HYDRAULIC SYSTEM 1300A

2-20 01-22-2019 Control # 051-08

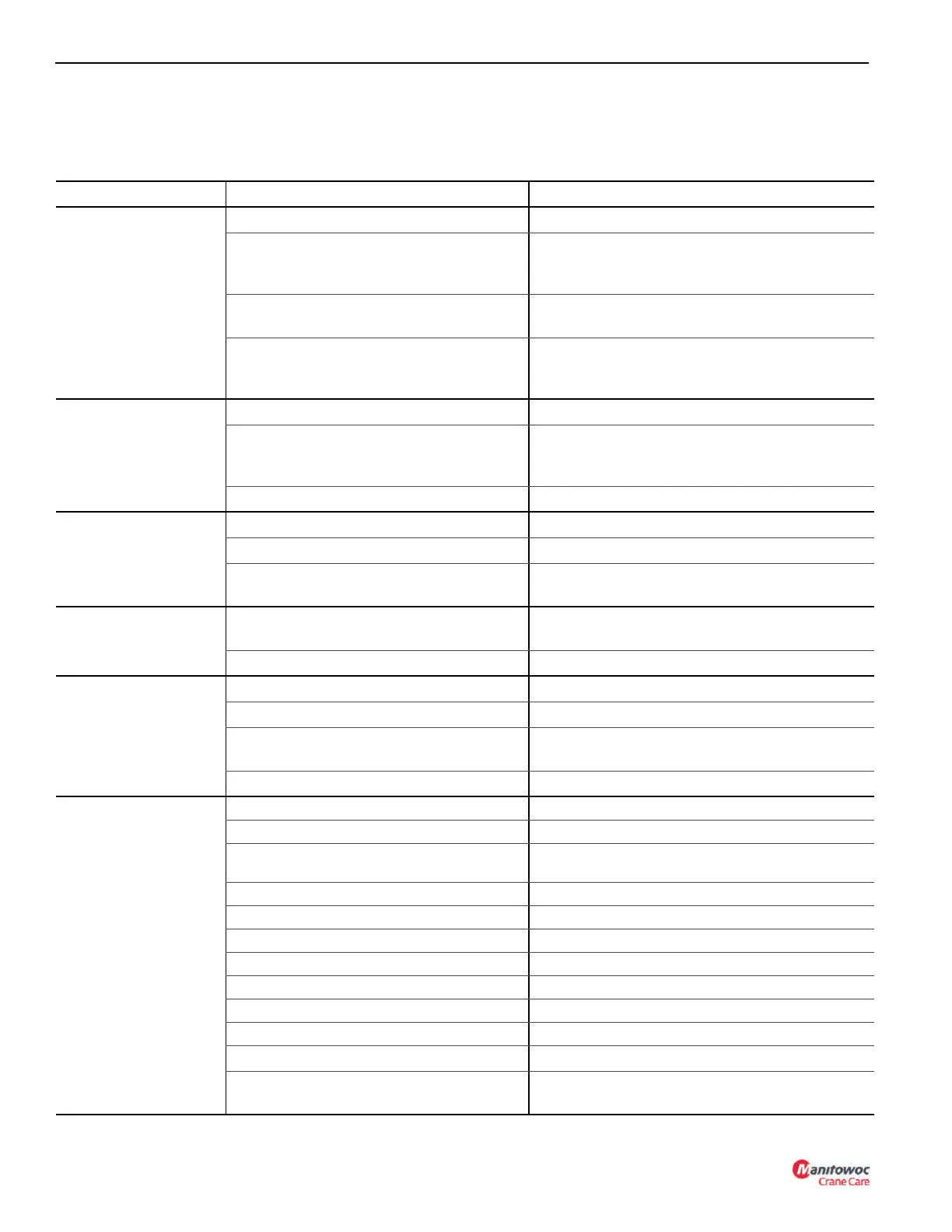

TROUBLE DIAGNOSIS

The following chart lists malfunctions which may occur

during equipment operation, the possible cause, and the

possible solution. These are not all inclusive but are

designed to help isolate the problem and should be checked

before calling

Manitowoc Crane Care.

CONDITION POSSIBLE CAUSE POSSIBLE SOLUTION

No hydraulic oil flows in

systems.

Low hydraulic oil level Fill reservoir.

Reservoir-to-pump suction lines broken or

restricted. Air entering at suction lines. Pump

not priming.

Check that all connections are tight and there are no

cracks. Clean, tighten, repair, or replace parts as

necessary.

Pump shaft sheared or disengaged.

If drive shaft is damaged or sheared, remove and

repair or replace as necessary

Internal contamination.

Drain, flush with recommended oil mixture, then

drain and refill system with recommended hydraulic

oil.

Slow response.

Low hydraulic oil level. Fill reservoir.

Hydraulic oil temperature too high (thin oil) or

too low (thick oil).

If the temperature is too high, check the cooler

circuit. If the temperature is too low, warm up

system.

Faulty pump section(s). Repair or replace pump section(s) or entire pump.

Pump noise

accompanied by

hydraulic oil foaming in

reservoir.

Low hydraulic oil level Fill reservoir.

Excessive engine speed. Regulate engine speed.

Air entering at suction lines.

Check that all line connections are tight. Tighten,

repair, or replace as needed.

Excessive pressure

buildup.

Circuit relief valve malfunction or set too high.

Pressure check circuit relief and adjust or replace

relief valve.

Restricted pump-to-control valve supply line. Clean, repair, or replace line as necessary.

Specific hydraulic system

(lift, hoist, telescope,

swing) not working.

Leak in system. Repair leak.

Faulty directional control valve. Replace valve.

Troubleshoot circuit with schematic.

Poorly adjusted control in circuit. Adjust hydraulic

component.

Faulty hydraulic cylinder, motor, or valve. Replace faulty component.

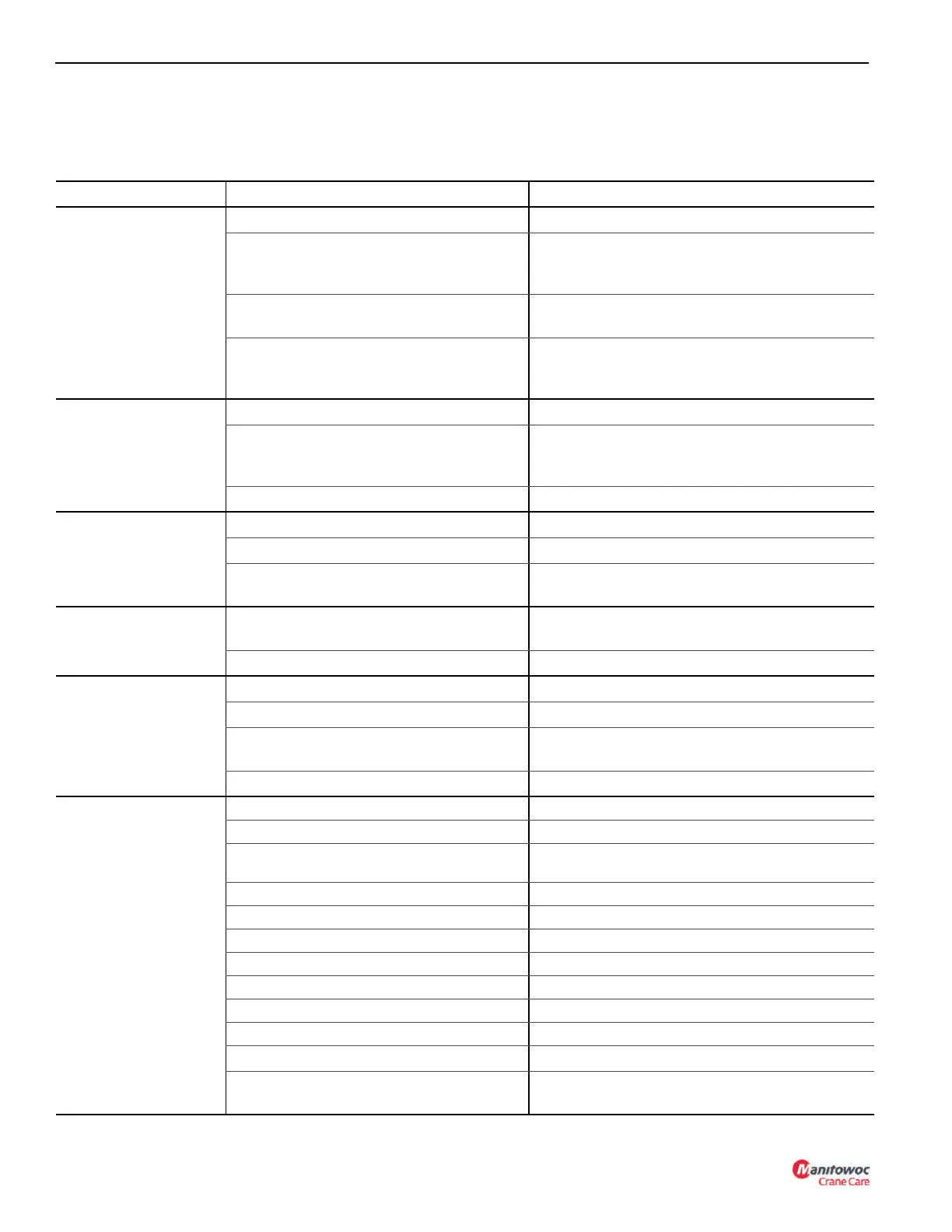

No response to control

Crane function power switch off Turn crane function power switch on.

Load too heavy. Check Capacity Chart.

RCL inoperative. Insure RCL is programmed properly and Anti-Two Block/

Overload solenoids are powered.

PTO not engaged. Engage PTO.

Low hydraulic fluid supply. Check and fill as required.

Suction line blocked. Drain tank and hose and remove blockage.

Broken hydraulic pressure line. Replace as required.

Defective hydraulic pump. See Pump Service Manual.

Incorrect relief valve setting. Adjust relief.

Relief valve sticking. Clean relief or replace.

Hydraulic controllers inoperative Check for pilot pressure at main valve bonnets.

Mesh screen in crane manifold clogged (pilot

circuit)

Remove and clean or replace screen.

Loading...

Loading...