National Crane 01-22-2019 Control # 051-08 2-15

1300A HYDRAULIC SYSTEM

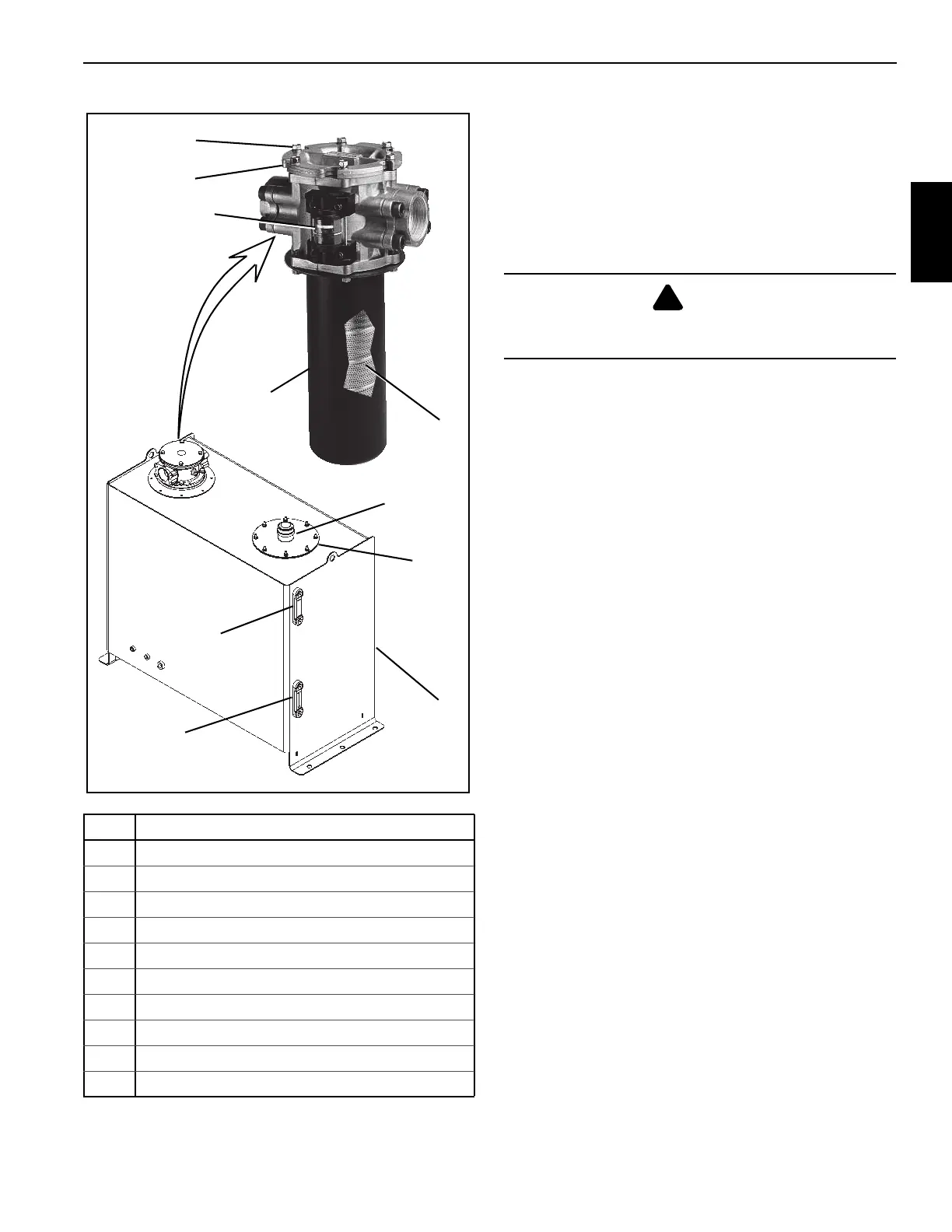

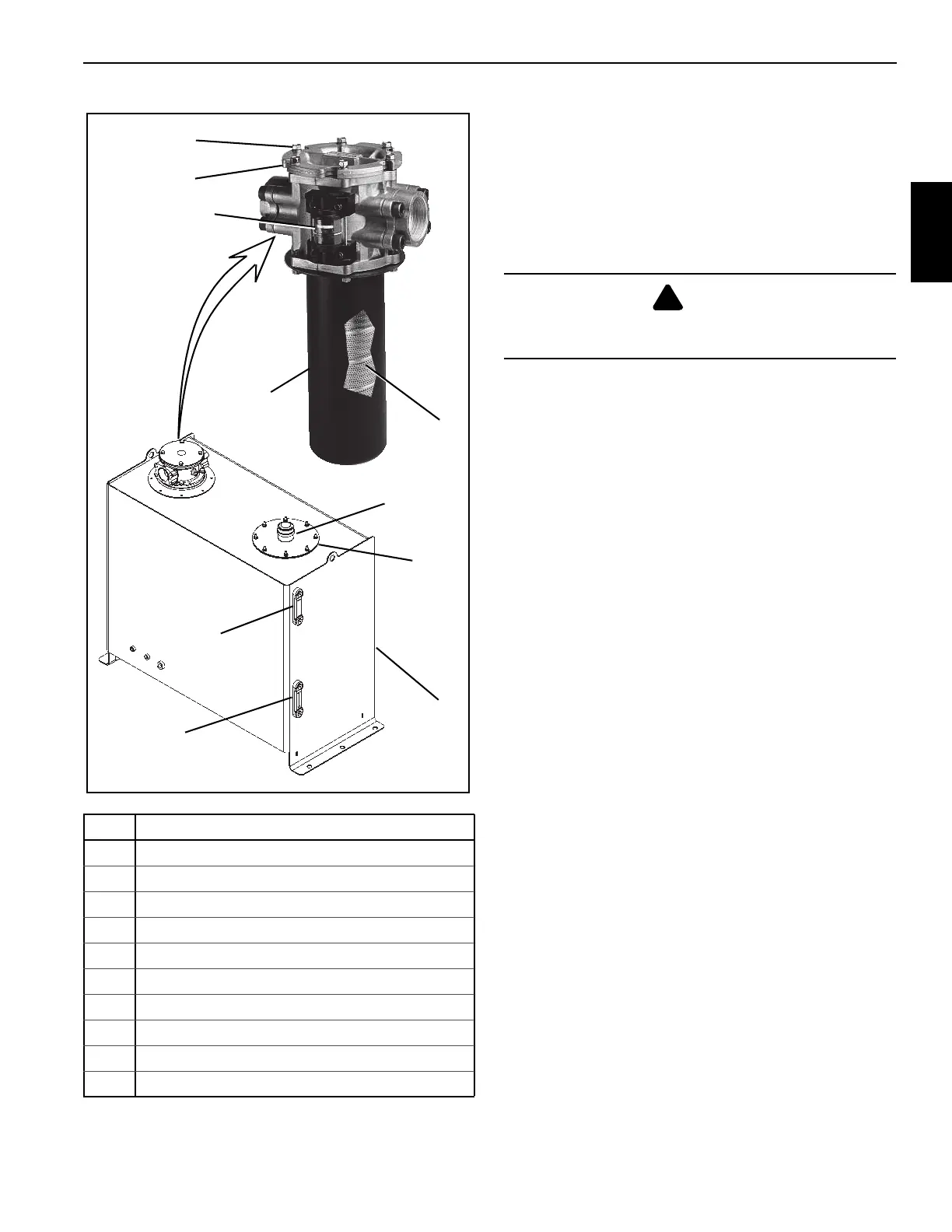

Hydraulic Filter Replacement

The filter is mounted in the oil reservoir, and is a replaceable

element type.

The filter must be serviced with National Crane replacement

elements at recommended intervals to assure the warranty

remains in effect.

Element Removal

1. Shut down the hydraulic system.

2. Wipe any dirt from the filter head and cap assembly.

3. Loosen the six bolts securing the filter cap to the filter

head.

4. Twist to unlock and remove the filter cap.

5. Remove the filter element from the filter bowl (housing).

6. Ensure the new filter element is correct by comparing

their part numbers with the part numbers of the used

filter element.

7. Discard the used filter element.

Element Installation

1. Install the new element into the filter bowl (housing).

2. Install the filter cap and twist to lock in place.

3. Tighten the six bolts to secure the filter cap.

4. Activate the hydraulic system and check for leaks. Make

repairs as needed.

Hydraulic Oil Cooler

A hydraulic oil cooler (Figure 2-11) is located on the driver

side of the hydraulic reservoir. The oil cooler return circuit is

in parallel with the reservoir return circuit. A 30 psi (206 kPa)

check valve in the cooler line regulates flow through the oil

cooler. When the hydraulic oil is cold, most of the return oil

goes directly to the tank. As the oil warms up and becomes

thinner, more oil goes through the cooler.

NOTE: A temperature sensor located in swivel port (1)

monitors the temperature of the hydraulic oil and

illuminates a light on the crane cab console when

the temperature reaches 190° F (87.7° C).

The oil cooler fan is controlled by a relay in the fan housing.

To access the relay, remove the assess panel on the side of

the housing. A temperature switch located in the cooling core

energizes the fan relay when the oil temperature reaches

140°F (60 °C). See Figure 9-15 for fan installation.

Item Component

1 Hydraulic Reservoir

2 Temperature Gauge

3 Hydraulic Oil Level Gauge

4 Access Cover

5 Fill Cap

6Bowl

7 Filter Element Gauge

8Filter

9 Filter Cap

10 Capscrews (6)

DANGER

Ensure that hydraulic system is shut down and the

pressure is relieved.

Loading...

Loading...