HOIST NBT30H-2 SERVICE MANUAL

5-2 03-20-19 Control # 613-06

MAINTENANCE

Inspect the hoist daily for oil leaks, loose bolts, and worn

hoist cable. Check the gearbox and brake oil every 500

hours. Do an oil change every 1000 hours. Refer to

Lubrication, page 8-1. Inspect the hoist from the deck of the

crane. Do not stand on the turret.

Warm-up Procedure

A warm-up procedure is recommended at each start-up and

is essential if ambient temperature is below +40°F (4°C).

Run the crane at idle with the hoist control lever in neutral

and allow sufficient time for the hydraulic system to warm up.

Operate the hoist at low speeds, forward and reverse,

several times to prime all lines with warm hydraulic oil and

circulate lubricant through the planetary gear sets.

Removal

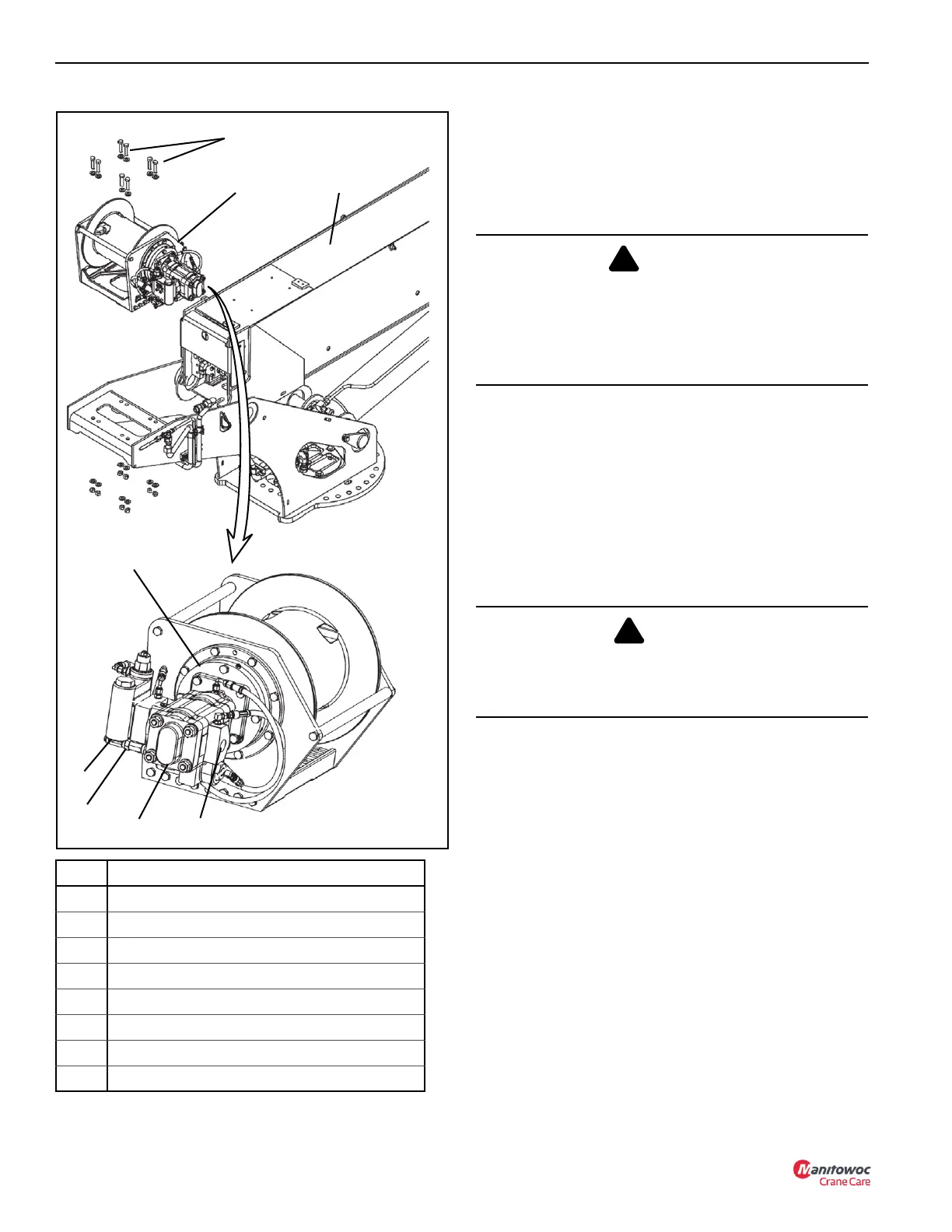

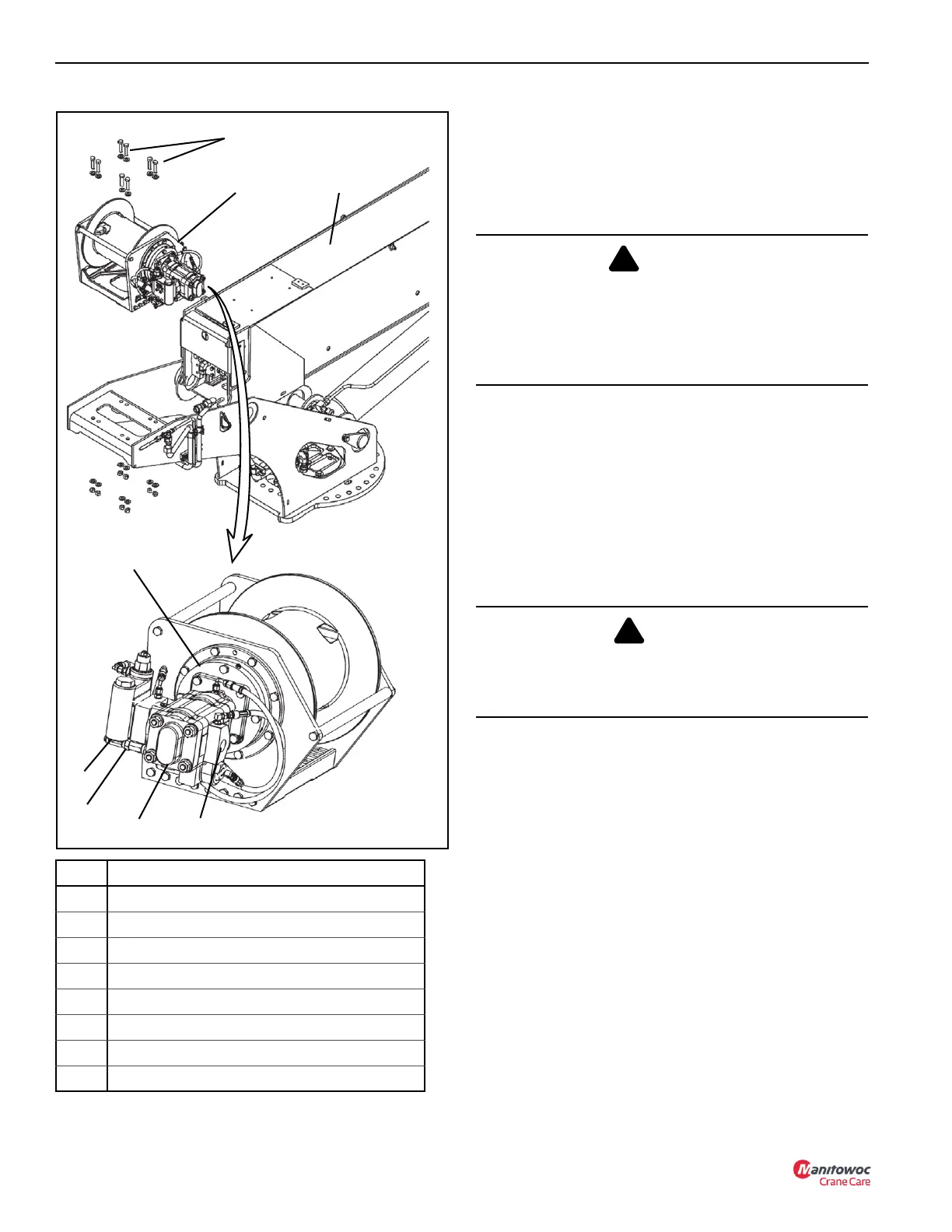

NOTE: See Figure 5-1 for item identification.

1. Remove the cable from the hoist drum.

2. Tag and disconnect the hoist hydraulic lines. Cap and

plug all hydraulic openings.

3. Attach a lifting device to the hoist and take up the slack.

4. Remove the mounting bolts from the hoist.

5. Remove the hoist from the crane with the lifting device.

Hydraulic Hoses

Inspect the hydraulic hoses and replace as required.

Hoist Installation

1. Attach a lifting device to the hoist.

2. Lift the hoist with a lifting device onto the turret.

3. Install mounting bolts and washers.

4. Remove the lifting device.

Item Component

1Hoist

2Brake

3 Motor

4 Mounting Bolts (8 places)

5Boom

6 Case Drain

7 Pressure Port to Raise

8 Pressure Port to Lower

WARNING

Fall Hazard!

Do not, under any circumstances, work at an elevated

height without using proper fall protection as required by

local, state, or federal regulations. Death or serious injury

may result.

WARNING

Crushing Hazard!

The combined weight of the hoist and 390 ft of wire rope is

730 lbs (331 kg). Death or serious injury may result.

Loading...

Loading...