National Crane 03-20-2019 Control # 613-06 8-9

NBT30H-2 SERVICE MANUAL LUBRICATION

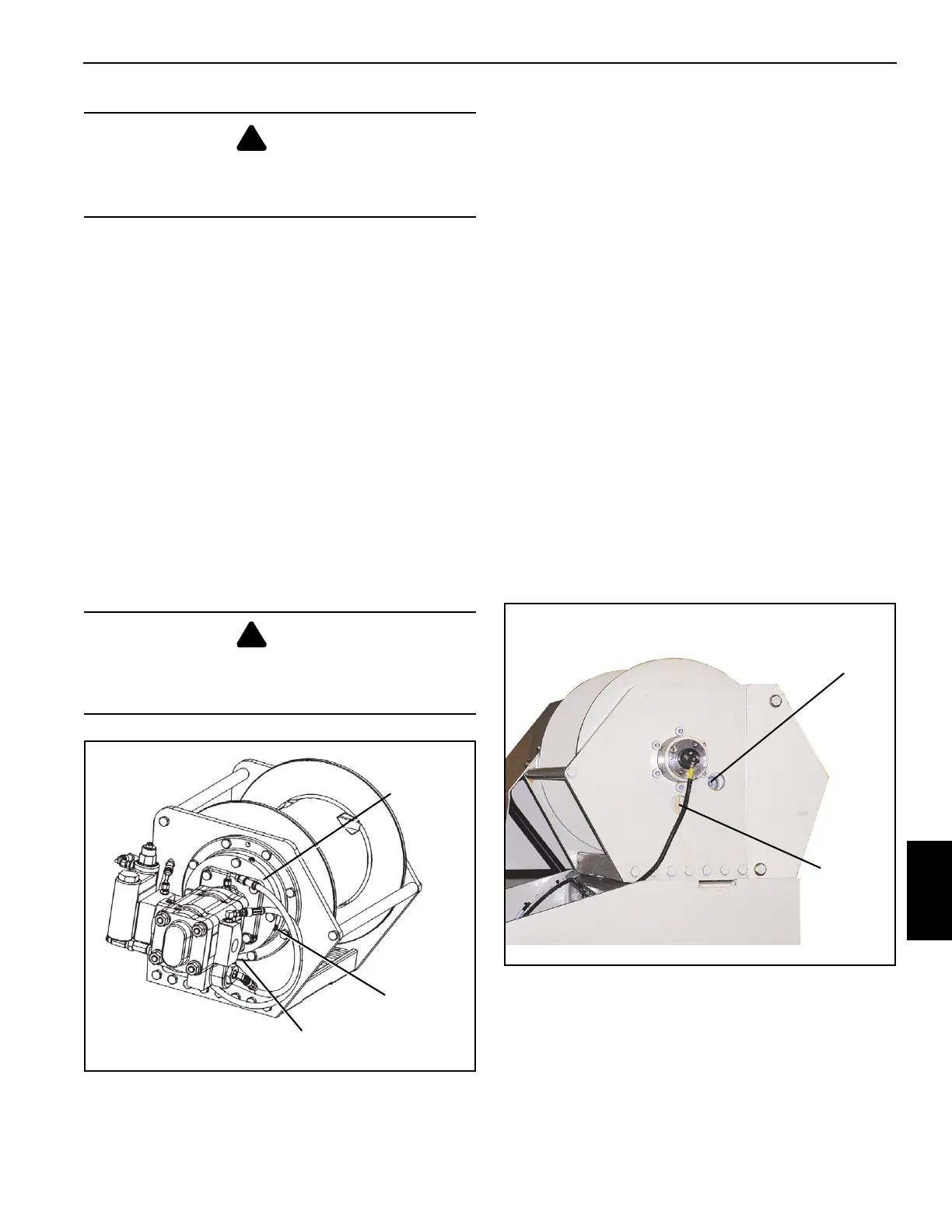

Check Hoist Brake Oil

To check the hoist brake oil, remove the inspection plug

(Figure 8-4) and visually inspect the oil level. The fluid

should be visible within the bottom of the inspection hole. If

more fluid is needed, add through the vent plug hole until oil

is at the bottom level of the inspection hole.

Drain /Add New Hoist Brake Oil

To drain and add new oil, remove the drain plug (Figure 8-4),

inspection plug and vent plug and drain the brake oil.

Reinstall drain plug and add fluid until the fluid is visible to

the bottom of the inspection hole. Reinstall the vent plug and

the inspection plug. See “Lubrication” on page 8-3.The hoist

brake fill capacity is 0.23 liter (.25 quart).

NOTE: Brake lubricants are satisfactory for operation in

temperatures from -23° C to 66° C

(-10° F to +150° F). For operation outside this

range, contact Manitowoc Crane Care for

recommendations.

.

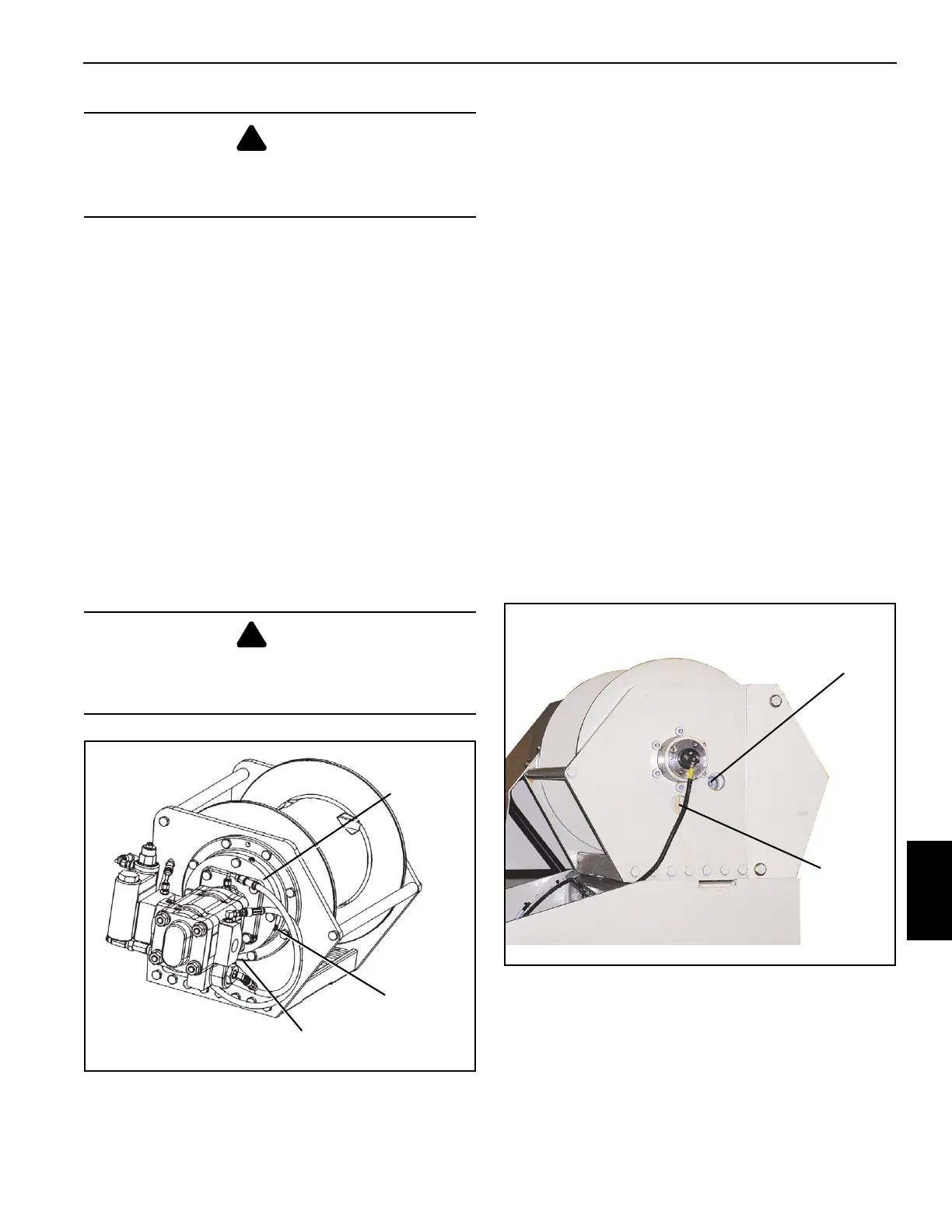

Hoist Gearbox Oil

Check hoist gearbox oil level:

• Rotate the drum until the oil fill/level plug (Figure 8-5) is

visible in the inspection hole.

• Remove the fill/level plug and visually inspect the oil

level. The oil should be level with the bottom of the

inspection hole. If more oil is needed, add and reinstall

fill/level plug.

• To drain and add new oil, remove the vent plug

(Figure 8-5) and then screw a 1” pipe into the drain plug

hole to allow the oil to drain. Remove the drain plug with

a hex head socket and drain hydraulic oil. Remove the

1” drain pipe and install drain plug.

Fill hoist gearbox with oil.

• To fill with oil, rotate the drum so the fill/level port

(Figure 8-5) is visible through the upper hole. Install a 1”

pipe with elbow into the fill hole to assist in adding oil.

Remove fill/level plug with a hex socket and fill gear box

with gear lube oil. See “Lubrication” on page 8-3.

NOTE: Hoist gear lubricants are satisfactory for operation

in temperatures from -23° C to 66° C (-10° F to

+150° F). For operation outside this range, contact

Manitowoc Crane Care for recommendations.

Swing Gearbox and Brake Oil

Check Swing Gearbox oil level

The oil in the gearbox and brake sections is recommended

to be changed after first 50 hours of operation and every

1000 hours or 6 months of usage.

1. Examine the used oil for signs of significant metal deposits.

DANGER

Do not, under any circumstances, work at an elevated

height without using proper fall protection as required by

local, state or federal regulations.

DANGER

Do not use EP type gear lubes in the brake section. This

may prevent proper operation and cause the load to fall

resulting in serious injury or death.

FIGURE 8-4

7142

Brake Oil Vent/

Fill Plug

Brake Oil

Drain Plug

Brake Oil

lnspection

Plug

FIGURE 8-5

Gearbox

Oil Drain

(lower

hole)

Gearbox Oil Fill

(upper hole)

7756-2

Loading...

Loading...