Indications concerning residual risks

Even though the rules for “good manufacturing practice” and the provisions of law which regulate manufacturing

andmarketingoftheproducthavebeenimplemented,“residualrisks”stillremainwhich,duetotheverynature

oftheappliance,ithasnotbeenpossibletoeliminate.Theserisksinclude:

Residual risk of electrocution:

Suchriskpersistsifyouhavetooperateelectricaland/orelectronicdevicesundervoltage.

Residual risk of burning:

Suchriskpersistsiftheoperatorcomesaccidentallyintocontactwithmaterialsathigh

temperature.

Residual risk of burning due to material leak

Suchriskpersistsiftheoperatorcomesaccidentallyintocontactwithleakingmaterialat

hightemperature.Overlledcontainerswithliquidsand/orsolidsthatchangemorphology

duringheating(switchingfromsolidtoliquidstate),maycauseburns,ifusedimproperly.

Duringwork,thecontainersshouldbeplacedatlevelsthatensuregoodvisibility.

Residual risk of explosion

This risk remains when:

•ifthereisgasodourintheroom;

•useoftheequipmentinatmospherecontainingsubstancesatriskofexplosion;

•useoffoodstuffinclosecontainers(suchasbarrelsandboxes),thatarenotsuitablefor

such purpose.

Residual risk of re

This risk remains when:

•usingwithammableliquids(suchasalcohol).

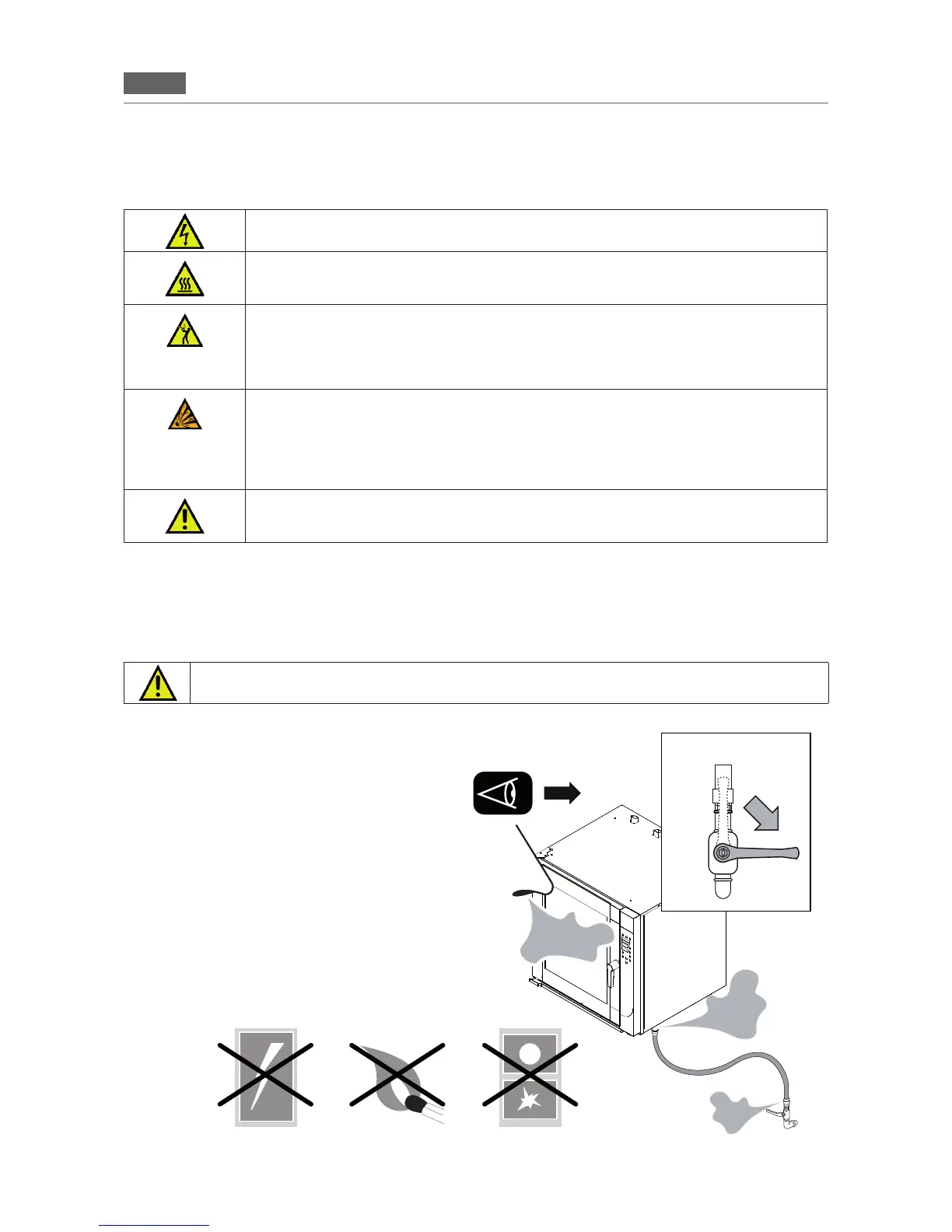

A

B C D

•

Immediatelystopthegassupply(Closethe

networktap,detailA).

•

Ventilatetheroomimmediately.

•

Donotoperateanyelectricaldeviceinthe

environment(DetailB-C-D).

•

Donotoperateanydevicewhichcouldpro-

ducesparksorames(DetailB-C-D).

•

Use a means of communication that is ex-

ternal to the environment where there is a

smell of gas to warn the relevant entities

(electricityoperatorand/orre-ghters).

What to do when there is a gas odour in the area

If there is a smell of gas in the environment, it is mandatory to urgently imple-

ment the procedures described below.

Loading...

Loading...