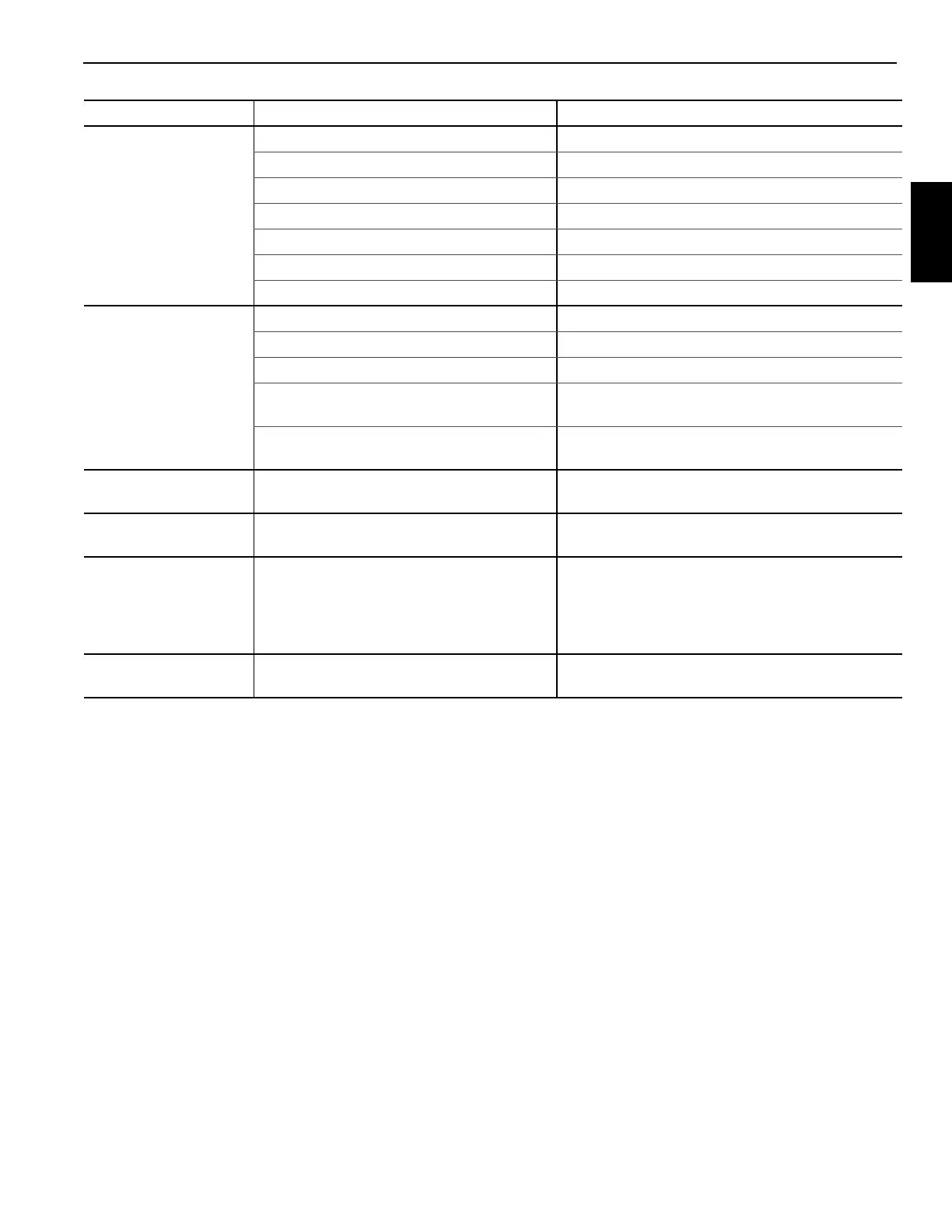

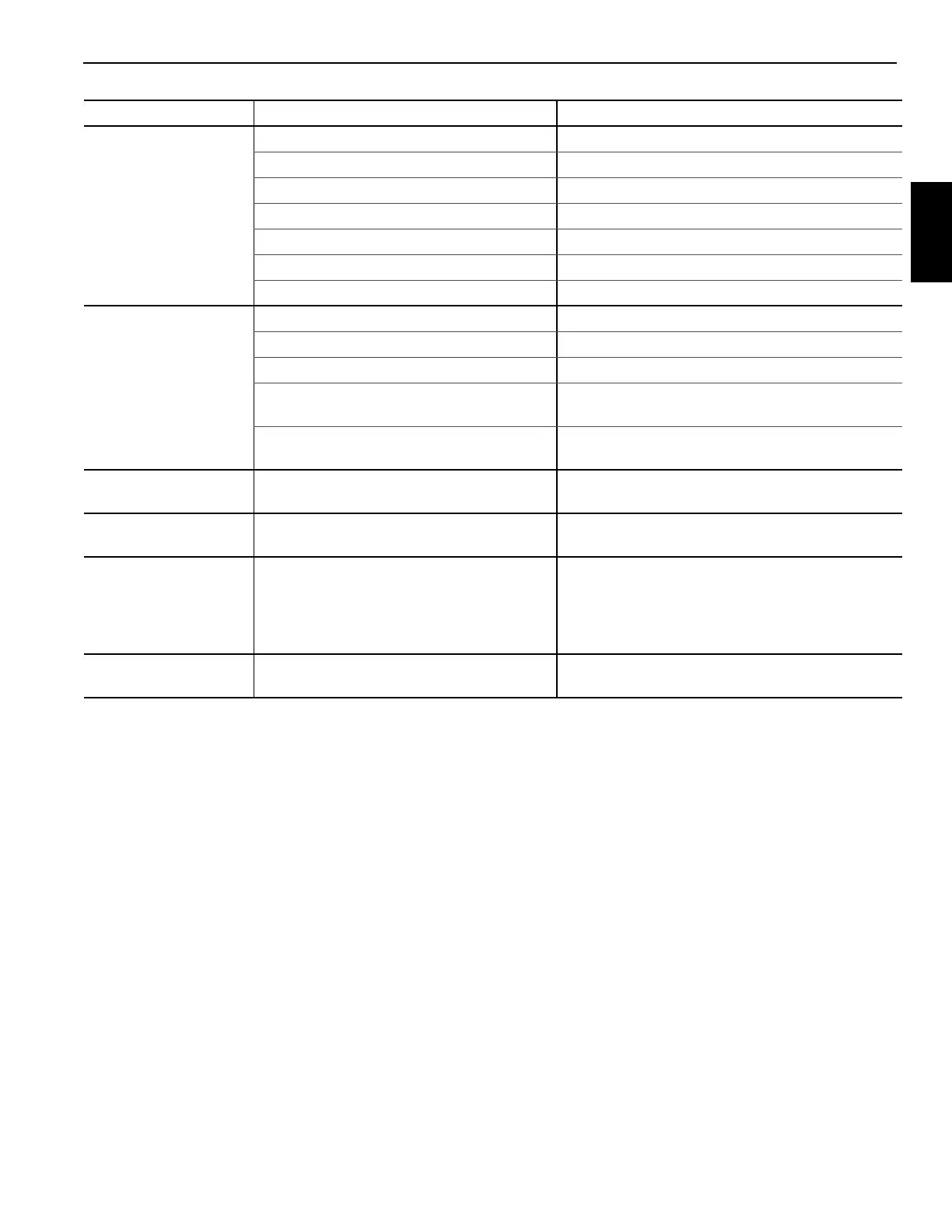

National Crane 01-22-2019 Control # 051-08 2-23

1300A HYDRAULIC SYSTEM

Boom chatters during

extension/retraction or

doesn’t proportion

properly

Boom sections need lubrication. Use dry lubricant or replace lube plugs in wear pads.

Wear pads not shimmed correctly. Reshim as described in boom assembly section.

Boom hot from high extend duty cycle. Slow duty cycle to cool boom and pads.

Worn wear pads. Replace pads.

Cylinder came out of lock. Disassemble and reinstall keepers.

Extension cables out of adjustment. Readjust cables and tension properly.

Extend or retract cables broken. Disassemble and inspect and replace cables.

Boom will not extend

Cables not attached correctly. Reconnect, replace and/or adjust cables.

Anti-two block system shut down. Lower hook, and extend load.

Defective anti-two block system. Check anti-two block system; repair if defective.

Overload causing RCL shutdown.

Reduce load or radius till RCL resets and resume

operation.

Insufficient oil flow or pressure to extend

cylinder.

Check oil flow, repair if not to specification.

Turn pulsates for a few

seconds

Accelerating swing too rapidly.

Move joystick slowly and smoothly to start and stop

swing.

Turn pulsates

continuously and is slow

Low pilot circuit pressure.

Check and adjust pilot pressure to 500 PSI (3.45

MPa).

Turn will not start

smoothly or increases/

decreases speed

drastically near full

joystick throw

Improper or defective valve spool springs or

burrs on valve spool.

Swing should start to rotate at 100-140 PSI (.7 - 1

MPa) and be at full speed at 300-350 PSI (2.1 - 2.4

MPa). Check for free movement of spool in valve

body, hone spool if required. Replace spool spring

pack if necessary.

Turn moves erratically in

one quadrant

Machine out of level or windy conditions.

Level machine. Operate slowly and carefully in the

wind.

CONDITION POSSIBLE CAUSE POSSIBLE SOLUTION

Loading...

Loading...