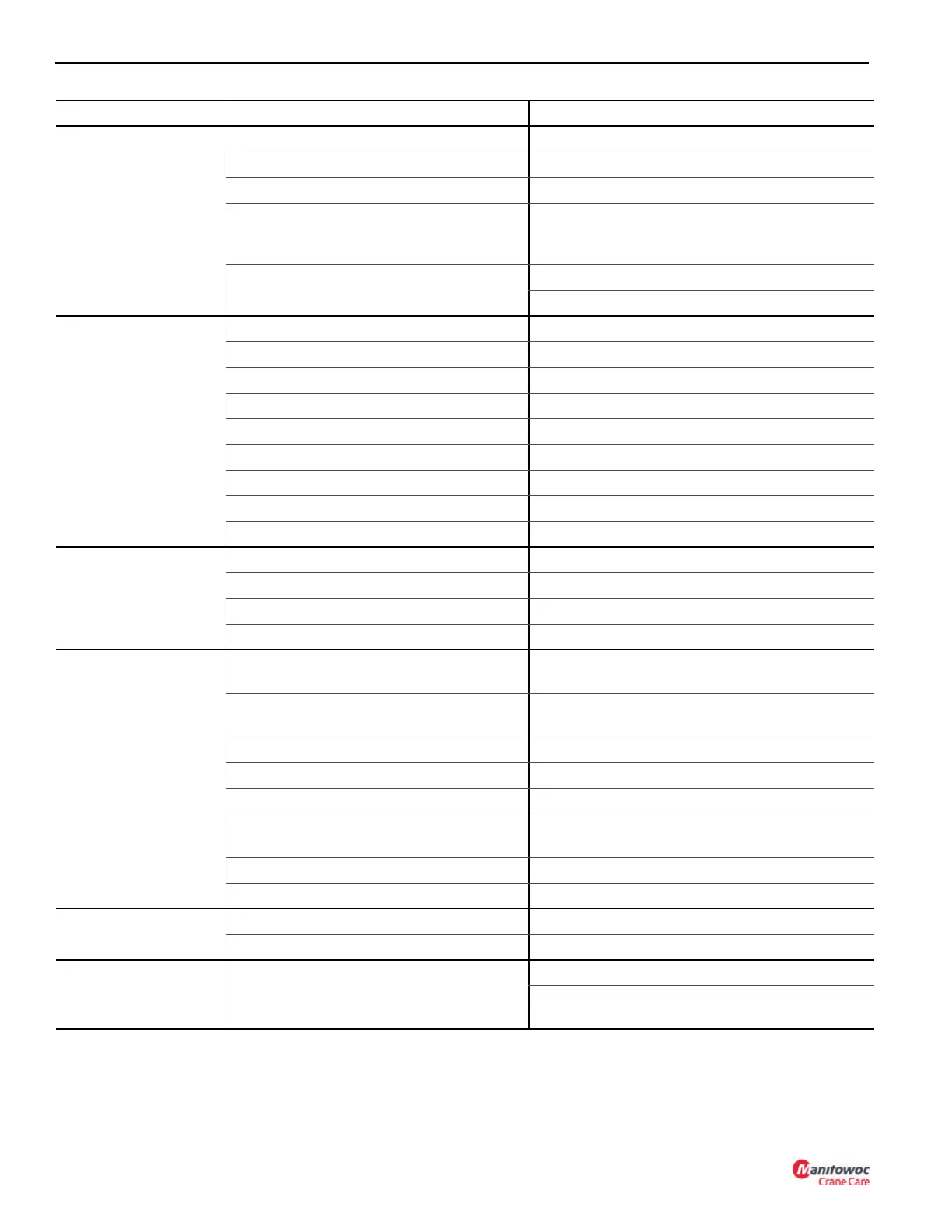

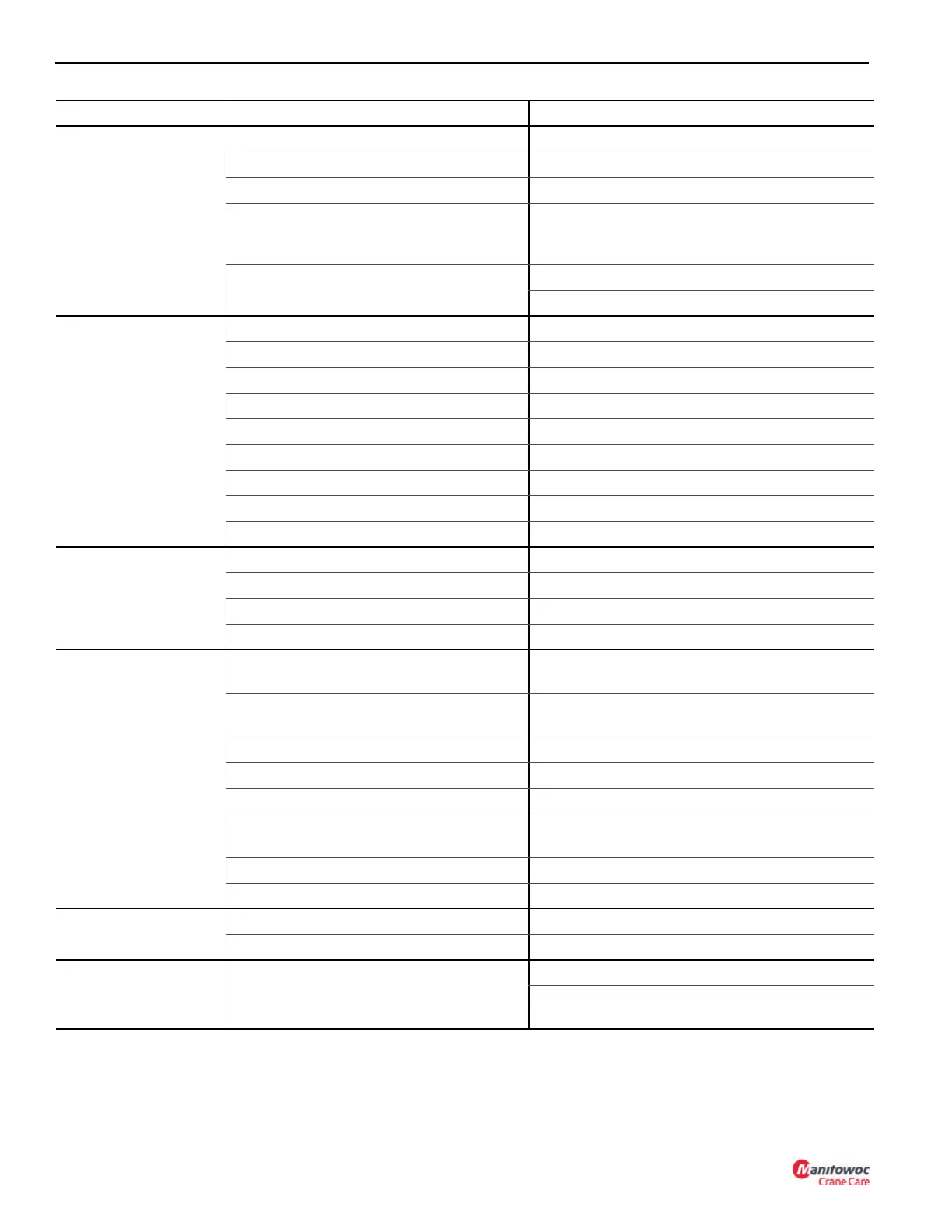

HYDRAULIC SYSTEM 1300A

2-22 01-22-2019 Control # 051-08

Turn does not function

(Standard System)

Attempting to swing up too much of incline. Level machine.

Turn circuit relief valves sticking. Clean and check circuit pressure.

Swing bearing drag. Lubricate thoroughly as rotating boom.

Brake not releasing properly.

Check for 200 + PSI (1.4 MPa) brake pilot pressure.

Clean pilot line or adjust motor counterbalance

valves.

Swing speed adjustment set too low.

Adjust or clean brake for proper release.

Adjust valve on turn motor.

Excessive noise during

operation

Low oil temperature. Allow unit to warm up.

Low hydraulic oil supply. Check and fill with crane in travel position.

Suction line kinked, collapsed or blocked. Clear blockage.

Hydraulic oil too thick. Warm oil or use oil more applicable to environment.

Plugged suction strainers. Remove from tank and clean.

Relief valve chattering. Dirt in relief valve or damaged relief.

Swing brake dragging. Bleed air from brake line at fitting on brake housing.

Hydraulic tubing vibration. Check for loose tubing.

Tank breather plugged. Clean breather.

Cylinders drift

Worn or damaged piston seals. Replace as required.

Air in hydraulic oil. Cycle operate crane cylinder to remove air.

Loose holding valve. Tighten valve.

Dirt in holding or check valve. Clean valve.

Hoist will not lift or hold

load

Load too heavy.

Check load and change to Lo-speed/Hi-pull or

applicable multipart reeving.

Hoist or boom overloaded causing RCL

shutdown.

Reduce load or reeve hoist properly

forshutdown.load lifting.

Relief valve setting too low. Check and adjust if required.

Motor worn. Replace motor.

Sprag clutch defective. Clean or replace Sprag clutch.

Load block too close to boom tip, two-block

system shut down.

Lower load or retract boom. Check two-block

system, repair if defective.

Brake worn out. Repair or replace brake.

Anti-two-block system defective. Repair anti-two-block system.

Hoist gearbox heats

Gearbox grease low. Check and fill as required.

Duty cycle too high. Reduce cycle time or speed of engine.

Truck engine will not start

from crane cab

Truck ignition switch on.

Turn truck ignition off.

Check all other normal motor vehicle systems as

outlined by normal practice.

CONDITION POSSIBLE CAUSE POSSIBLE SOLUTION

Loading...

Loading...