MASSO

MASSO Documentation

17.3. Torch Touch (floating head) Signal

The torch touch signal is used to find the top of the workpiece before starting a cut. Generally a switch or

sensor is mounted on Z axis floating head, this input is then used internally by MASSO to automatically offset

the Z axis gap from the switch / sensor. This input is used with G38.2 command.

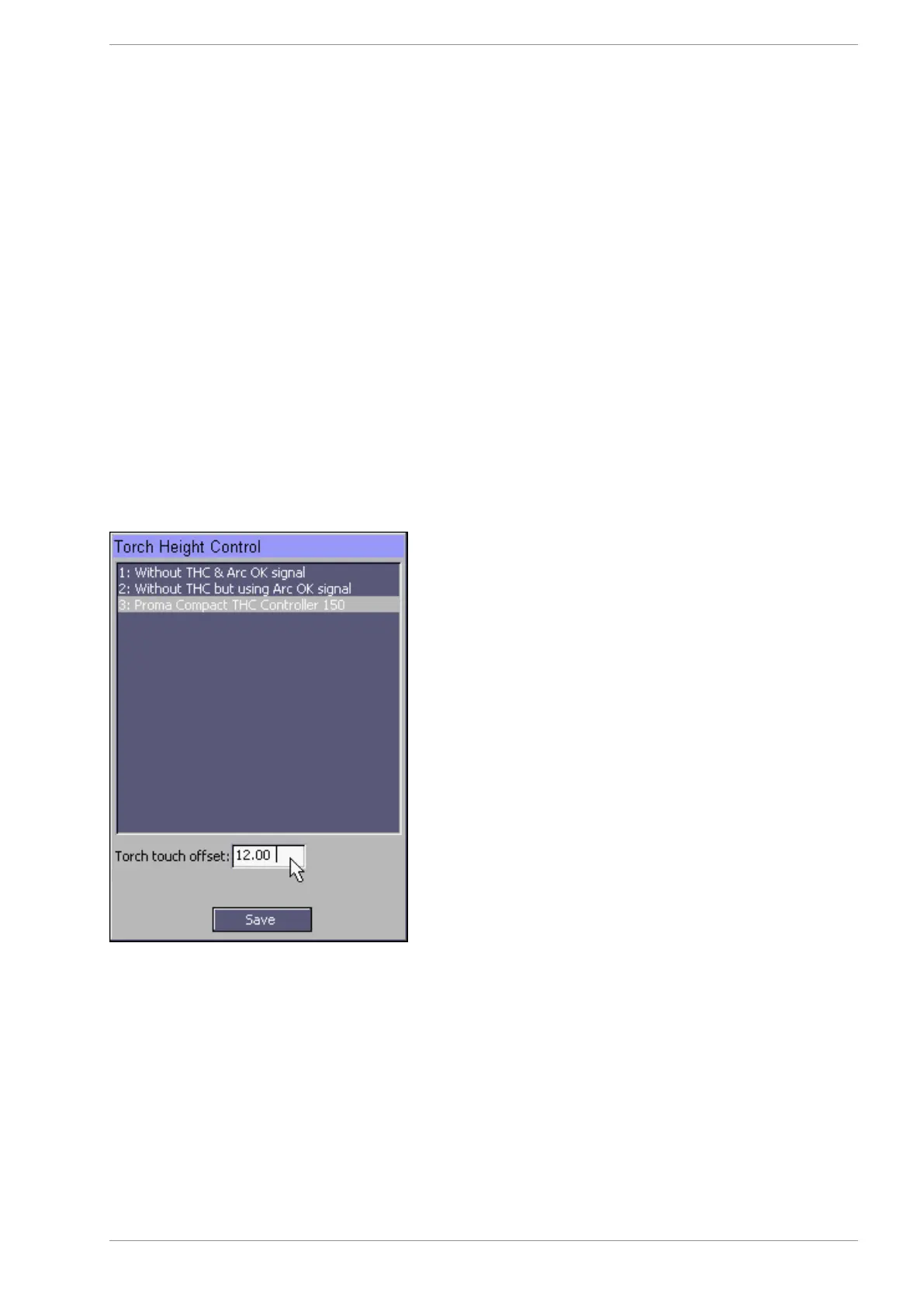

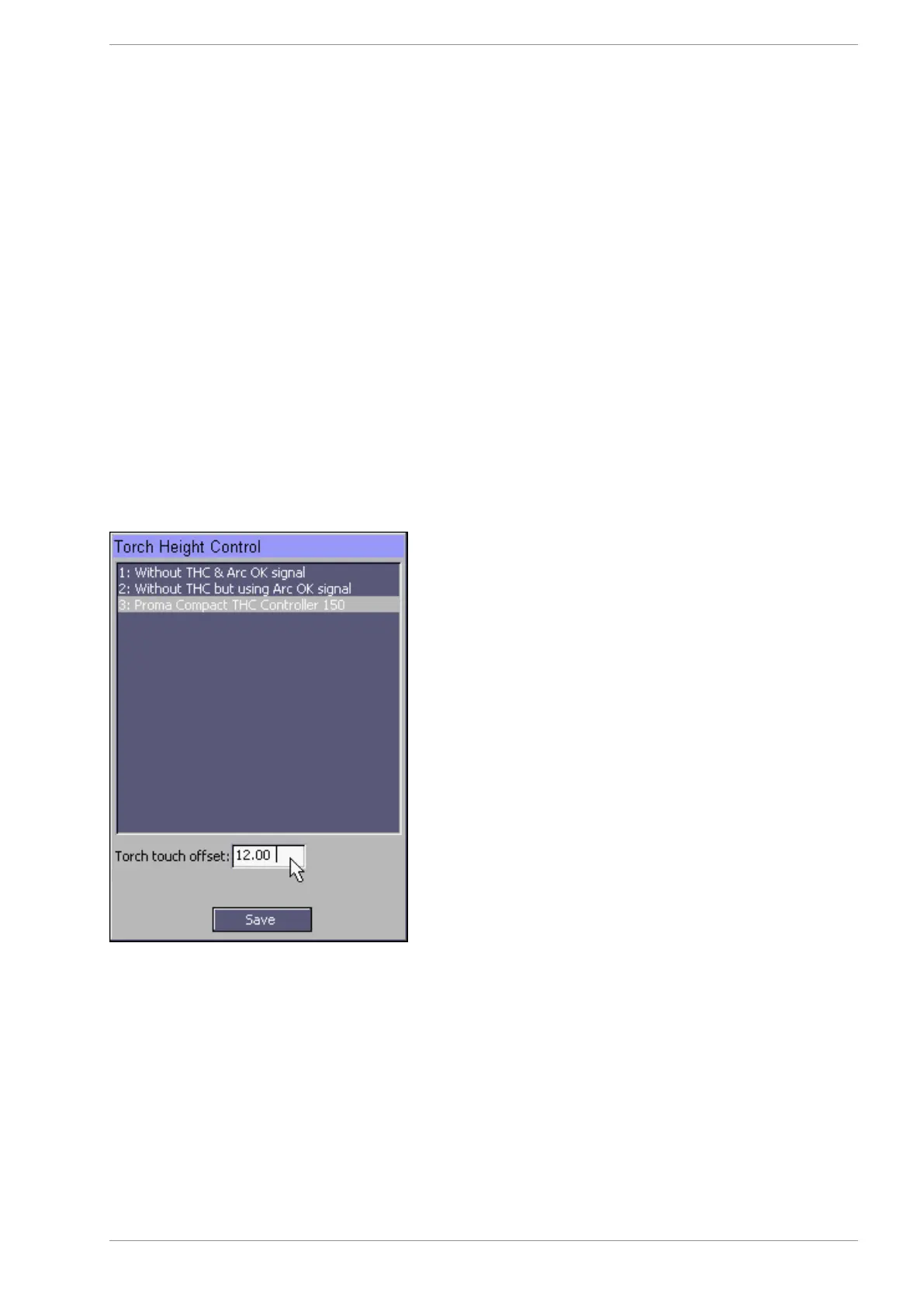

Floating head gap calibration

As each machine floating head gap between the switch / sensor to the torch tip is different, you can enter the

distance in the F1-Setup screen under Torch Height Control settings.

By setting this value MASSO will internally offset this to automatically position the torch touch position, this

also saves time and avoids confusion setting the offset values in CAM software.

Wiring example

Below is a simple wiring example showing how to wire a switch. A 5 to 24 VDC signal can be used.

v5.18 - 08 Apr,2021

www.masso.com.au Page 449 of 477

Loading...

Loading...