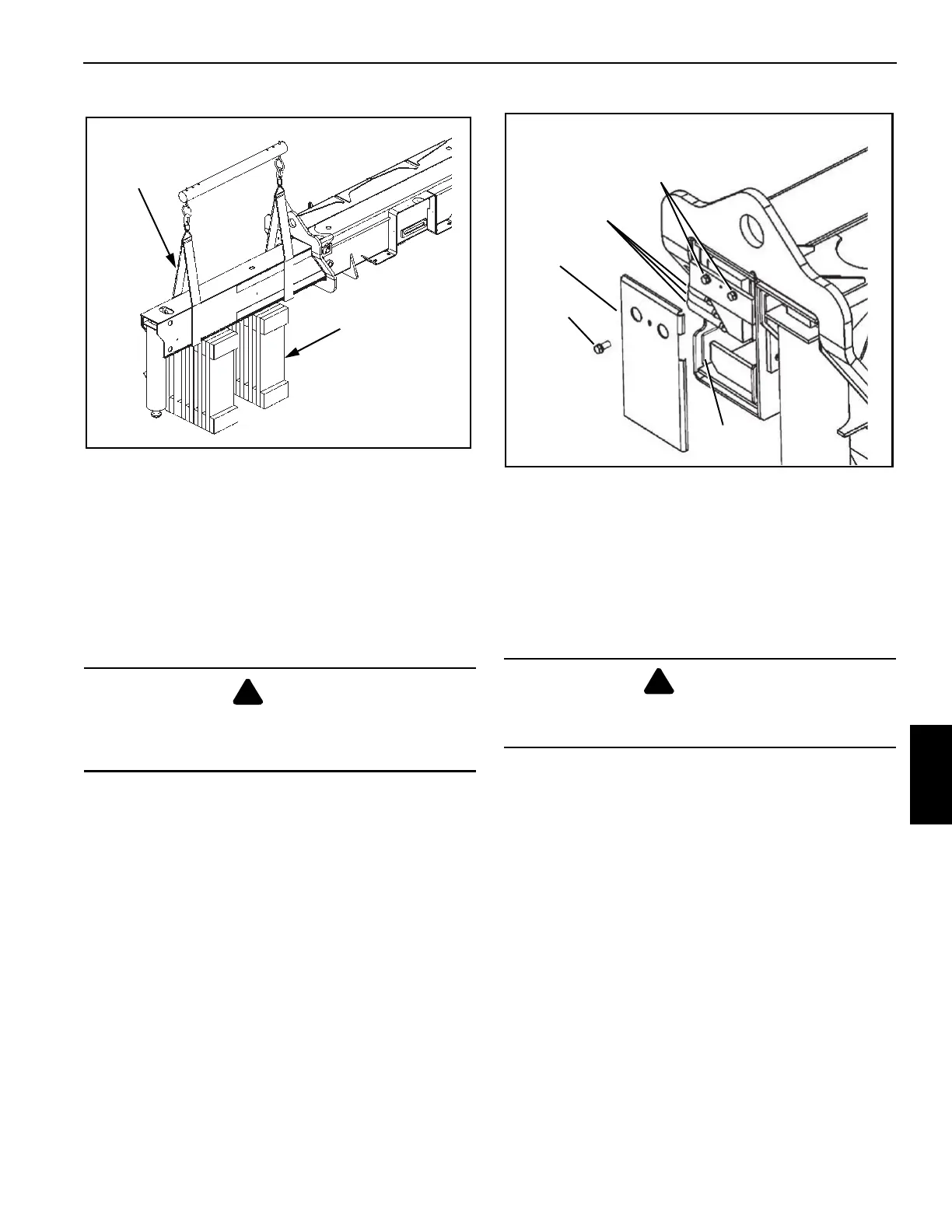

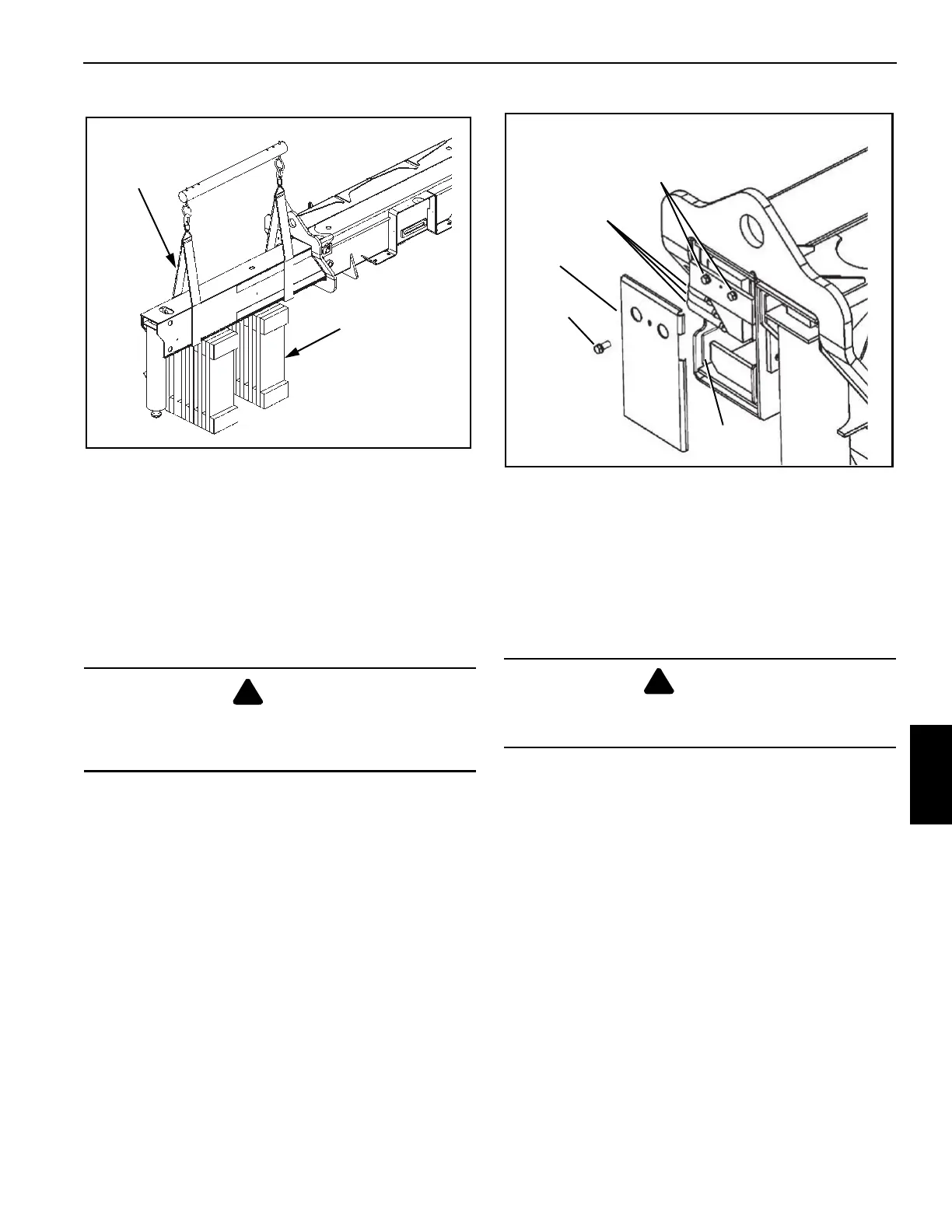

6. Later versions of the outrigger box have a removable

end plate (Figure 7-3) to provide access to the extension

cylinder. Remove the end plate.

7. Cranes equipped with the Outrigger Monitoring System

will have a string potentiometer attached to the inside of

the end plate. Remove string potentiometer using the

procedures under String Potentiometer, page 7-7.

8. Unbolt the cylinder and lower it to the bottom of the

outrigger box.

9. Remove the wear pad set screws in the top of the

outrigger beam and back off the top wear pads (7)

(Figure 7-1). Access is through the access hole in the

end of the outrigger box (5) (Figure 7-1).

10. Remove the wear pad set screws on the side of the

outrigger beam and back off the side wear pads (8).

11. Place blocking material under the outrigger beam

(Figure 7-2).

12. Pull the outrigger beam out of the outrigger box with the

lifting device.

13. Position the outrigger beam on the blocking material.

Inspection

Inspect the outrigger beam for bends, evidence of cracks, or

other damage. Check the outrigger beam internally for

hydraulic fluid, which may indicate a leaking cylinder, loose

connection, or damaged hydraulic line.

Installation

1. Apply grease (EP-MPG) to the bottom of the outrigger

beam.

2. Screw the bottom wear pads on the outrigger box in until

about 0.25 in (6.4 mm) is protruding. This keeps the

beam off of the bottom of the outrigger box.

3. Slide the beam into the outrigger housing.

DANGER

Keep hands out of the access hole when removing the

extension cylinder bolts. The barrel is free to drop when

the bolts are removed and cause personnel injury.

Blocking material

must be capable of

supporting the

outrigger beam.

Use lifting

straps. Do not

use chains.

FIGURE 7-2

DANGER

Blocking material must be able to support the outrigger

beam and not allow the beam to tilt or slide.

FIGURE 7-3

Extension Cylinder

Hydraulic Hoses

Extension

Cylinder Bolts

Nonadjustable

Wear Pad

End Plate

End Plate

Bolt

Loading...

Loading...