National Crane 01-22-2019 Control # 051-08 1-7

1300A INTRODUCTION

Fatigue Of Welded Structures

Highly stressed welded structures are subject to cracking

(fatigue) when repeatedly subjected to varying stresses

caused by twisting, shock, bending, and overloads. Inspect

equipment periodically for weld fatigue. The frequency of

inspections depends on the age of the equipment, the

severity of the application, and the experience of the

operators and the maintenance personnel. The following are

known high stress areas and should be inspected as part of

a preventive maintenance program:

• Hydraulic cylinder and boom pivot attaching points.

• Outrigger pads, beams, boxes and attachment

structures.

• On the frame in the area of doubler plates and

crossmembers.

• Turntable bearing connection (where bearing is welded

to the crane turret).

• Counterweight support structures (were applicable).

• Hydraulic cylinder end connections.

The above is provided only as a guide and your inspection

plan should not be limited to the areas listed. A visual

inspection of all weldments is good practice.

Loctite

Follow the directions on the Loctite container. There are

different Loctite types for different applications. The following

types of Loctite brand adhesives are available from the parts

department of the local National distributor.

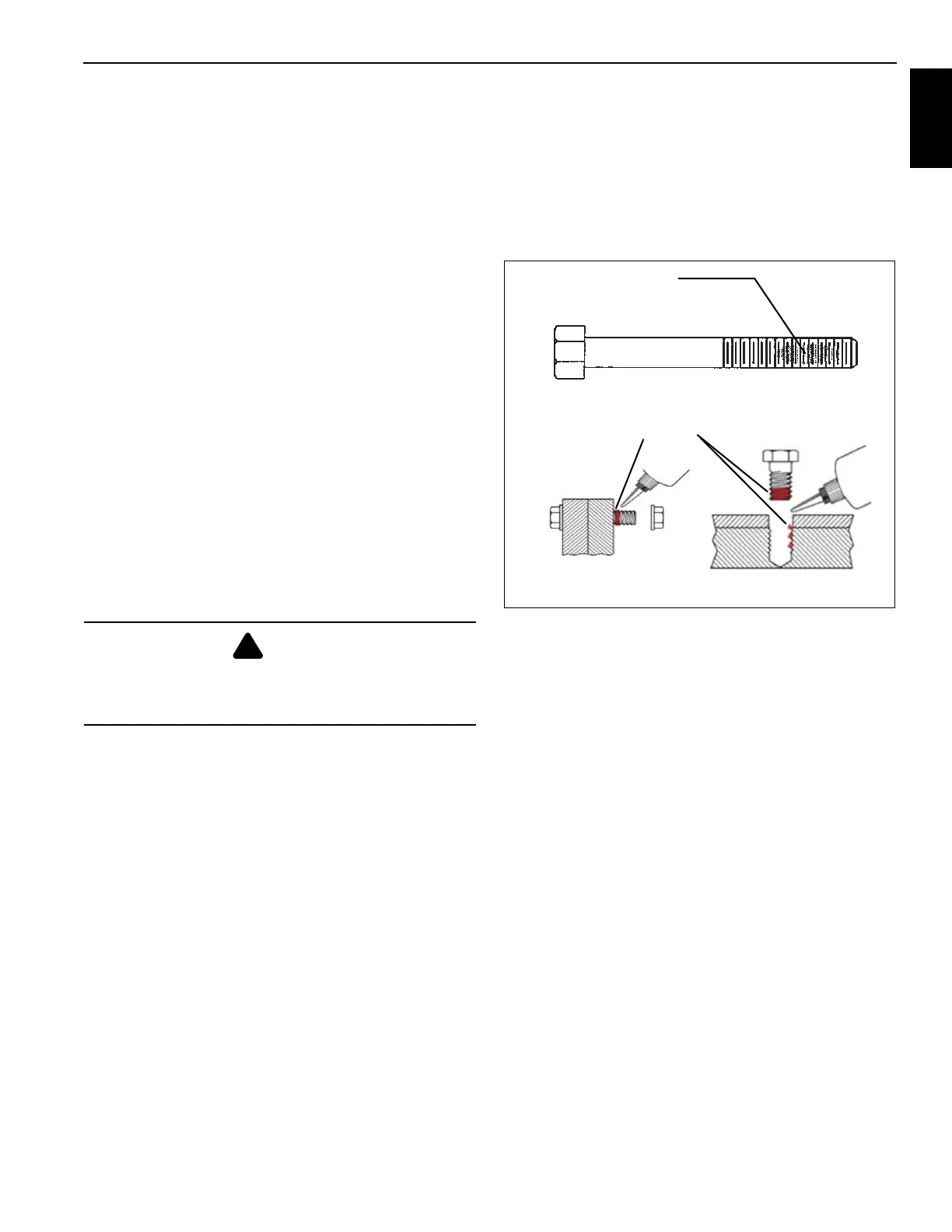

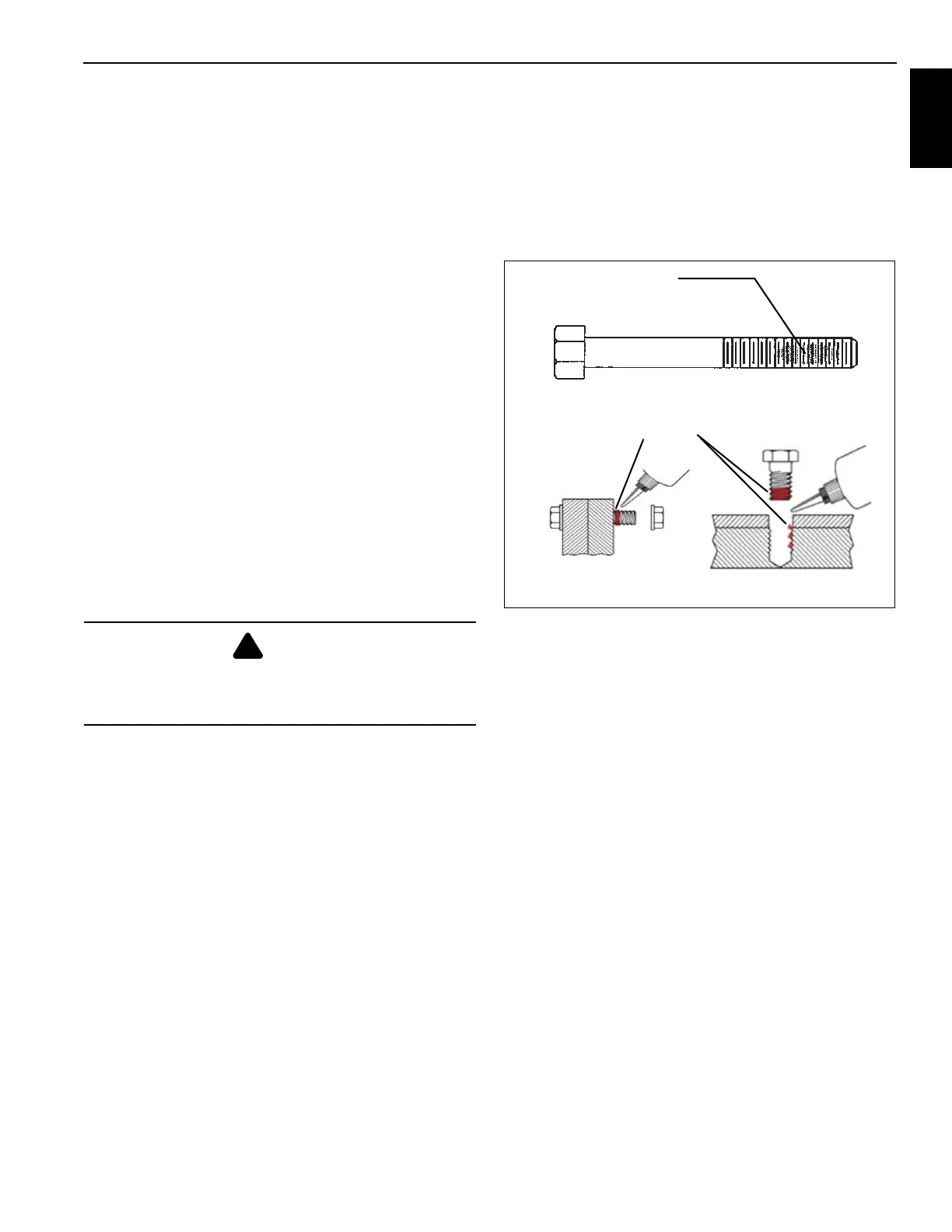

Application of Medium Strength Loctite®

NOTE: The fastener may be re-used; the adhesive may be

re-applied over cured adhesive residue.

The following procedure covers the proper application and

curing method for medium strength Loctite® adhesive/

sealant (Loctite® #243).

NOTE: Ensure the threaded surface, both male and

female, is clean of contaminants and free of dirt

and oil.

Adhesive/Sealant Application

1. Apply a bead perpendicular to the thread, several

threads wide, in the approximate area of threaded

engagement (see Figure 1-1).

2. In a blind hole application, a bead of several drops of

adhesive should be applied into the bottom of the hole to

be hydraulically forced up during engagement.

3. After application and engagement of mated threads,

fixturing will occur within five (5) minutes. Time required

to achieve full strength is 24 hours.

Torque Values

The following tables list the torque values for both ASME

standard and metric fasteners. The tables list the values for

grade 5 and grade 8 zinc-flake coated, untreated (black)

finish and stainless steel fasteners.

DANGER

Loctite type adhesives contain chemicals that may be

harmful if misused. Read and follow the instructions on

the container.

4203

FIGURE 1-3

Bead Application

Bead Application

8213-1

8213-2

Loading...

Loading...