National Crane 01-22-2019 Control # 051-08 9-5

1300A CRANE INSTALLATION

• A single front outrigger (SFO) is not necessary for 360°

stability if the mounting dimensions are maintained and

minimum rear axle and maximum front axle weights are

not exceeded.

NOTE:

• For smooth crane operation, a variable speed governor

and energize-to-run fuel solenoid on diesel tuck engines

are required. Electronic fuel injection is also required.

• All mounting data is based on a National Series 1300A

subbase and an 85 percent stability factor.

• The complete unit must be installed in accordance with

factory requirements, and a test performed to determine

actual stability and counterweight requirements. Contact

the factory for details.

• Transmission neutral safety interlock switch is required.

PTO REQUIREMENTS

Horsepower

A three section hydraulic gear pump is furnished with this

crane. The pump supplies 34 GPM (129 LPM) to the hoist,

29 GPM (98 LPM) to the boom, and telescope and 14 GPM

(53 LPM) to the turn and outriggers circuit. To provide these

flows, the pump shaft must turn at 1800 RPM. The PTO

requirement is a torque rating of at least 400 ft-lb (542 N·m)

or 76 HP (56.6 kW) per 1000 RPM of PTO shaft speed.

Direct PTO Mount

In most installations the pump can be mounted directly to the

PTO using adapter assemblies available from the PTO

supplier. If the pump is direct mounted, its weight should be

supported by a strap between the pump and the

transmission. The splined shaft coupling in a direct mount

pump installation requires lubrication. #200S Silver Streak

Special Multi-Lube (Medium) is applied to the shaft during

original installation and reapplied to the shaft or zerk

provided on PTO housing shaft semi-annually thereafter.

PTO Ratio

Pump shaft speed is determined by truck engine RPM and

PTO ratio:

Pump Shaft Speed = Truck Engine RPM x PTO Ratio

The following PTO ratio and engine speed combinations

provide proper pump shaft speed which is the recommended

maximum speed for the

1300A pump.

The speeds shown below are optimum operating speeds.

The engine must be operated at a speed such that the

horsepower developed is adequate to run the pump under

pressure and provide the required flow.

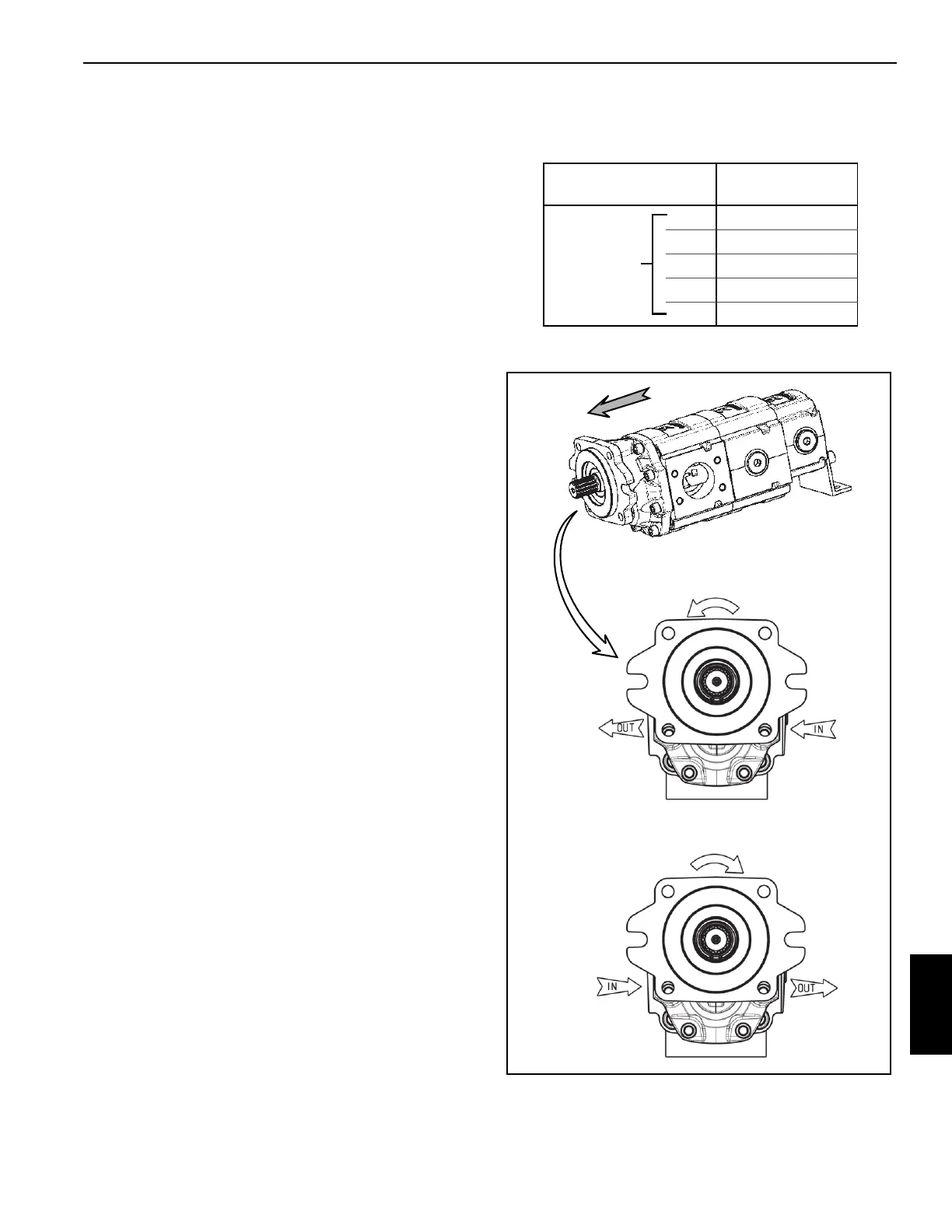

ENGINE SPEED

(RPM)

PTO RATIO

1800 RPM PUMP

2200 82%

2000 90%

1800 100%

1600 113%

1500 120%

Diesel

Engine

Optimum

Speed

Range

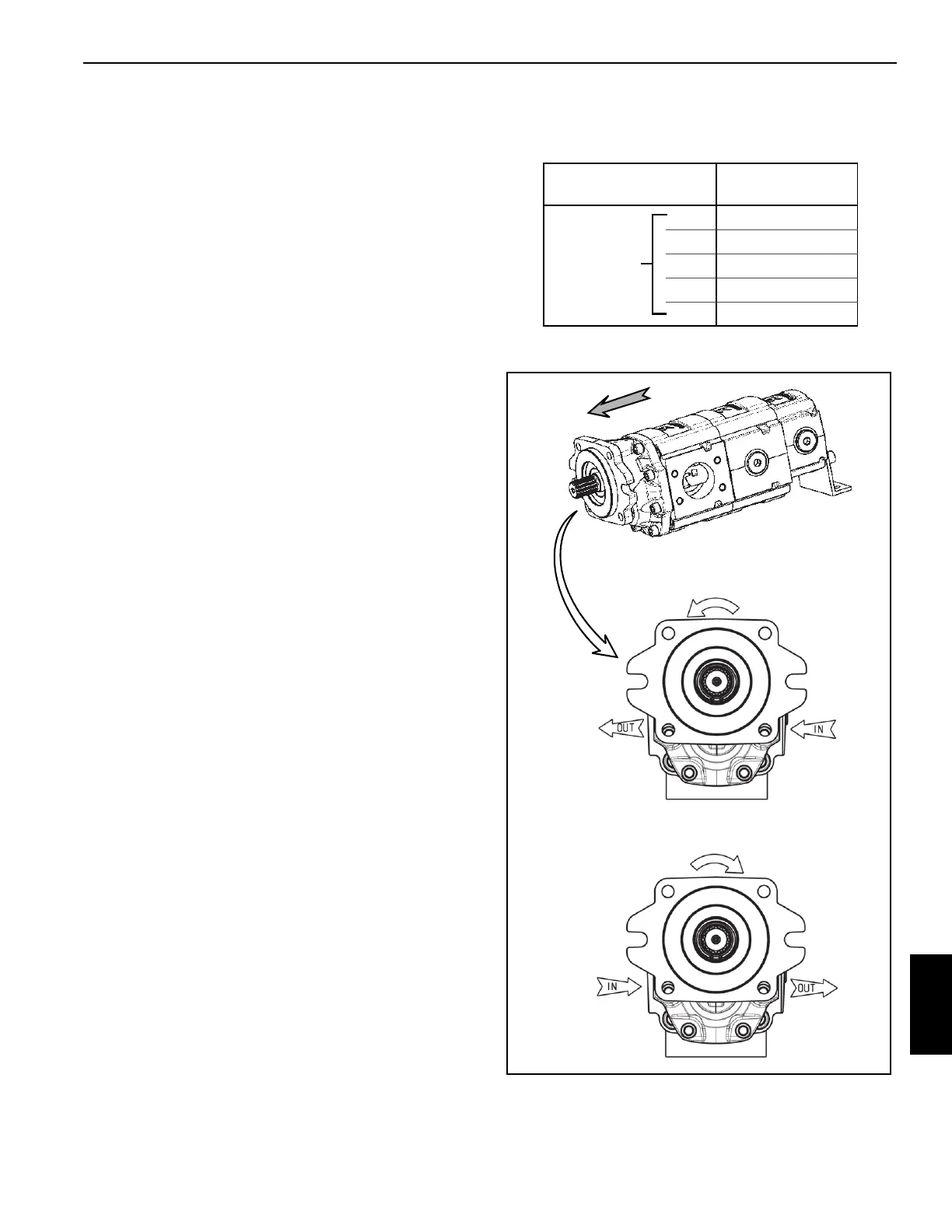

FIGURE 9-3

Counter Clockwise (CCW)

FRONT

Clockwise (CCW)

Loading...

Loading...