30

ww

ww

rr

rr

rr

rr

rr

rr

rr

qq

qq

ee

ee

Service manual for medifa 6000 mobile operating tables, version 2.0

Components column / top frame

4.8 Replacing the batteries

To replace the rotary valves of the table, first remove the

cladding. Please refer to the relevant chapters of this

manual for instructions!

First the connecting cables of the two adjustment motors

on the rotary valve must be removed.

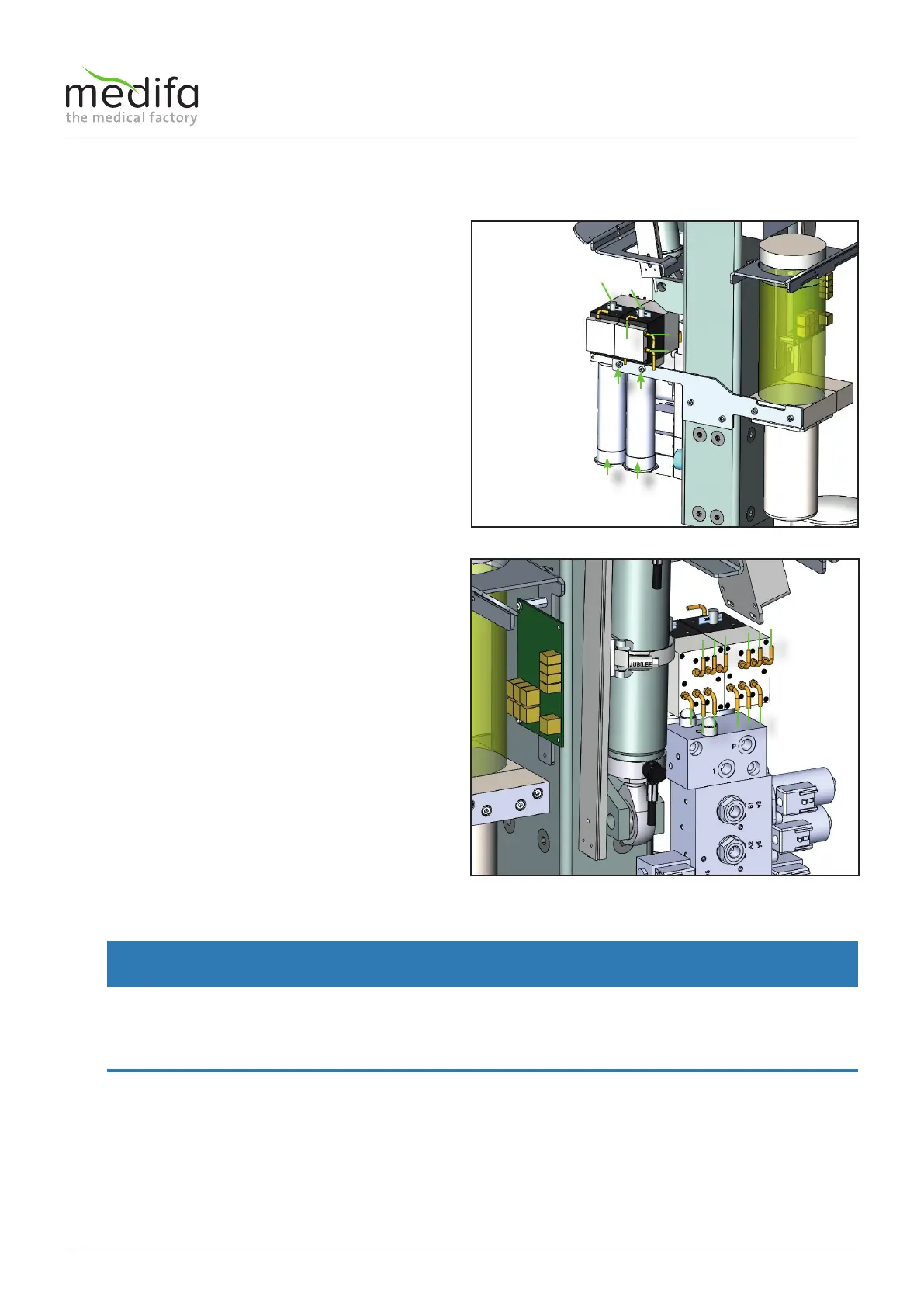

To do this, pull down the two transparent protective

tubes [1] on the rotary valve.

Proceed carefully so as not to damage the cables!

If the protective tubes are off, the red and the blue

connecting cable can now be disconnected from the

adjustment motor. Document the laying of the cables to

bring them back to their original position when installing

them. Repeat this procedure for the second motor as well.

Next, the entire valve block itself can be unscrewed from

the table. To do this, remove the two screws [2] on the

bracket.

After unscrewing the valve block from the table, the two

forked photoelectric sensors [3] on the top of the valve

block should be removed.

To do this, loosen the two plastic screws of the respective

forked photoelectric sensor.

Now that all electrical connections on the valve block

have been removed, the valve block should hang

exclusively on the hydraulic hoses [4].

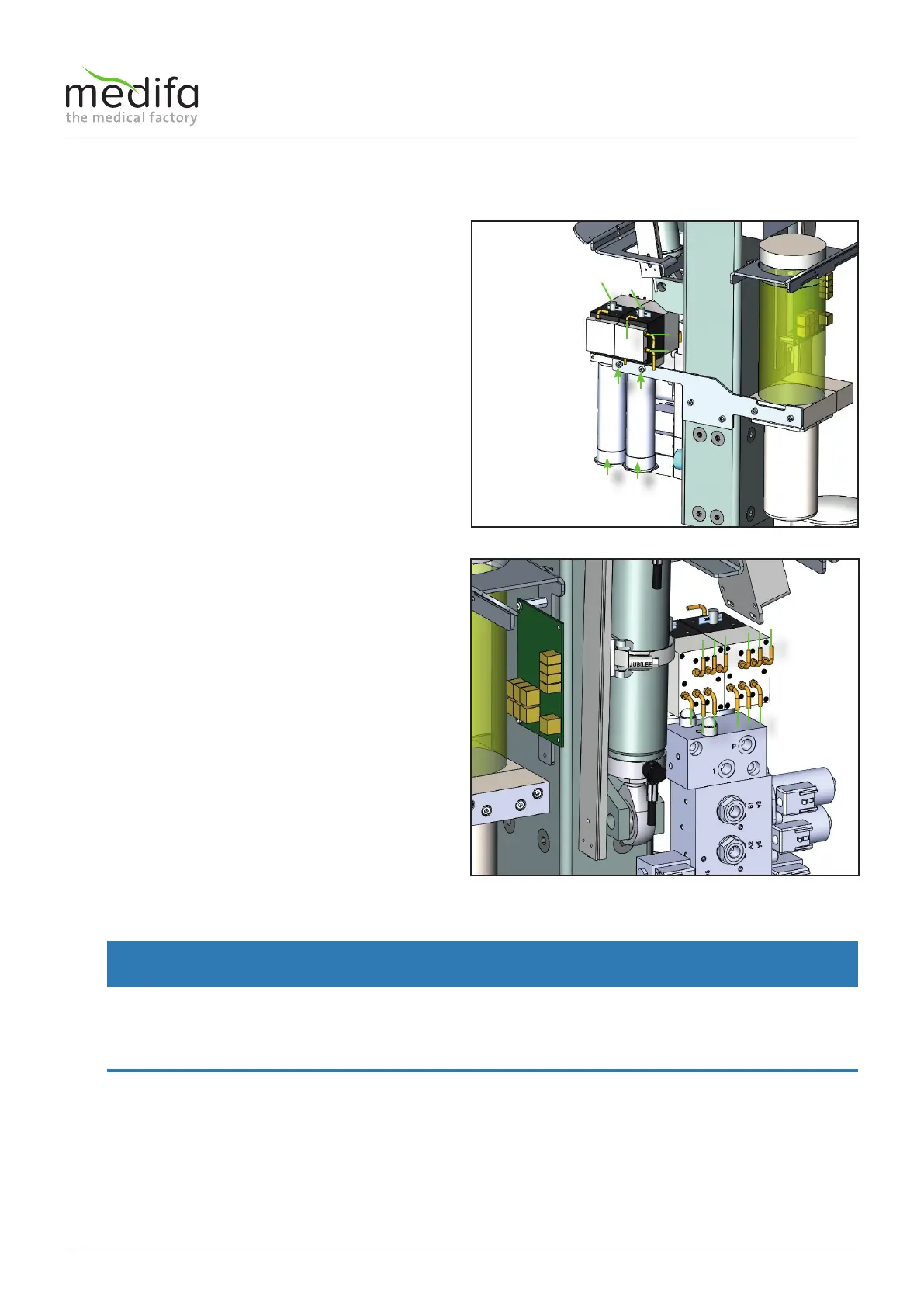

Before you can now start removing these hoses [4], the

entire upper frame of the table must be supported so

that the pressure is taken off the cylinders. To do this,

clamp squared timbers or similar under the lying surface.

WARNING

All cylinders of the table which are under pressure should be retracted as far as possible. It is important that the height ad-

justment is completely retracted. In addition, the entire lying surface of the table must be supported against sagging before

you remove the hydraulic hoses [4] from the valve block, otherwise oil can escape from the hoses under high pressure and

the lying surface would sag!

After the table top is well supported, you can start to detach the hoses from the block on both the front and back sides. To do

this, simply remove the screw of the holding plate directly next to the hydraulic hose [4]. Document the position of the hoses

[4], using the hydraulic diagram, before you start dismantling. This will later make it easier to fit the hoses to the new valve

block [2].

Figure 46

Figure 47

Loading...

Loading...