HYDRAULIC SYSTEM 1300A

2-6 01-22-2019 Control # 051-08

• To remove entrapped air from telescope cylinders, lower

the boom to below horizontal and fully telescope the

boom in and out several times.

• If the air is not readily removed, lower the boom to below

horizontal, extend the telescope cylinders as far as

practicable, and allow the boom to remain in this position

overnight. This should allow entrapped air to find its way

to the holding valve so that telescoping the boom IN the

next morning should force the air back to the reservoir.

Ensure the boom is first telescoped IN (not OUT) in the

morning. Telescoping OUT may cause air to be forced

back into the cylinder.

• Entrapped air may be removed from cylinders having

wet rods by cycling. On certain cylinders, a plugged port

is provided on the rod end to bleed off entrapped air.

• In the event that air entrapment should persist, bleeding

of air by loosening various clamp and screw type fittings

may become necessary.

• If the above procedures fail to eliminate air entrapment,

contact your authorized National Crane distributor.

Parts Replacement

Parts found damaged or out of tolerance when maintenance

is being performed should be replaced. Refer to the Grove

Parts Catalog for proper replacement parts.

Maintenance Records

Dated records must be kept for inspection of critical

components such as, brakes, crane hooks, wire ropes,

hydraulic cylinders and relief valve pressure settings. These

records must be kept where they can be easily obtained and

reviewed.

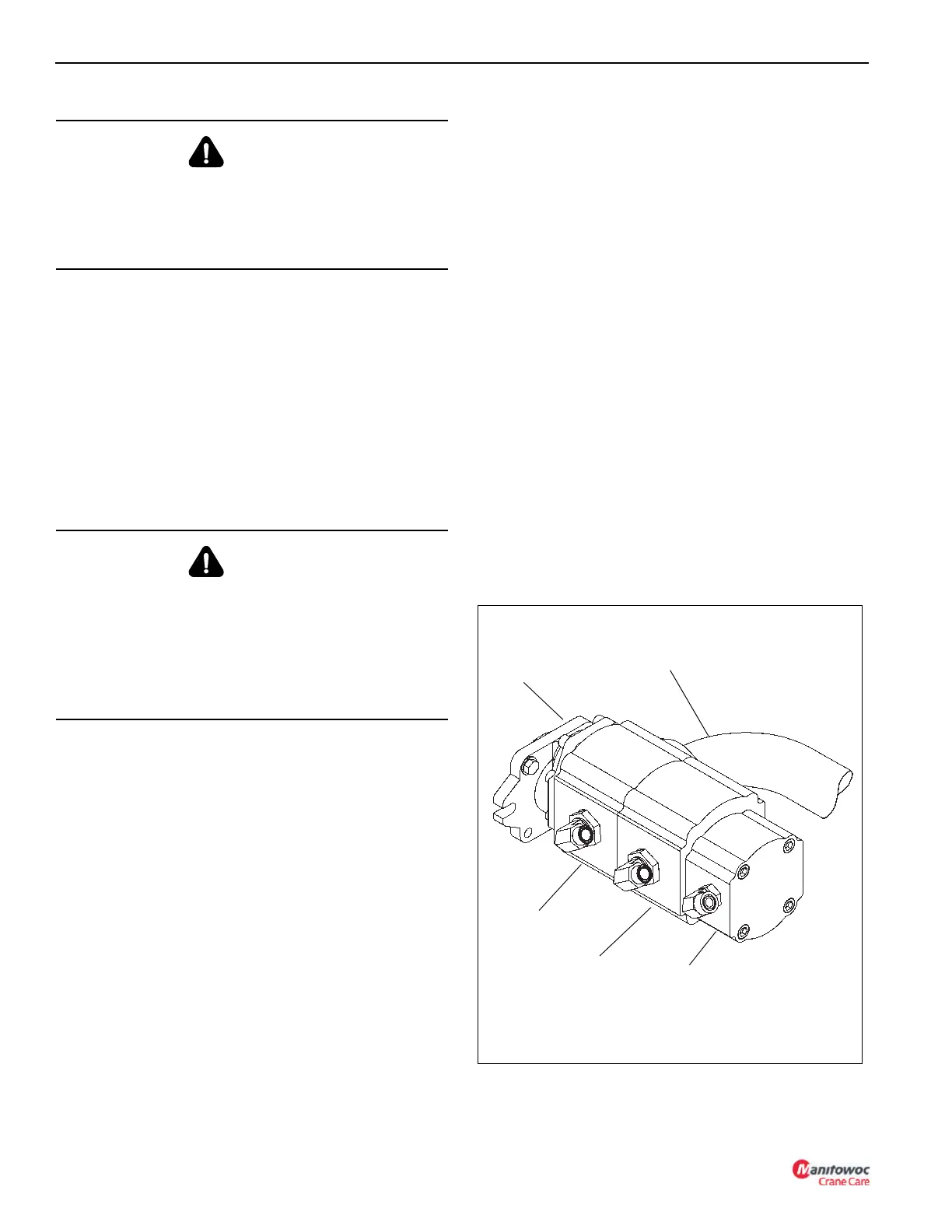

HYDRAULIC PUMP

The hydraulic system pressure is supplied by a three section

hydraulic gear pump mounted on the truck power take off

(PTO). Hydraulic system operating temperature is from

-20°F to +200° F (-28.8°C to 93.3° C). The pump is driven

counter clockwise and supplies the following at 1800 rpm:

• P1 supplies 34 gpm (128.7 lpm) at 3300 psi (227.5 bar)

for the hoist circuit.

• P2 supplies 29 gpm (109.7 lpm) at 3600 psi (248.2 bar)

for the telescope and lift circuits.

• P3 supplies (52.9 lpm) 3000 psi (206.8 bar) at 14 gpm

for the outrigger circuit and 12 gpm for the swing circuit.

A directional control valve mounted in the enclosure on the

turret controls direction of the swing, hoist, lift, and telescope

circuits.

A flow divider located in the crane manifold mounted in the

enclosure on the turret provides pilot pressure for the

controllers, swing brake release pressure, and burst of

speed flow.

CAUTION

Always locate the machine on a firm supporting surface,

extend the outriggers and level the machine and position

the boom over the front to extend the boom at low angles.

Injury or damage to the machine may result if this caution

is not followed.

CAUTION

Do not attempt to loosen fittings in pressurized lines or

while the hydraulic pumps are in operation.

Extreme care must be used when removing any plugs or

restrictions from a hydraulic system suspected to have

entrapped air that may be pressurized. Moderate to minor

injury may result from pressurized air in a hydraulic

system.

Section P1

Section P2

Section P3

Suction Supply

3 Section

Gear Pump

FIGURE 2-1

Loading...

Loading...