CRANE INSTALLATION 1300A

9-14 01-22-2019 Control # 051-08

6. With a WB of 258 inches (655 cm) and a 12 inch

(30.5 cm) set back from the back of the cab to the front

of the T-box, the

1300A requires an AF of about

105 inches (297 cm). Calculate the weight distribution of

the complete machine in order to determine where the

crane center of rotation is in relationship to the center of

the rear axles. A typical mount, on a 258 inch WB and a

12 inch (30.5 cm) set back, positions the crane

centerline of rotation 48 inches (122 cm) behind the

center of tandems. At this location, an AF length

(distance from center of tandems to back of truck frame)

of 105 inches (267 cm) is required. If AF is too long, cut

off excess and remove any crossmembers from back of

truck frame.

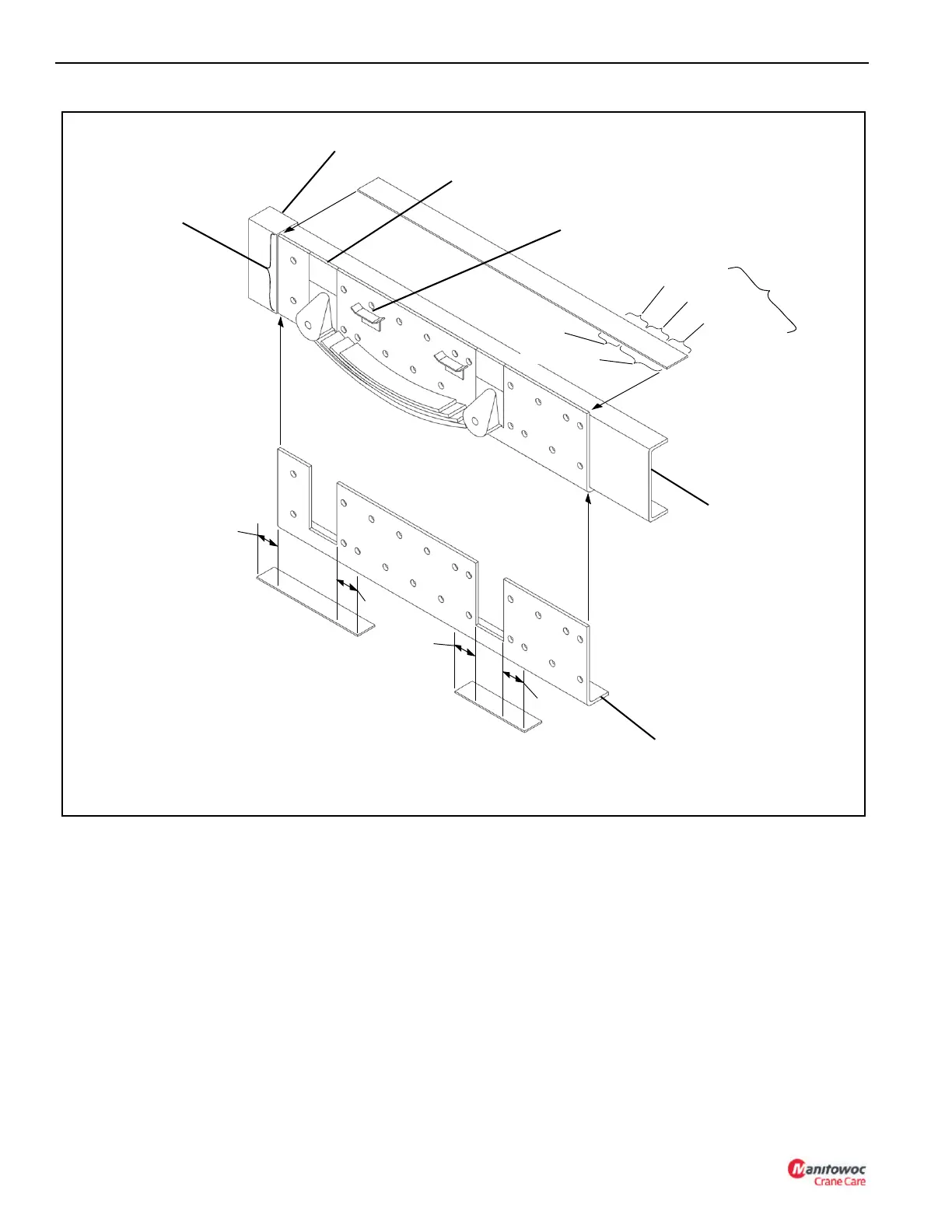

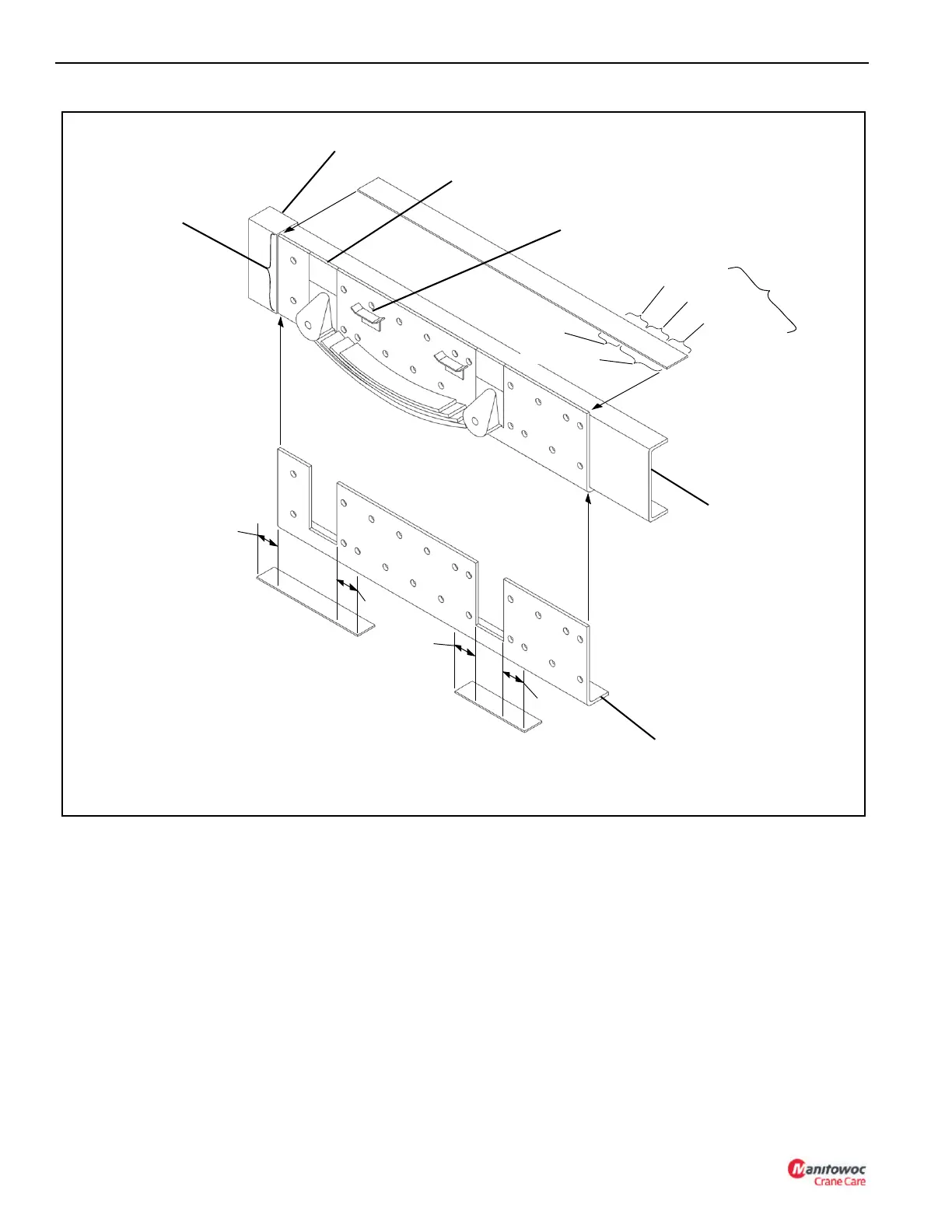

If the AF is too short, the frame needs to be lengthened.

Use channels fabricated from 100,000 psi yield material

that are the same size as the truck frame. Weld these

channels to the ends of the existing truck frame

channels. Bevel the ends of the channels to get 100%

weld joints with Grade 90 weld material. Fabricate an

inner channel of the same thickness as the truck frame

channels to span the weld joint for at least 12 inches

(30 cm) on each side of joint. Plug weld this channel to

the inside of the truck frame, then skip weld the inside

edge of the top and bottom flanges to the truck frame

flanges.

Weld 6 (152)

Skip 6 (152)

Weld 6 (152)

Skip 6 (152)

Weld 12 (304)

Reinforcing under crane

Cut outs Replace as much

material as possible. Butt weld

Overload spring stop.

Remove and replace.

S

k

i

p

w

e

l

d

a

l

l

b

a

r

s

w

i

t

h

a

l

t

e

r

n

a

t

e

w

e

l

d

a

l

o

n

g

b

o

t

h

e

d

g

e

s

Truck frame (REF)

Reinforcing (REF)

6 (152)

6 (152)

6 (152)

6 (152)

Butt weld

FIGURE 9-8

NOTE: All dimensions are inches (millimeters)

Loading...

Loading...