National Crane 01-22-2019 Control # 051-08 1-21

1300A INTRODUCTION

Yearly Inspection

Inspect the total length of wire rope annually or more often if

necessitated by adverse conditions. Only inspect the outer

surface of the wire rope. Do not attempt to open the strands

of the rope. Items to include in the yearly inspection are

items listed in the daily inspection plus the following:

• reduction of rope diameter below nominal diameter.

• severely corroded or broken wires at end connections.

• severely corroded, cracked, bent, worn, or improperly

applied end connections.

• areas subjected to rapid deterioration such as:

- sections in contact with saddles, equalizer sheaves,

or other sheaves where wire rope travel is limited.

- sections at or near terminal ends where corroded or

broken wires may protrude.

- sections in contact with stationary surfaces where

abrasion or chafing may take place as a result of

equipment vibration.

• boom nose sheaves, hook block sheaves, boom jib

sheaves, auxiliary boom nose sheaves, and hoist drums

for wear. Damaged sheaves or hoist drums can

accelerate wear and cause rapid deterioration of the

wire rope.

Boom Extension and Retraction Cables

Periodic Inspection

It is recommended that a weekly inspection of all boom

extension and retraction cables be performed using the

following guidelines. The inspection shall cover all visible

areas of the extension and retraction cables of an assembled

boom. Note that extending and/or retracting the boom may

be required to access visual inspection holes.

The inspection shall cover the entire length of the extension

and retraction cables of a disassembled boom prior to

reassembly.This inspection should be used to monitor

progressive degradation and to discover severe damages

necessitating wire rope replacement or equipment repair.

Inspection criteria are as follows:

• reduction of rope diameter below nominal diameter.

• severely corroded or broken wires at end connections.

• severely corroded, cracked, bent, worn, or improperly

applied end connections.

• deterioration in areas such as:

- sections in contact with saddles, equalizer sheaves,

or other sheaves where rope travel is limited.

- sections of wire rope at or near terminal ends where

corroded or broken wires may protrude.

- sections of wire rope in contact with stationary

surfaces where abrasion or chafing may take place

as a result of equipment vibration.

• damaged or wobbly boom extension and retraction

sheaves which can cause rapid deterioration of wire

rope.

• unusual cable sag/stretch. Be sure cables used in sets

all have an equal tension applied. Repeated need for

adjustment of an individual cable is evidence of cable

stretch and indicates the need for a more thorough

inspection to determine and correct the cause.

Wire Rope Replacement (All Wire Rope)

No precise rules can be applied to wire rope replacement

because of the variables involved. Determining the condition

of the wire rope depends largely upon the judgement of a

qualified person.

The information below is excerpted from a National

Consensus Standard as referenced by Federal Government

Agencies and Manitowoc CraneCARE recommendations to

help determine when wire rope needs to be replaced. Wire

rope shall be taken out of service when any of the following

conditions exist:

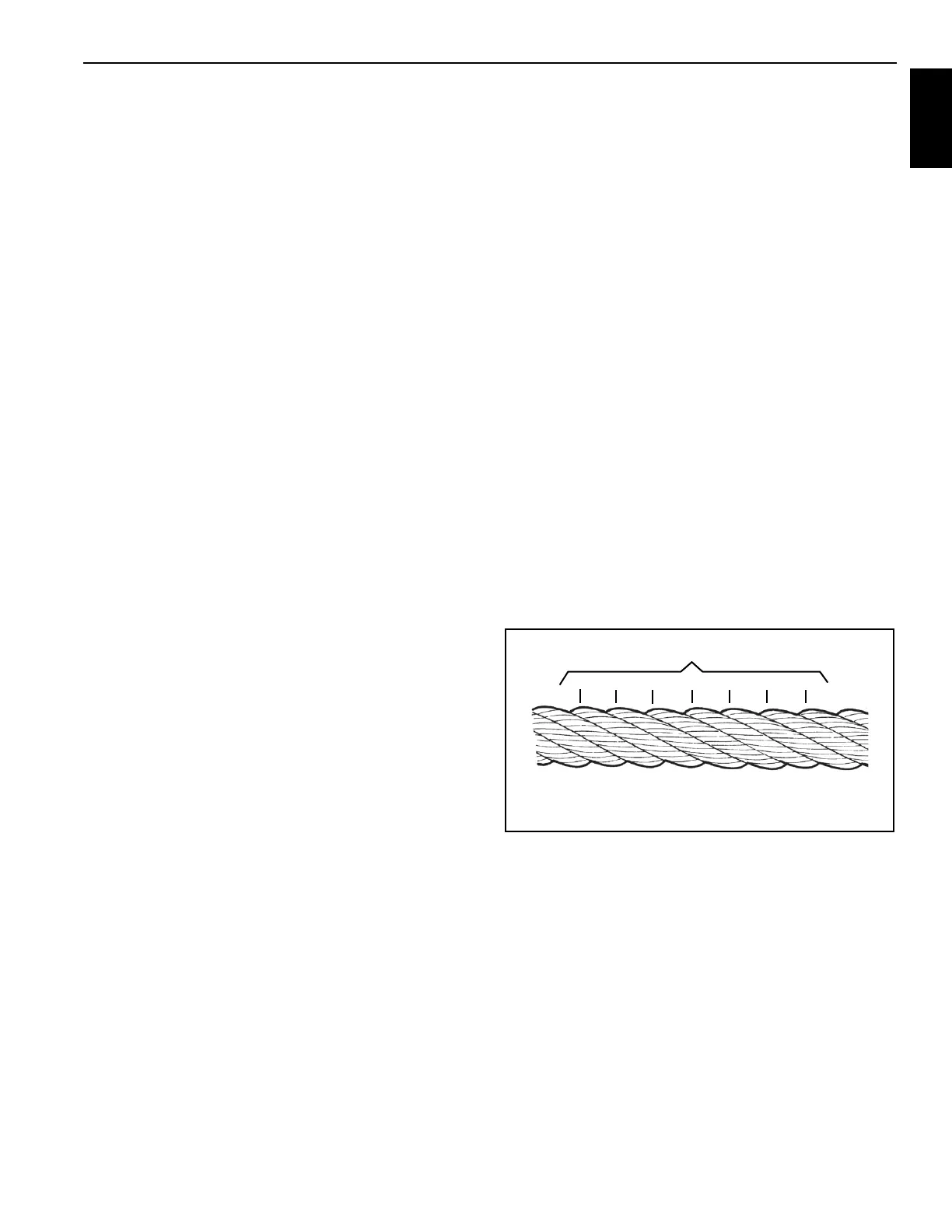

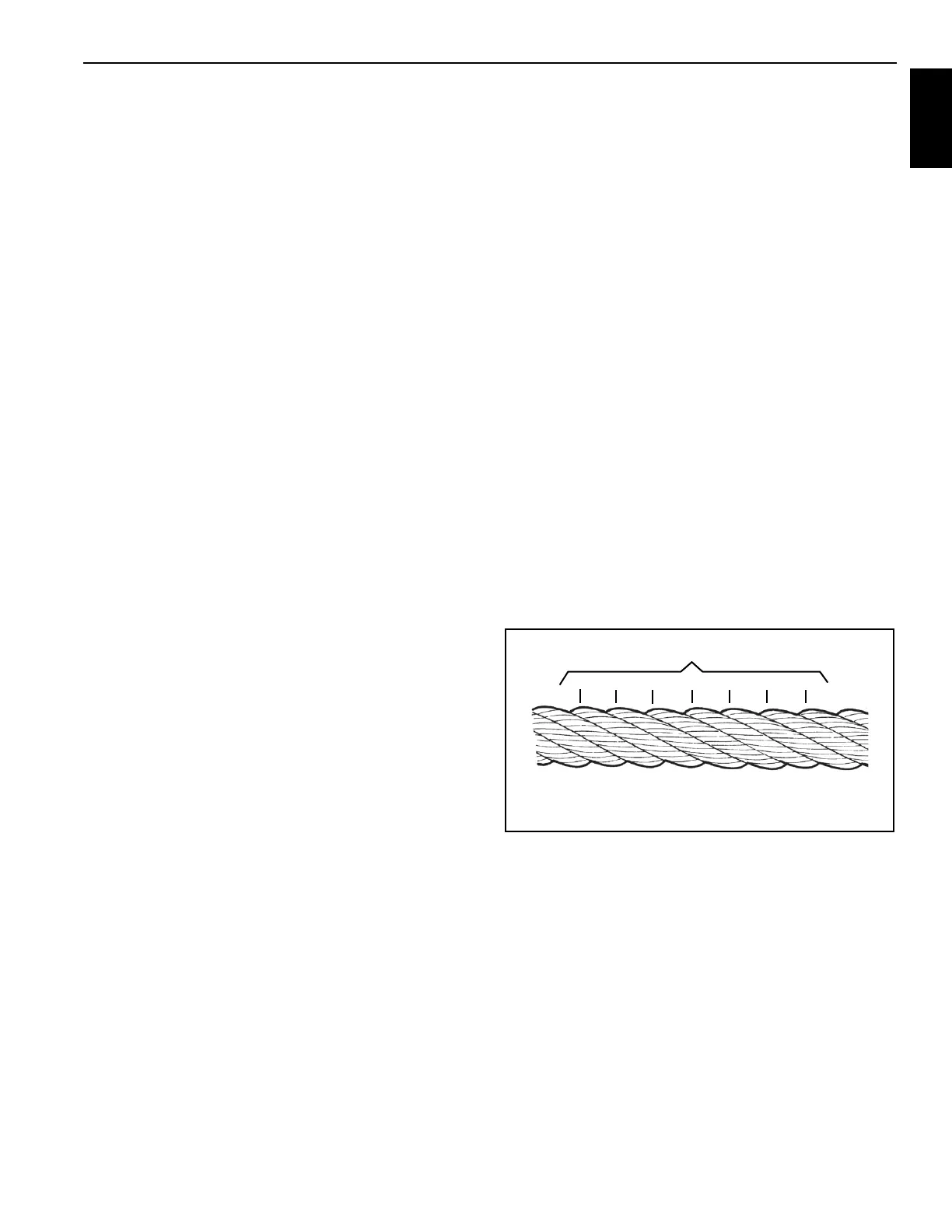

• In running ropes, six randomly distributed broken wires

in one lay or three broken wires in one strand in one lay

(Figure 1-6).

• Kinking, crushing, bird caging, or any other damage

resulting in distortion of the rope structure.

• Evidence of heat damage.

• Reductions from nominal diameter of more than 5%.

• In standing ropes, more than two broken wires in one lay

in sections beyond end connections or more than one

broken wire at an end connection.

• In rotation resistant rope, two randomly distributed

broken wires in six rope diameters or four randomly

distributed broken wires in 30 rope diameters.

• Severe corrosion as evidenced by pitting.

6

1

2

3

4

5

6

One Lay

FIGURE 1-6

One lay is parallel to the rope center-line and is the

distance for one strand to make a complete spiral

around the rope.

Loading...

Loading...