National Crane 01-22-2019 Control # 051-08 1-19

1300A INTRODUCTION

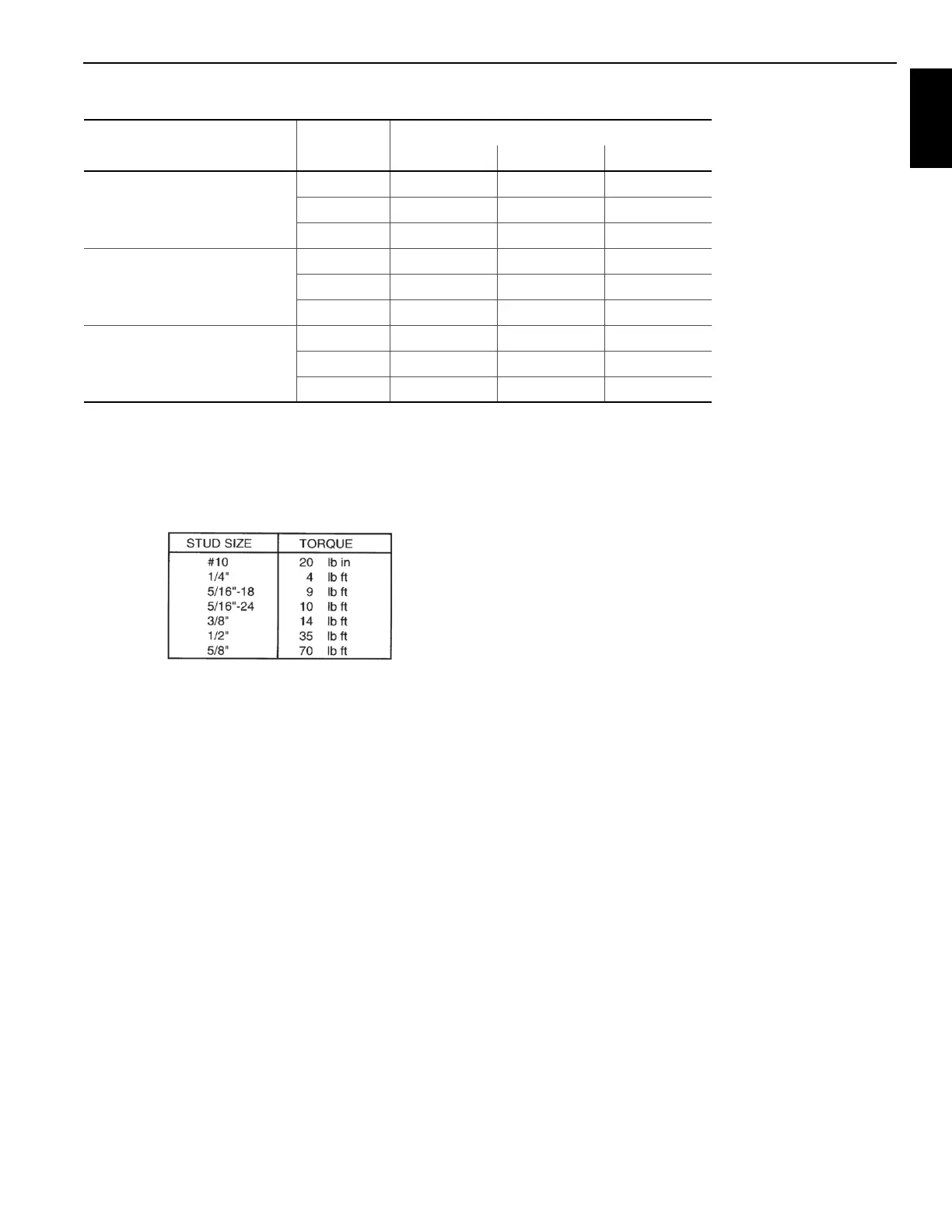

Weld Studs

Unless otherwise specified the following grade 2 torque

values (+/- 10%) apply.

Table 1-13: Weld Stud Torque Values

WIRE ROPE

General

The following information includes inspection, replacement,

and maintenance guidelines for wire rope as established by

ANSI/ASME B30.5, federal regulations, and National Crane

specifications. The inspection interval shall be determined by

a qualified person and shall be based on expected rope life

as determined by experience, severity of environment,

percentage of capacity lifts, frequency of operation, and

exposure to shock loads. Periodic inspections need not be at

equal calendar intervals and should be performed at shorter

time intervals as the wire rope approaches the end of its

useful life. A periodic inspection shall be performed at least

once a year. The following information contains inspection

and maintenance procedures for wire ropes used on

National Crane products as load lines, hoisting cables, boom

extension and retraction cables, pendant cables, and hook

block tie down cables.

Environmental Conditions

The life expectancy of wire rope may vary due to the degree

of environmental hostility. Variation in temperature,

continuous excessive moisture levels, exposure to corrosive

chemicals or vapors, or subjecting the wire rope to abrasive

material can shorten wire rope life. Frequent inspections and

maintenance of the wire rope is recommended for preventing

premature wear and to insure long-term performance.

Dynamic Shock Loads

Subjecting wire rope to abnormal loads shortens the ropes

life expectancy. Examples of this type of loading are as

follows:

• High velocity movement followed by abrupt stops

(hoisting or swinging of a load).

• Suspending loads while traveling over irregular surfaces

such as railroad tracks, potholes, and rough terrain.

• Moving a load that is beyond the cranes rated capacity.

Lubrication

The object of rope lubrication is to reduce internal friction and

to prevent corrosion. New lubricant needs be added

throughout the life of the rope. It is important that lubricant

applied needs to be compatible with the original lubricant.

Consult the rope manufacturer for proper lubricant. The

lubricant applied shall be of the type which does not hinder

visual inspection. Those sections of rope which are located

over sheaves or otherwise hidden during inspection require

special attention when lubricating rope.

During fabrication, ropes receive lubrication which provides

the rope with protection for a reasonable time if stored under

proper conditions. After the rope is put into service, periodic

applications of a suitable rope lubricant are required. The

wire rope lubricant should have the following characteristics:

• Be free from acids and alkalis and should have sufficient

adhesive strength to remain on the ropes.

M30x2

8.8 1661 1597.5 1534

10.9 2336 2246.5 2157

12.9 2800 2695 2590

M33x2

8.8 2141 2059 1977

10.9 3155 3034 2913

12.9 3692 3550.5 3409

M36x2

8.8 2795 2688 2581

10.9 4118 3960 3802

12.9 4818 4634 4450

Table 1-12 Metric Series with Fine Threads – Untreated (black finish) (Continued)

Size

Property

Class

Torque (Nm)

Maximum Nominal Minimum

Loading...

Loading...