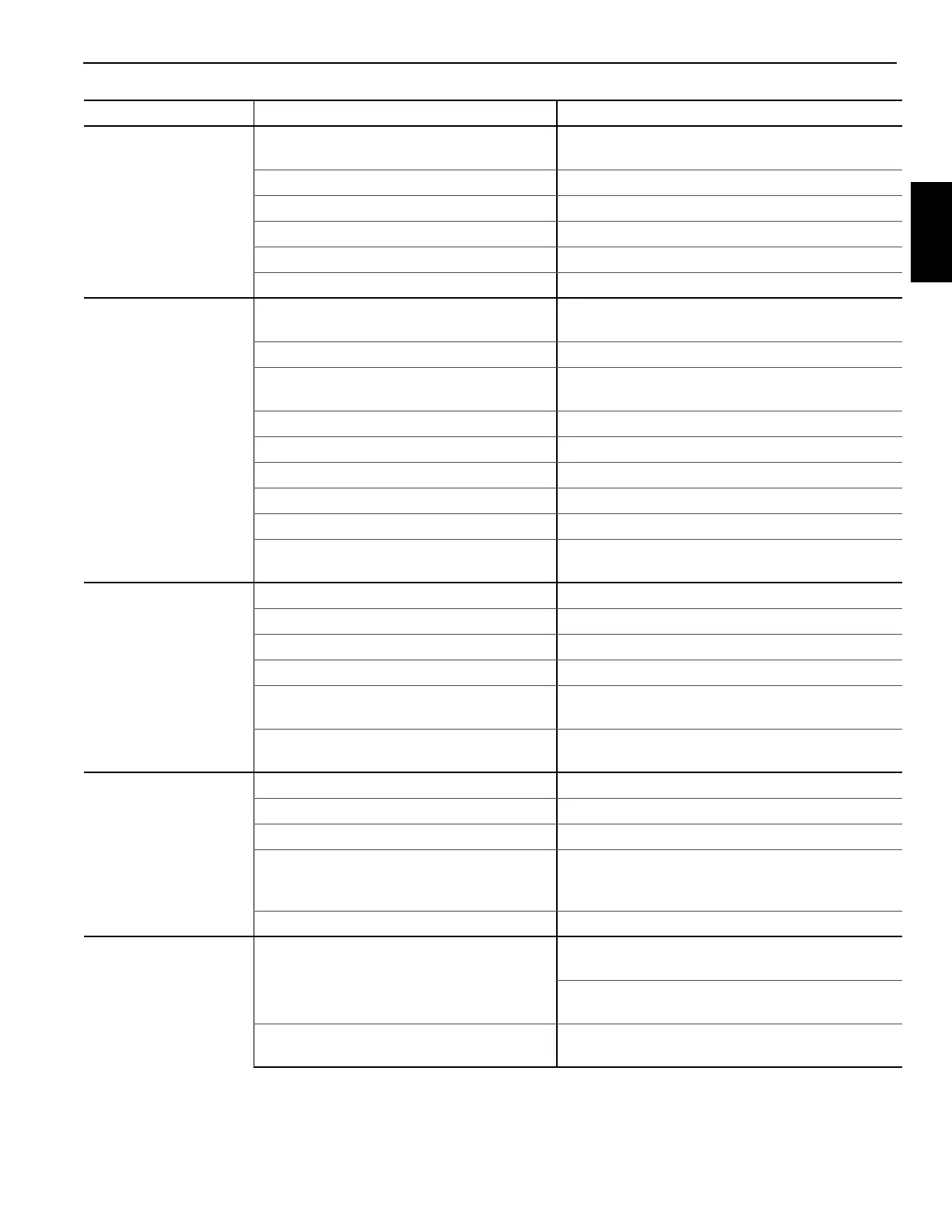

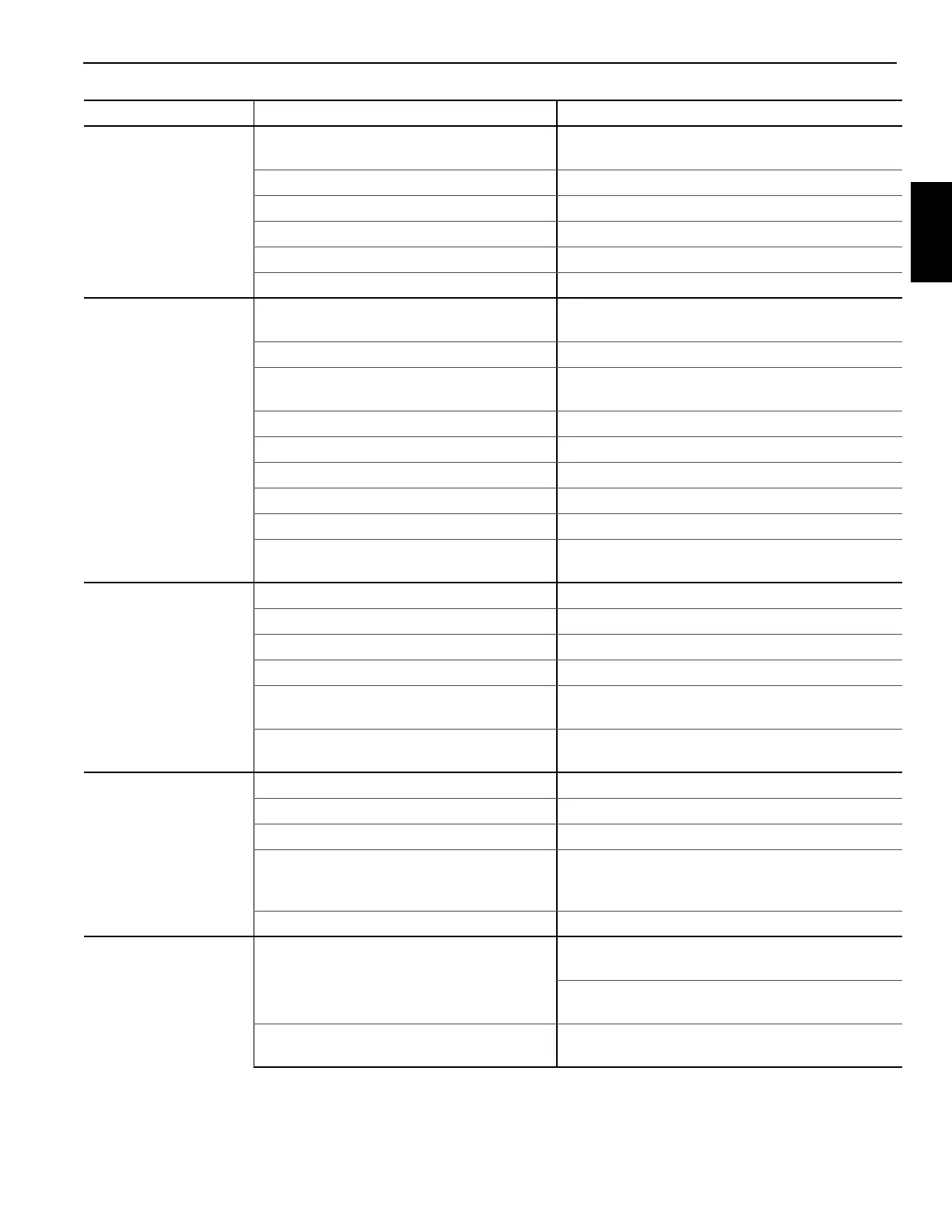

National Crane 01-22-2019 Control # 051-08 2-21

1300A HYDRAULIC SYSTEM

Poor hydraulic system

performance

Pump not operating at proper speed or

displacement.

Check PTO ratio, pump size and engine speed for

proper oil flow.

Low hydraulic fluid supply. Check and fill as required.

Relief valve sticking. Remove and clean.

Relief setting too low. Readjust to proper setting.

Worn pump, motor or cylinder. Replace bad part.

Plugged filter. Change filter.

Poor hydraulic system

performance (continued)

Valve spools not fully open.

Pilot pressure at valve bonnets should be 100 to 350

PSI (0.7 to 2.4 MPa) so valve has full throw.

Plugged diffuser Remove from tank and clean.

Boom holding valves out of adjustment or

dirty.

Adjust or clean as required.

Hydraulic oil too cold. Warm oil or use less viscous oil.

Line restricted. Check lines; clean and repair as necessary.

Plugged suction strainers. Remove strainers from tank and clean.

Internal valve crack. Replace valve.

Load too heavy. Check Capacity Chart and reduce load.

Oil temperature too high.

Reduce engine RPM or slow cycle time to cool oil.

Add oil cooler option if not equipped.

Turn moves erratic or

loosely (Glide Swing

System)

Loose swing bearing. Torque bearing mounting bolts.

Loose swing gearbox mounting bolts. Torque bolts.

Worn gears or bearing. Replace worn parts or adjust gearbox spacing.

Operator control of lever too erratic. Operate controls smoothly.

Park brake not releasing.

Check pressure in brake release line. Must be 300 -

500 PSI (2.1 - 3.4 MPa).

Dynamic brake not properly applying.

Check dynamic brake pressure. Must modulate

between 0 - 500 PSI (0 - 3.4 MPa).

Turn does not function

(Glide Swing System)

Attempting to swing up too much of incline. Level machine.

Turn circuit relief valves sticking. Clean and check circuit pressure.

Swing bearing drag. Lubricate thoroughly as upper is rotated.

Swing brake on.

Select swing brake control switch on and check

swing brake release pressure at 300 - 500 PS (2.0 -

3.4 MPa).

Swing speed adjustment set too low. Adjust valve on turn motor.

Turn moves erratic or

loosely (Standard

system)

Brake not holding properly.

Check for no pressure in brake pilot line when turn is

in neutral.

Replace worn brake parts or shim brake to proper

torque.

Brake releasing at wrong time or erratically.

Bleed air from brake with bleed screw on side of

brake.

CONDITION POSSIBLE CAUSE POSSIBLE SOLUTION

Loading...

Loading...