National Crane 03-20-2019 Control # 613-06 2-15

NBT30H-2 SERVICE MANUAL HYDRAULIC SYSTEM

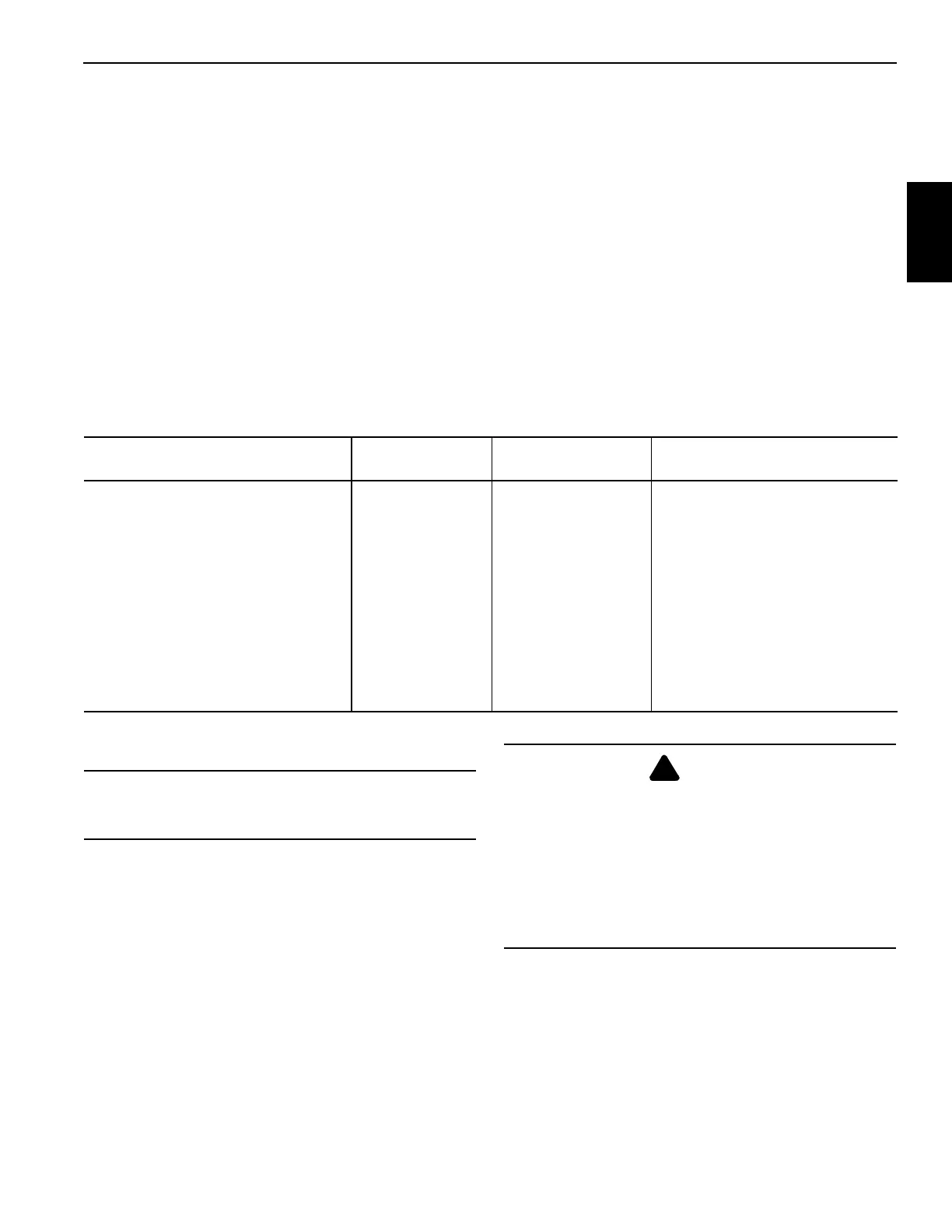

RELIEF PRESSURES

Description

Relief valves protect hydraulic systems from over

pressurization and ensure the components get the proper

pressure and flow. The relief valves for the swing and

telescope circuits are integral to the directional control valve

and are not adjustable. The hoist and lift circuits are set to

the load sense relief valve pressure.

All relief valves are preset at the factory. Certain relief valves

can be adjusted and certain valves are not adjustable, see

the following table for pressure settings and adjustability.

Maintenance

Relief pressures are checked by causing a given circuit to

reach its pressure limit (stall). At the stall point the relief valve

opens and the hydraulic oil is returned to the reservoir.

Hydraulic circuits can be stalled by plugging the work hoses

to the motor or cylinder prior to actuating the control valve. A

pressure gauge placed in the proper line shows the pressure

that the relief valve opens. Release the control lever after

taking each reading.

It is only necessary to hold hydraulic pressure long enough

(usually a few seconds) in the circuit to gain an accurate

reading. Do not overload the hydraulic circuits for long

periods of time.

Use an accurate 0 to 34,500 kPa (0 to 5000 psi) pressure

gauge when adjusting relief valves. To adjust a relief valve,

turn the adjustment screw (in to increase or out to decrease)

until the proper setting is reached. Reservoir oil temperature

is to be 60° - 71°C (140° - 160°F).

CHECKING RELIEF PRESSURE

Preparation

• Start and warm up the engine until the hydraulic oil

temperature reaches a minimum of 60° - 71°C (140° -

160°F).

• Shut down the engine.

Relief pressure for the hoist hydraulic circuits is controlled by

the load sense relief valve located on the directional control

valve (Figure 2-2); this relief valve is not adjustable.

The load sense relief and maximum pressure can be

checked by performing the following steps.

Hydraulic Circuit

Pressure

MPa (PSI)

Tolerance

kPa (PSI)

Location

Telescope In Relief (Not Adjustable) 19.65 (2850) ±689 (±100) Directional Control Valve (Preset)

Telescope Out Relief (Not Adjustable) 19.65 (2850) ±689 (±100) Directional Control Valve (Preset)

Outrigger Circuit Maximum Pressure 20.68 (3000) ±344 (±50) Relief Valve On Pump

Outrigger Circuit Beam Extension 6.89 (1000) ±344 (±50) Front Outrigger Control Manifold

Swing Circuit (Not Adjustable) 20.5 (3100) ±689 (±100) Directional Control Valve (Preset)

Load Sense Relief 26.2 (3800) +2.06 (+300) Relief Valve On Pump

Load Sense Standby 2.48 (360) ±172 (±25) Relief Valve On Pump

Pump Compensator 25.15 (3650) ±689 (±100) Relief Valve On Pump

Options (If Equipped) 17.2 (2500) ±689 (±100) Directional Control Valve (Preset)

CAUTION

Do not hold the relief valve open for more than one minute

at a time. Damage to the hydraulic system may result.

WARNING

High Pressure Hazard!

Pressurized hydraulic fluid can cause serious injury. Be

careful when removing plugs or restrictions from

pressurized hydraulic systems suspected to have

entrapped air.

Fluid injected into skin must be surgically removed within

a few hours by a doctor familiar with this type of injury or

gangrene will result.

Loading...

Loading...