SECTION 3

TROUBLESHOOTING

22

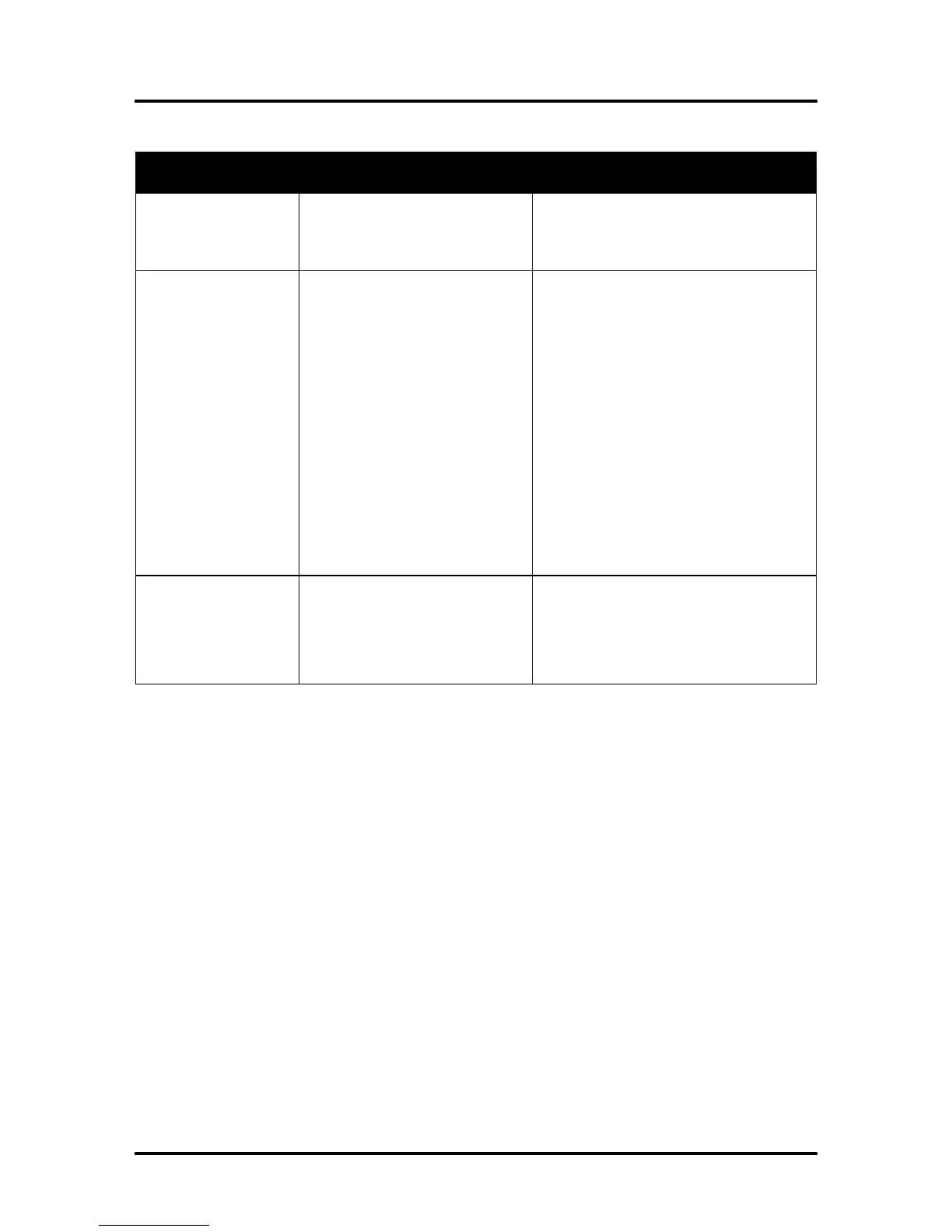

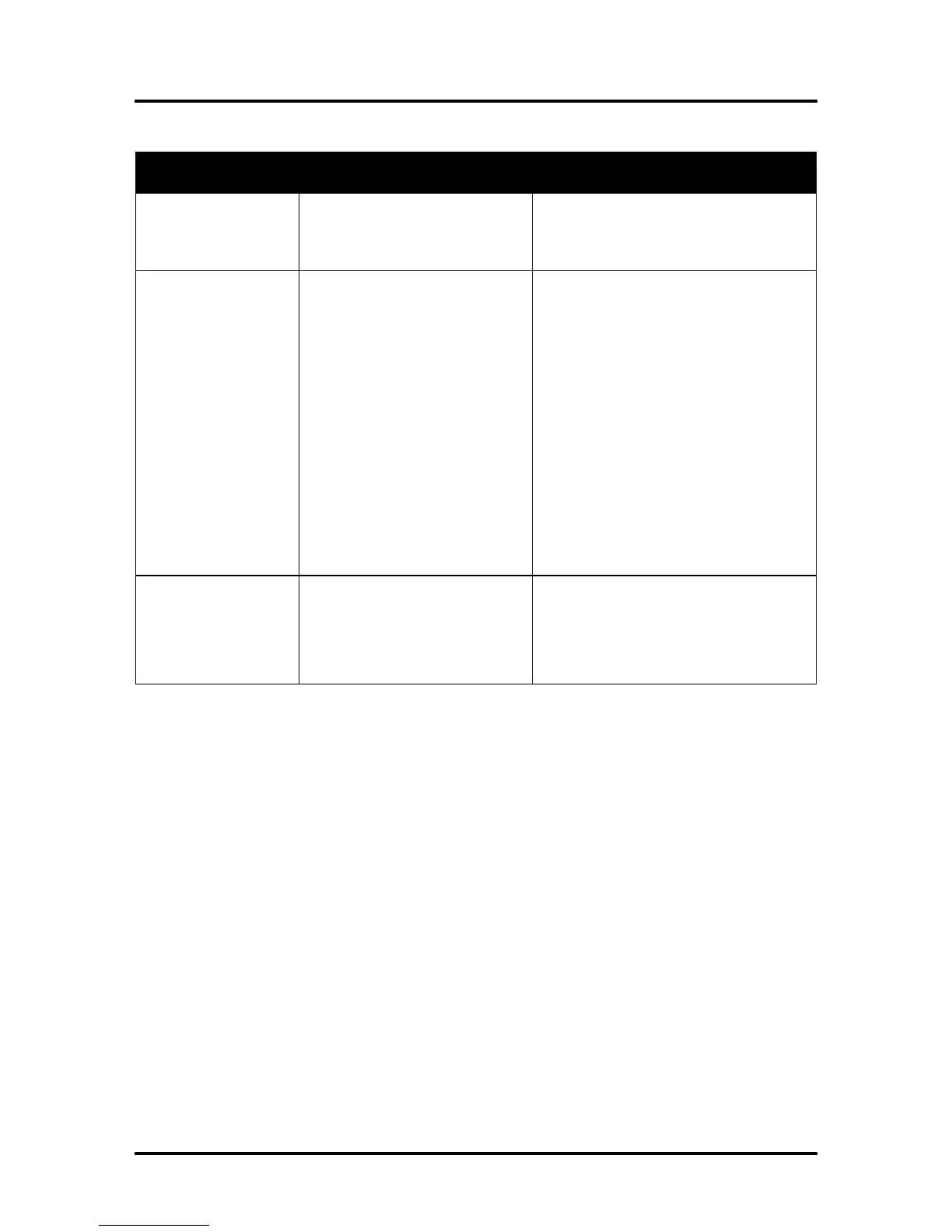

Feeding Problems (continued)

CONDITION PROBLEM SOLUTION

being damaged as it

travels through print

engine area

Media is hitting the limits inside

the print engine.

Make sure Adjustable Media Side Guide

is at least 1/8” away from side frame.

If stock is over 9.5” wide; you need to use

narrower stock.

end of job and or last

piece does not exit the

Print Engine.

Note: It is normal to

get blanks at end of job

when using “Max

Throughput” mode.

Tip: If last page stops

inside Print Engine, the

printer may stay in the

“Maintenance Mode”

until the media is

cleared from the print

Toolbox “Cutsheet Feeding

Mode” is set to Max Throughput.

Feed Sensor is

dirty/dusty/damaged

Improper Connection at I/O board.

Improper Connection of J703 at

Main PCB

Damage to cable that runs

between S4 on I/O board to J703

on Main PCB.

In the Max Throughput mode the printer

will feed 1 or 2 blanks at end of job. Set to

“Safe Feed” to eliminate this issue.

Check/Clean/Replace Feed Sensor and or

Reflector.

Check Connections at I/O board.

Check to be sure J703 at Main PCB is

connected to proper socket.

Repair cable.

Faster than Print

Engine. (Causing

media to buckle/jam

as it enters

Problem with Feeder Encoder

Sensor Signal.

Check Connection to Encoder Sensor.

Clean Encoder Wheel.

Check Adjust Encoder Sensor Position on

Encoder Wheel.

Loading...

Loading...